Intelligent auxiliary designing system for sheet metal components

A technology for auxiliary design and sheet metal parts, applied in the field of intelligent auxiliary design system for sheet metal parts, can solve the problems of heavy design workload, repetitive labor, precipitation, etc., and achieve the effect of improving precision and realizing intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is specifically described below by way of examples.

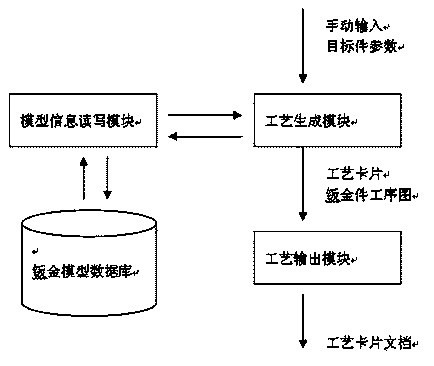

[0018] like figure 1 As shown, the sheet metal parts intelligent auxiliary design system module provided by the present invention includes:

[0019] Sheet metal model database, model information reading and writing module, sheet metal process generation module, process result output module and other functional modules.

[0020] Wherein, the model database includes a process database and a template database, the process database is used to store process flow parameters, and the template database is used to store part parameters.

[0021] Process parameters specifically include: process flow information, processing equipment information, measuring fixture information, processing operator information, and so on.

[0022] The template database stores the basic information of the parts, which are the basic information needed in the process of generating the sheet metal model, such as: part name, ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com