Method for placing chiller in casting process

A cold iron and casting process technology, applied in the field of placed cold iron, can solve the problems of reduced chilling function of cold iron, increased cost of cold iron use, burrs around the cold iron, etc., to achieve lower processing accuracy requirements, improve production efficiency, The effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

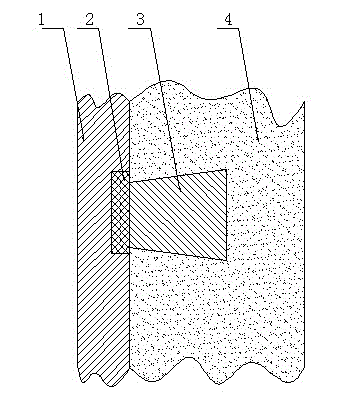

[0009] Such as figure 1 As shown, the method for placing chilled iron in the present invention is to prepare chilled iron 3 according to the quantity and size designed by the casting process, and said chilled iron 3 adopts a circular or polygonal or irregular frustum-like structure in cross section to avoid The loosening of the chill iron 3 during mold opening affects the quality of the casting; then the mold is prepared according to the casting process, and a high-strength magnet 2 is inlaid on the mold 1 corresponding to the position where the chill iron 3 is embedded; The small end of the magnet is adsorbed on the corresponding high-strength magnet 2, placed in the sand box to be made, injected with molding sand and tamped, the cold iron 3 is tightly wrapped, when the mold is opened, the mold 1 is taken out, because the cold iron 3 is in the shape of a frustum , can overcome the adsorption force of the high-strength magnet 2, so the cold iron 3 stays in the sandbox without ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com