Parameterization modeling method for turbine blade root extension segment profile

A turbine blade and root section technology, applied in the field of parametric modeling of the inner shape of the turbine blade root section, can solve the problems of large differences in shape characteristics, ineffective parametric design of the root section, and lack of root section modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Describe the present invention below in conjunction with specific embodiment:

[0040] The present invention is now described by taking the parametric design process of the root section of a certain type of blade as an example. The CAD software design environment of this example is UG NX7.5 software.

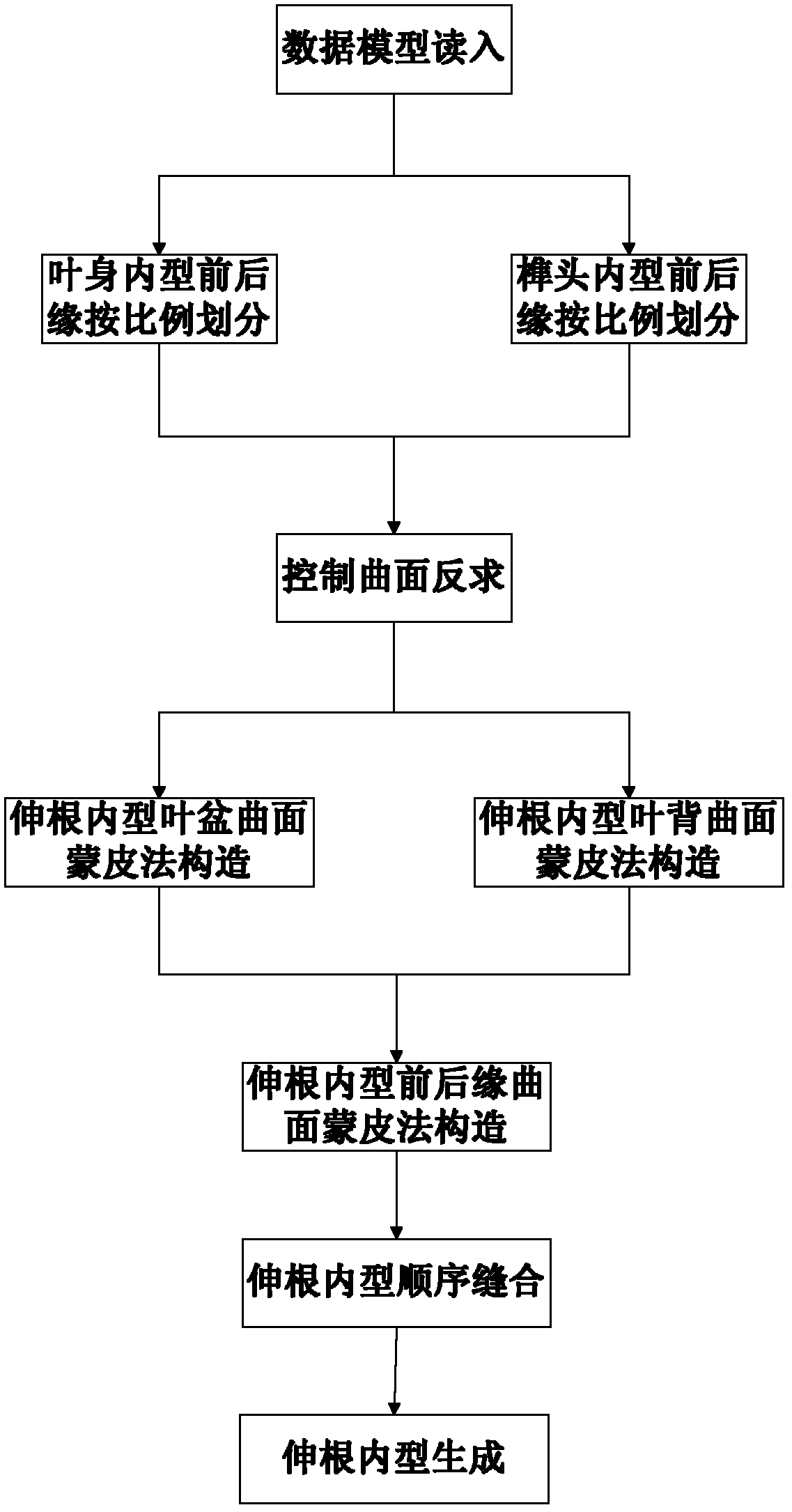

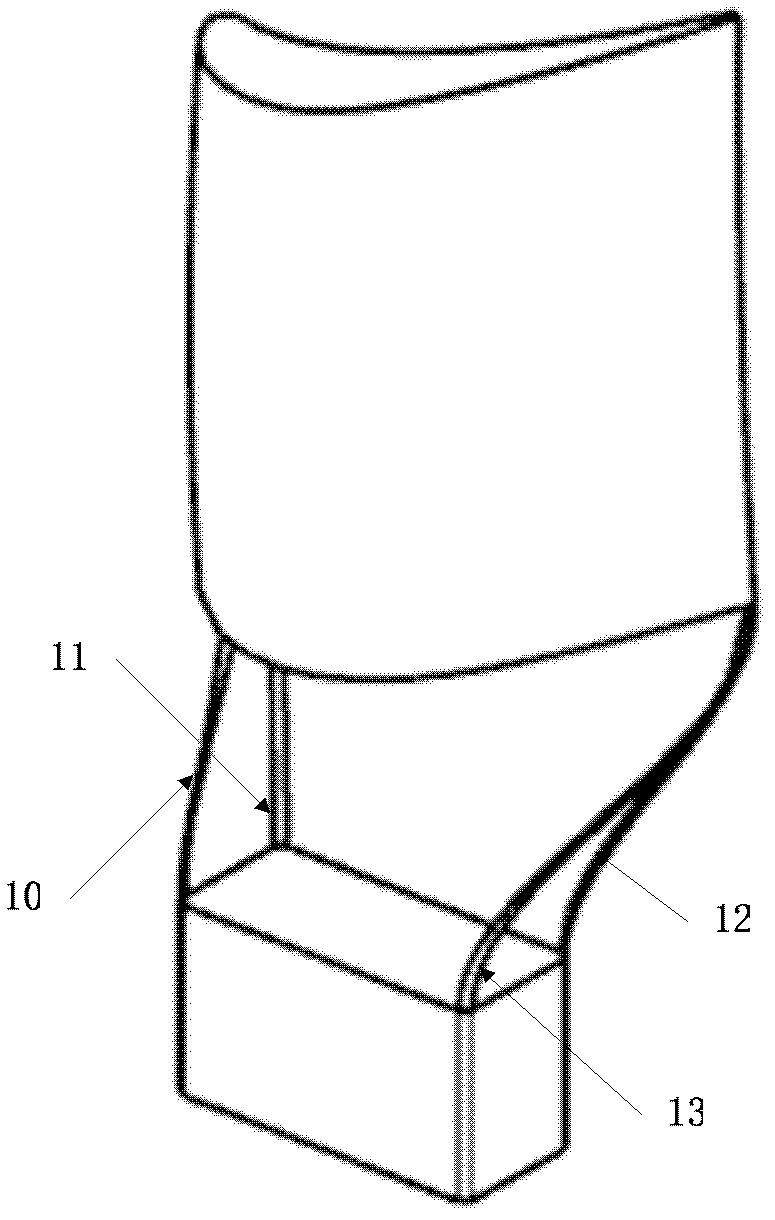

