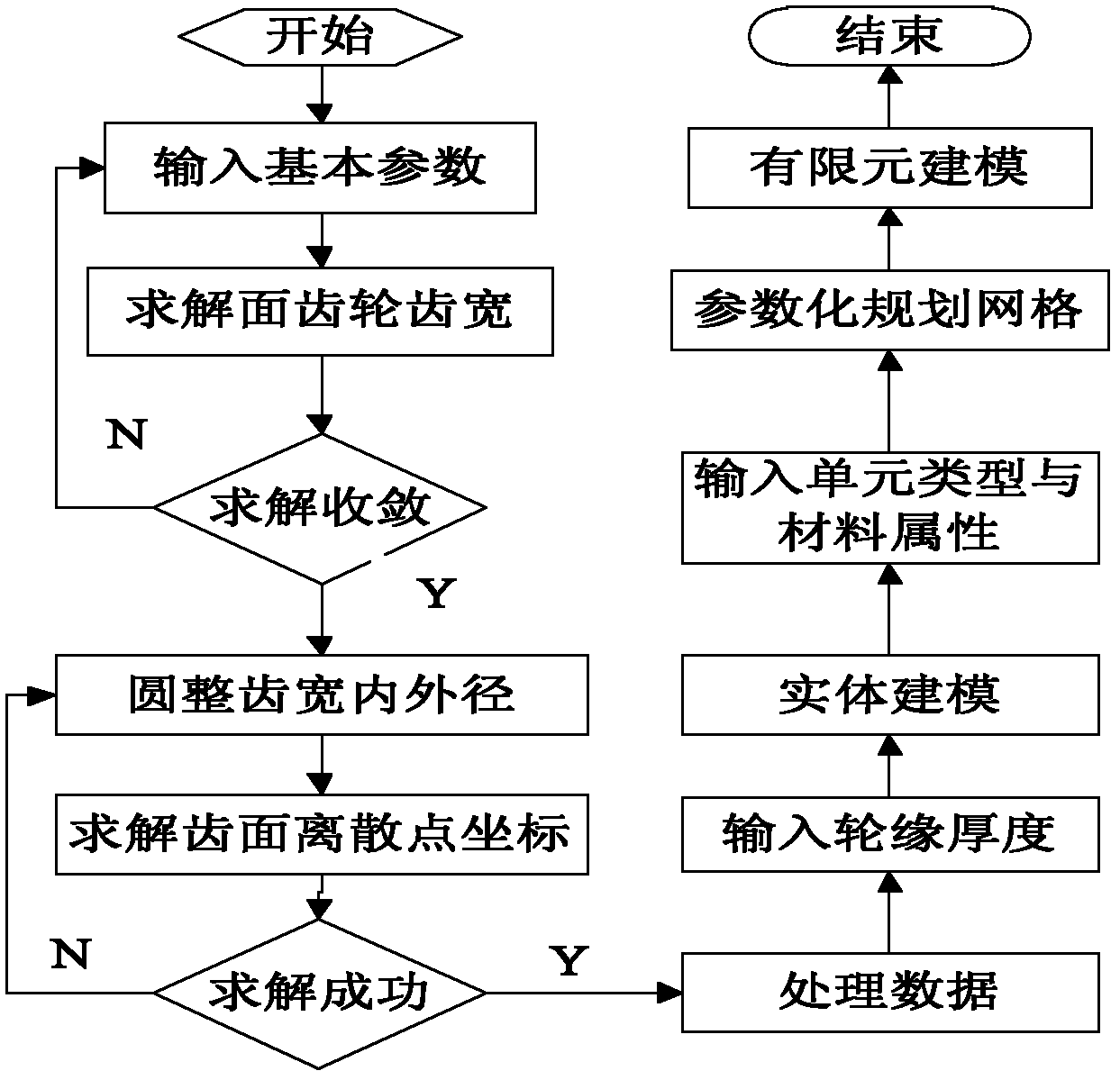

Parametric modeling method of face gear teeth

A parametric modeling and face gear technology, applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of difficult to achieve parametric modeling, and the accuracy of the tooth surface is not very high, so as to reduce the workload , Improve work efficiency and achieve parameterized effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

