Ceramic matrix composite bolt prefabricated body-structure integrated design method

A composite material and design method technology, applied in computer-aided design, calculation, instrument, etc., can solve the problems of different calculation results, inaccurate strength, and failure to consider the influence of ceramic matrix composite material structure, so as to achieve accurate model High degree of accuracy, improve prediction accuracy, and quickly modify the effect of the model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in further detail now in conjunction with accompanying drawing.

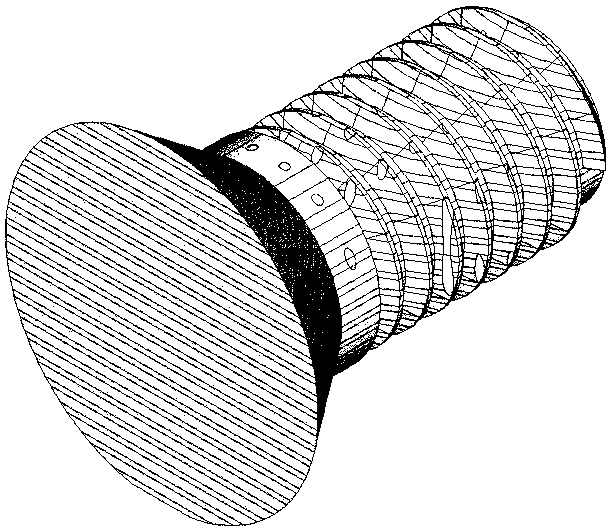

[0037] A ceramic matrix composite material bolt prefabricated body-structure integrated design method, the specific steps are as follows:

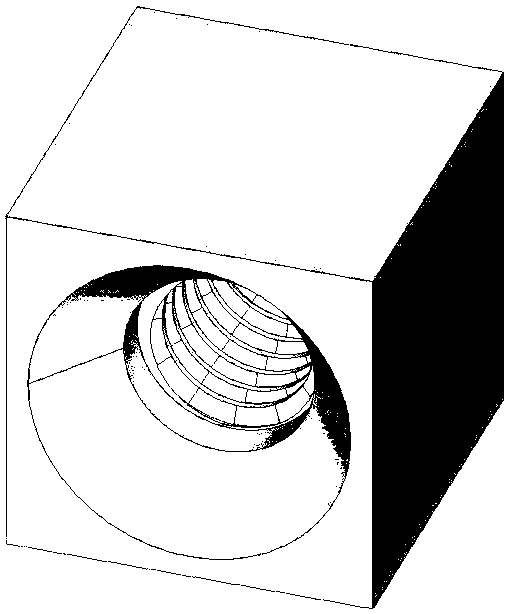

[0038] 1. Prefabricated body modeling

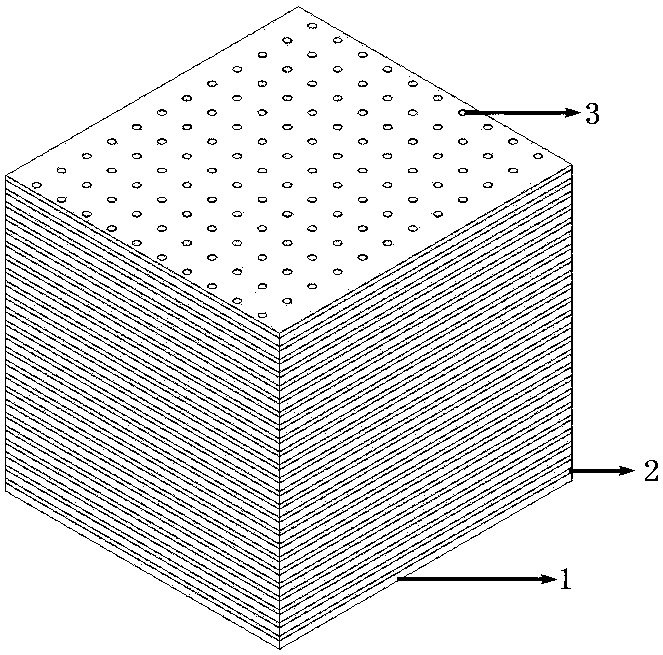

[0039]1) Set the layup thickness h, simplify the layup of needle-punched ceramic matrix composites into a rectangular flat plate with length, width and thickness respectively L, W and h, and stack n layers of layup along the thickness direction to form a length, width and thickness of Laminate model for L, W, and H, where H equals n*h.

[0040] 2) Set the diameter r and distance d of the needled fiber bundle, and then establish a cylinder model with a diameter r and a height H at equal intervals in the direction perpendicular to the layup as the needled fiber bundle model.

[0041] 3) Boolean operations are performed on the ply model and the needled fiber bundle model, and the ply model is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com