[0041] In this embodiment, a method for parametric modeling of the internal shape of the root section of the turbine blade adopts the following steps:

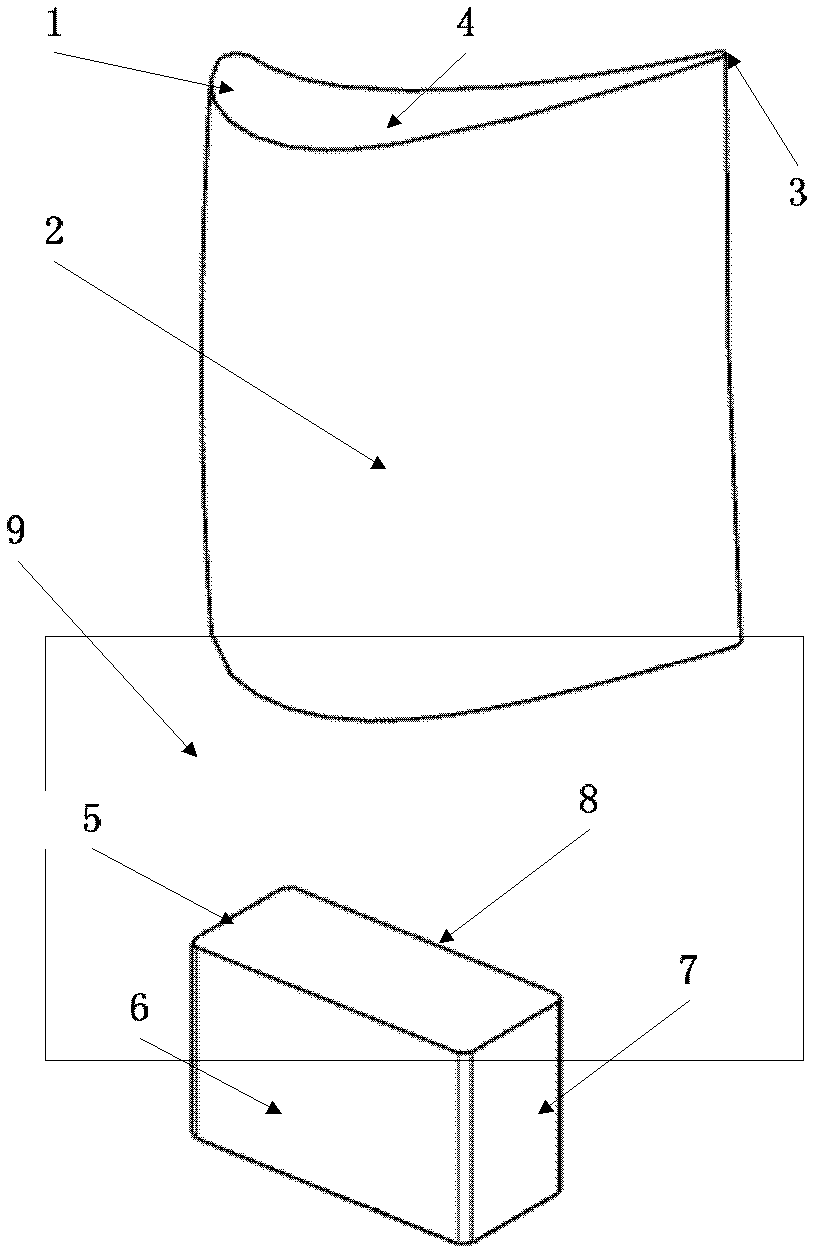

[0042] Step 1: If figure 1 As shown in Fig. 1, the airfoil internal shape data model and the tenon internal shape data model of the turbine blade are imported into the 3D modeling software, wherein the airfoil internal shape data model and the tenon internal shape data model are represented by U and V double parameters;

[0043] The blade body internal shape section line in the blade body internal shape data model is divided into four sections, which are respectively the blade basin curve, the blade back curve, the leadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com