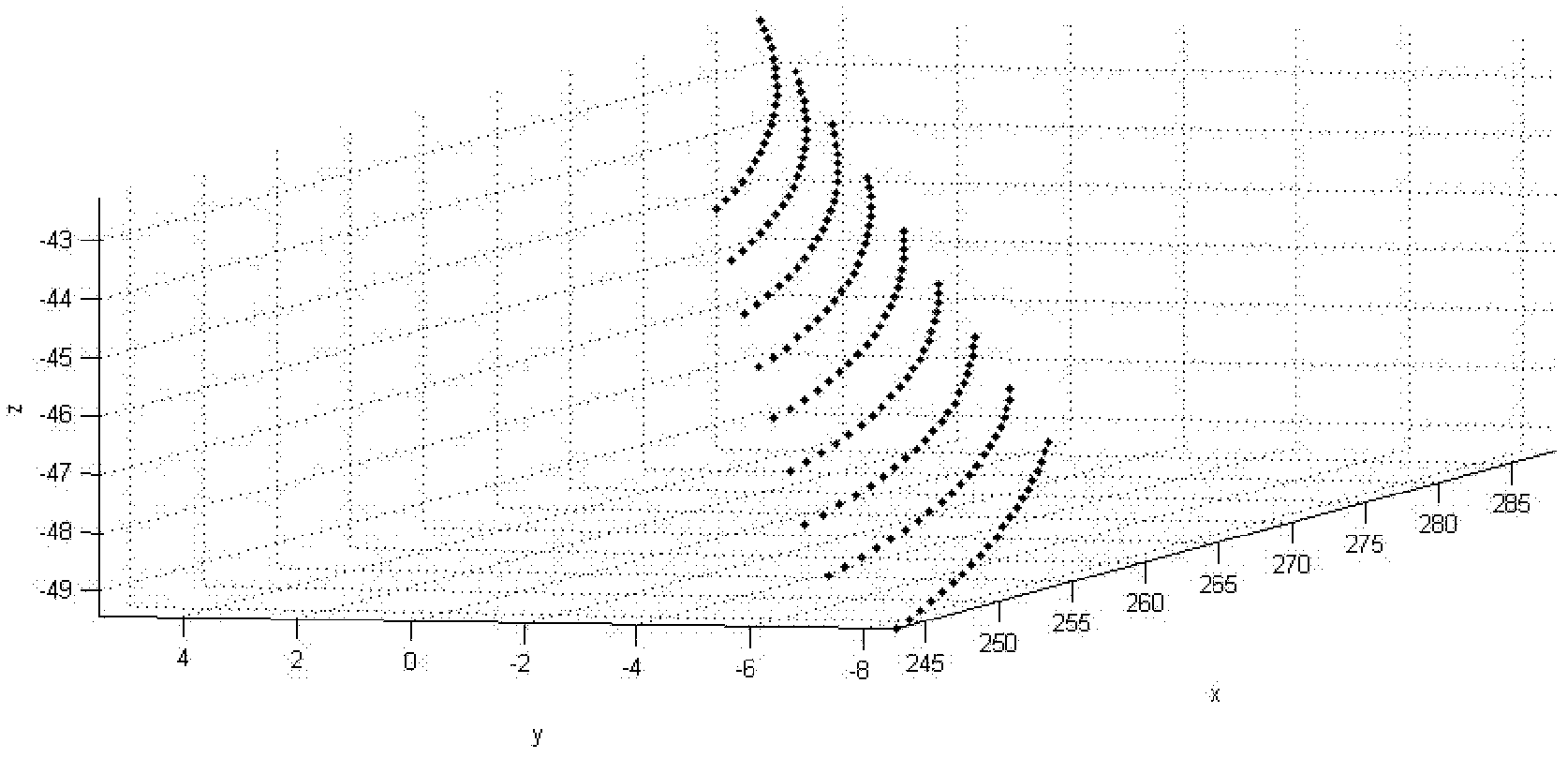

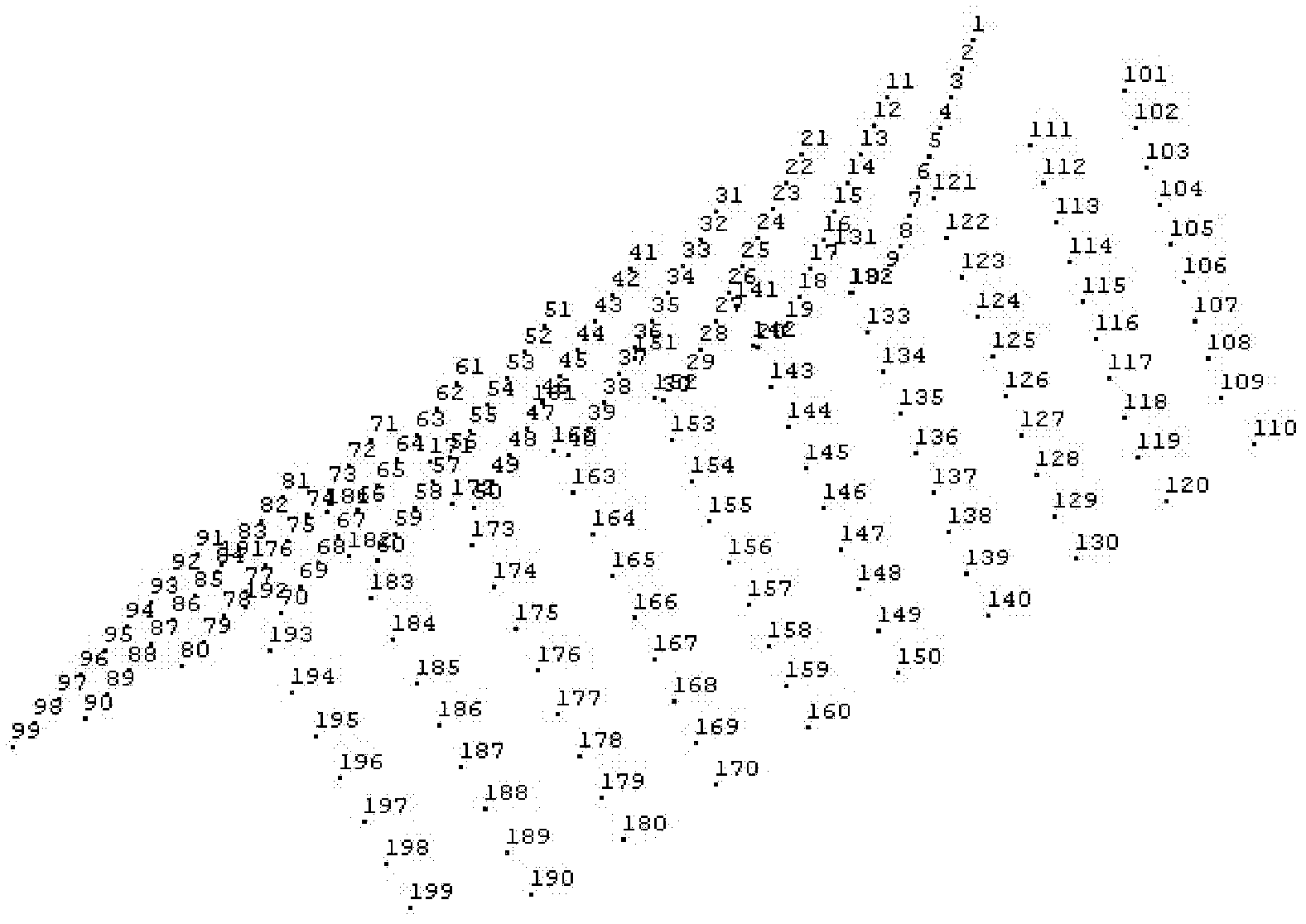

[0054] 1. Numerical calculation of tooth surface of face gear

[0055] Table 1 Design parameters of orthogonal face gears

[0056]

[0057] 1.1) As shown in Table 1, collect basic parameters. According to the undercut limit point theorem in the principle of gear meshing, the minimum inner diameter of the face gear is 128.4458mm by solving the nonlinear equation set; according to the phenomenon that three tooth surfaces intersecting in pairs in space intersect at one point, the face gear is obtained by solving the nonlinear equation set The maximum outer diameter of the tooth surface is 151.6871mm. The maximum outer diameter-minimum inner diameter>18mm, the solution result converges, which meets the requirements of the tooth width.

[0058] 1.2) The tooth width of the gear after rounding must meet: minimum inner diameter ≥ 129mm, maximum outer diameter ≤ 151mm, maximum outer diameter - minimum inner diameter ≥ 18mm. In this case, the minimum inner diameter and maximum out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com