Method for electroplating graphene/carbon fiber by utilizing ionic liquid, product and application

A technology of ionic liquid and carbon fiber, which is applied to the electrochemical variables of materials, material analysis through electromagnetic means, instruments, etc., can solve the problems of unbendable, bulky and expensive medical devices, and achieve good specific surface area and increase specific surface area , the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

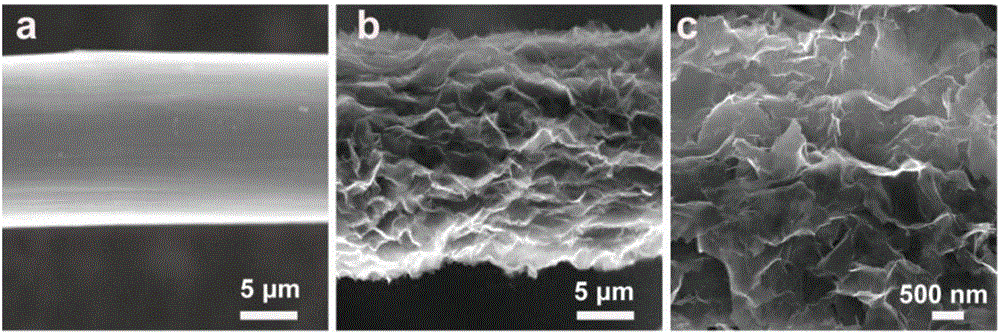

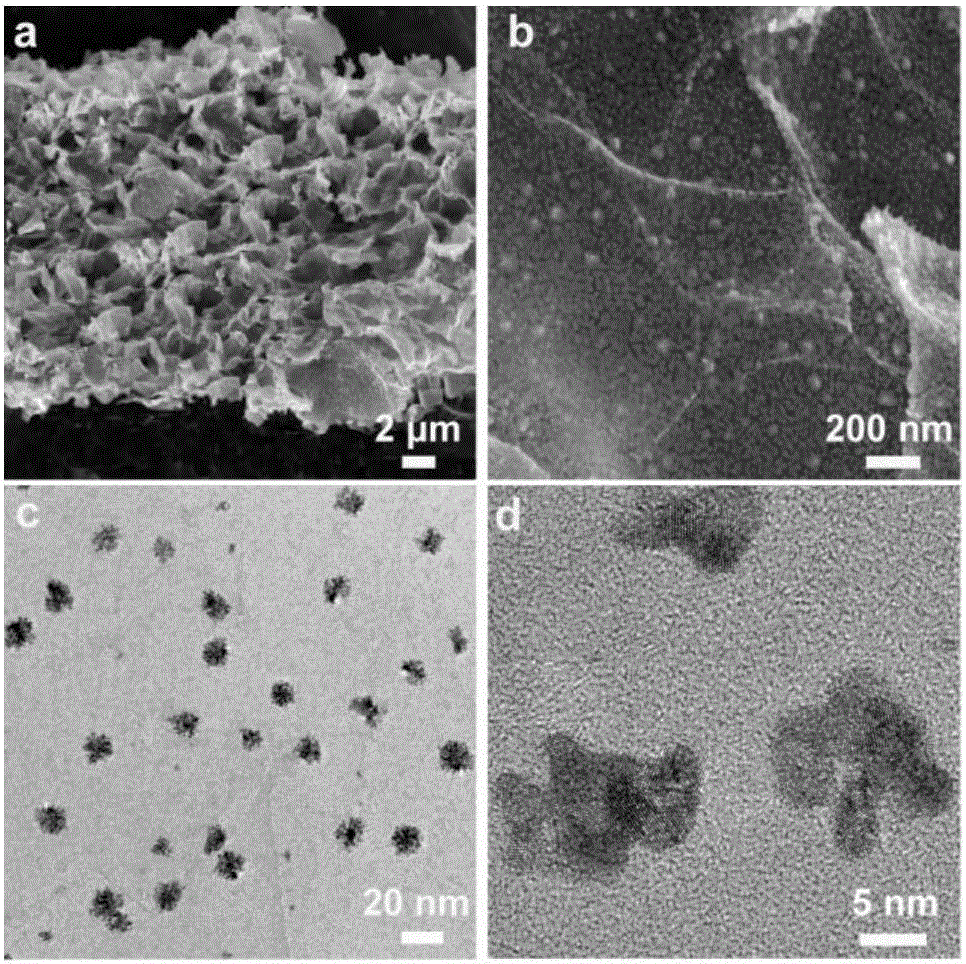

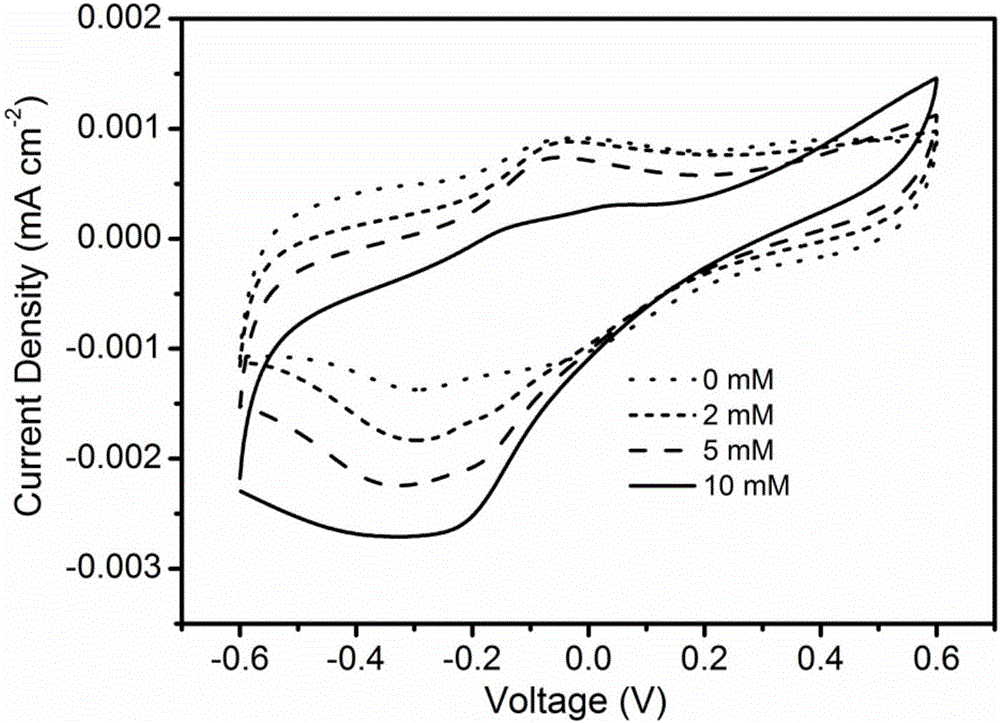

[0037] Include the following steps:

[0038] (1) Select ionic liquid 1-butyl-3-methylimidazolium tetrafluoroborate to prepare a graphene oxide-ionic liquid dispersion with a concentration of 6mg / ml: 10ml of a graphene oxide aqueous solution with a concentration of 6mg / ml Mix evenly with 10ml of 1-butyl-3-methylimidazolium tetrafluoroborate by ultrasonic method, and then place the mixed solution in a vacuum drying oven at 35°C for 3 days to remove moisture.

[0039] (2) Activation of carbon fiber: the carbon fiber was ultrasonically cleaned 3 times with ethanol and water, and then dried. The carbon fiber was used as the working electrode, the platinum mesh electrode was used as the auxiliary electrode, and the saturated calomel electrode was used as the reference electrode. 2 SO 4 (mass percentage concentration can be more than 96%) and HNO 3 (Mass percentage concentration can be more than 64%) In the mixed acid obtained by mixing at a volume ratio of 1:1, under the condition...

Embodiment 2

[0044] Include the following steps:

