Anti-icing control system of wind turbine blade and manufacturing method of wind turbine blade with anti-icing performance

A wind power blade and control system technology, applied in wind power generation, wind power generator components, mechanical equipment, etc., can solve the problems of low thermal conductivity, unsatisfactory deicing effect of large blades, and high requirements for resin thermal deformation temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

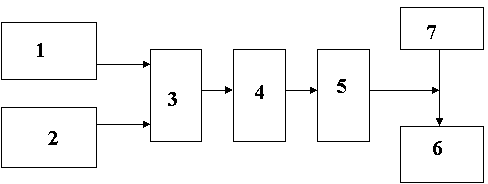

[0060] Such as figure 1 Shown: an anti-icing control system for wind turbine blades, which mainly includes: a monitoring unit, a control unit and a heating unit;

[0061] The monitoring unit includes a temperature sensor (1) installed on the surface of the blade, and a temperature and humidity sensor of the environment where the blade is located.

[0062] (2);

[0063] The control unit comprises a temperature and humidity transmitter (3), a PLC controller (4) connected to the temperature and humidity transmitter (3), and a solid state relay (5) connected to the PLC controller (4);

[0064] The heating unit includes an electric heating material (6) and a power supply (7) connected to the electric heating material (6);

[0065] The temperature sensor (1) and the temperature and humidity sensor (2) are connected to the temperature and humidity transmitter (3) respectively;

[0066] The solid-state relay (5) is connected to the PLC (4) to realize switching on and off of the po...

Embodiment 2

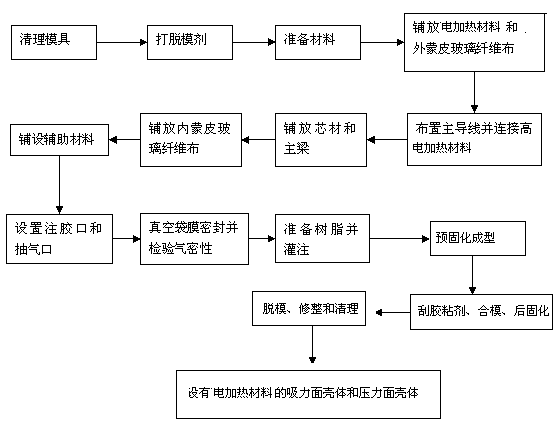

[0070] A method for preparing a wind turbine blade with anti-icing performance, comprising the following steps:

[0071] a. Prepare the suction surface shell and the pressure surface shell provided with the electric heating material by vacuum infusion molding process, and connect the electric heating material to the main lead wire through the branch wire;

[0072] b. Use structural glue to bond the suction side shell and pressure side shell with electric heating material prepared in step a, and the prefabricated shear web into one, to make a semi-finished wind power blade; then trim the semi-finished product, and Paste glass fiber cloth pre-impregnated with resin on the inside and outside of the leading edge and trailing edge of the blade for reinforcement;

[0073] c. Cut and drill the root of the semi-finished wind power blade, then spray a protective coating on its surface, and then install the bolt fasteners at the blade root;

[0074] d. Connect the root of the wind powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com