[0045] (1) Use ionic liquid 1-ethyl-3-methylimidazolium tetrafluoroborate to prepare a graphene oxide-ionic liquid dispersion with a concentration of 8mg / ml: mix 10ml of 8mg / ml graphene oxide aqueous solution with 10ml The 1-ethyl-3-methylimidazolium tetrafluoroborate was mixed uniformly by ultrasonic method, and then the mixed solution was placed in a vacuum oven at 35°C for 3 days to remove moisture.

[0046] (2) Activation of carbon fiber: the carbon fiber was ultrasonically cleaned 3 times with ethanol and water, and then dried. The carbon fiber was used as the working electrode, the platinum mesh electrode was used as the auxiliary electrode, and the saturated calomel electrode was used as the reference electrode. 2 SO 4 with HNO 3 In a mixed acid with a volume ratio of 1:1, under the condition of a constant potential of +3V, electrocatalytic oxidation was carried out for 10 minutes, and then soaked and washed with deionized water u...

Embodiment 3

[0051] Include the following steps:

[0052] (1) select ionic liquid 1-butyl-3-methylimidazole trifluoromethanesulfonate for use, prepare the graphene oxide-ionic liquid dispersion liquid that concentration is 3mg / ml: the graphene oxide aqueous solution of 5ml 3mg / ml is mixed with 10ml of 1-butyl-3-methylimidazolium trifluoromethanesulfonate was mixed uniformly by ultrasonic method, and then the mixture was placed in a vacuum oven at 35°C for 3 days to remove the water.

[0053] (2) Activation of carbon fiber: the carbon fiber was ultrasonically cleaned 3 times with ethanol and water, and then dried. The carbon fiber was used as the working electrode, the platinum mesh electrode was used as the auxiliary electrode, and the saturated calomel electrode was used as the reference electrode. 2 SO 4 with HNO 3 In a mixed acid with a volume ratio of 1:1, under the condition of a constant potential of +3V, electrocatalytic oxidation was carried out for 10 minutes, and then soaked an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com