Crankshaft crank throw curved forging mould for large ship and designing method of preformed blank

A design method and pre-forming technology, applied in the field of forging, can solve the problems of high machining difficulty, uneven machining allowance, thinning of the side of the crank arm, etc., and achieve the effect of reducing the number of tests, research costs, and machining allowances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

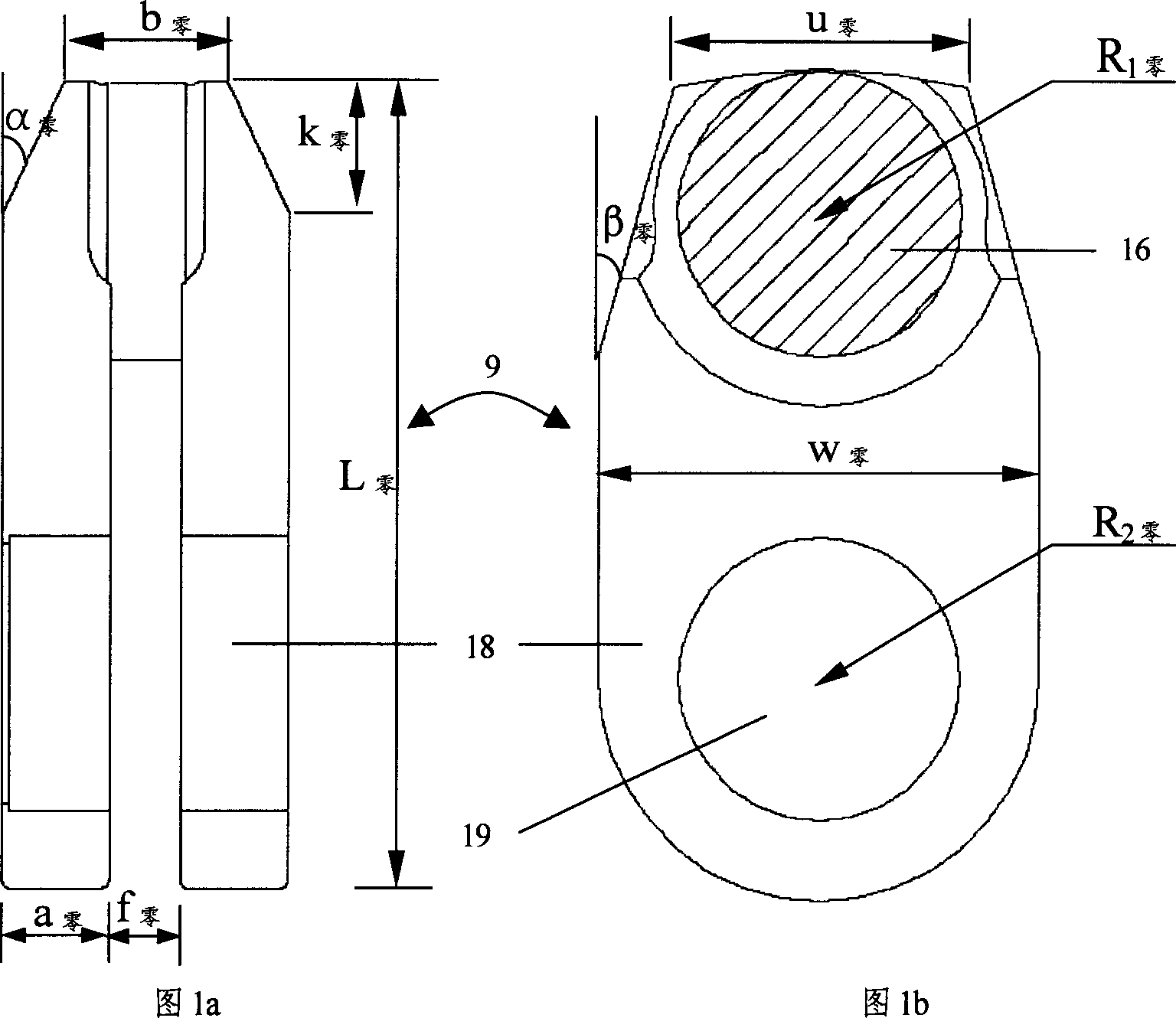

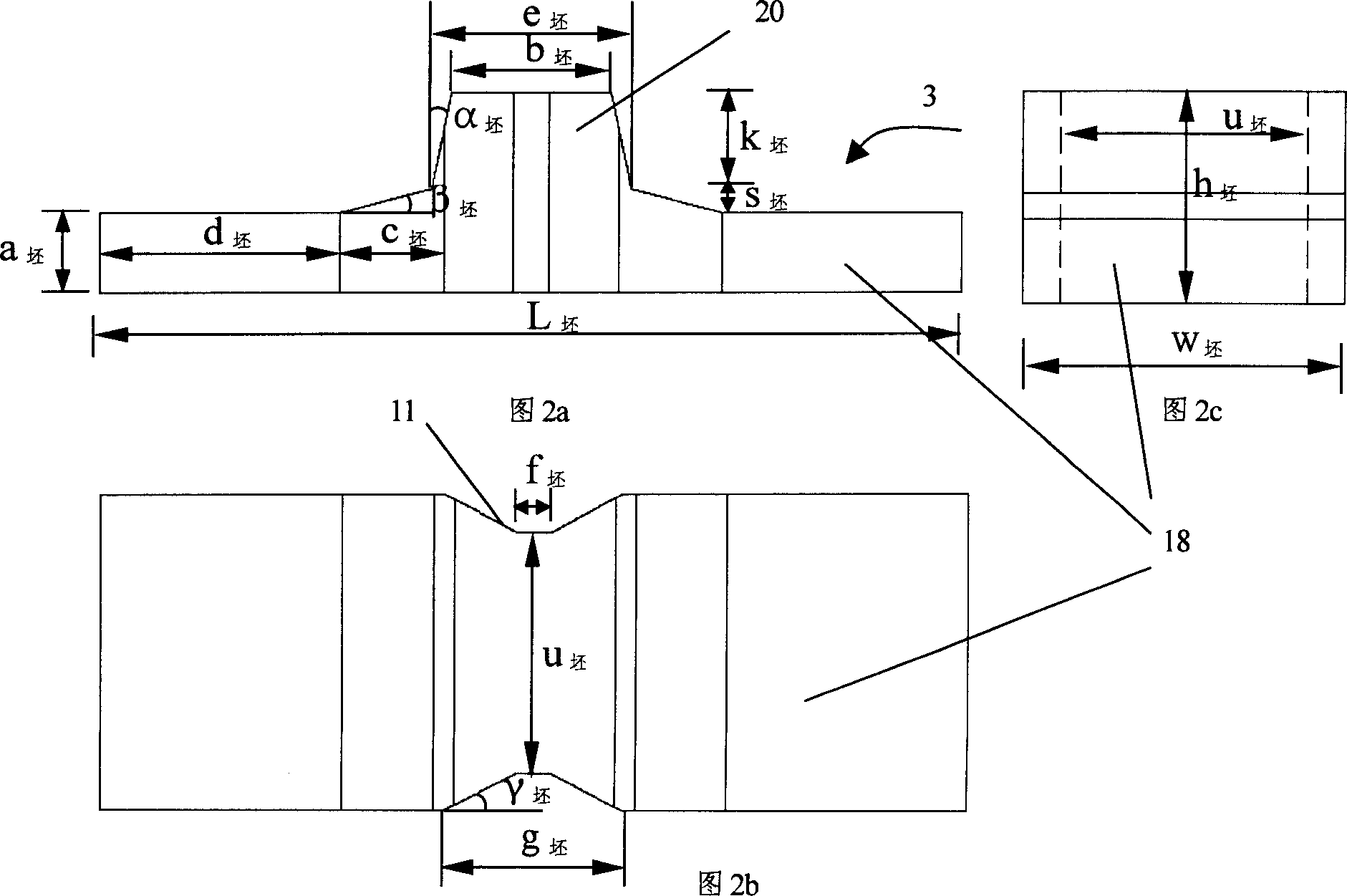

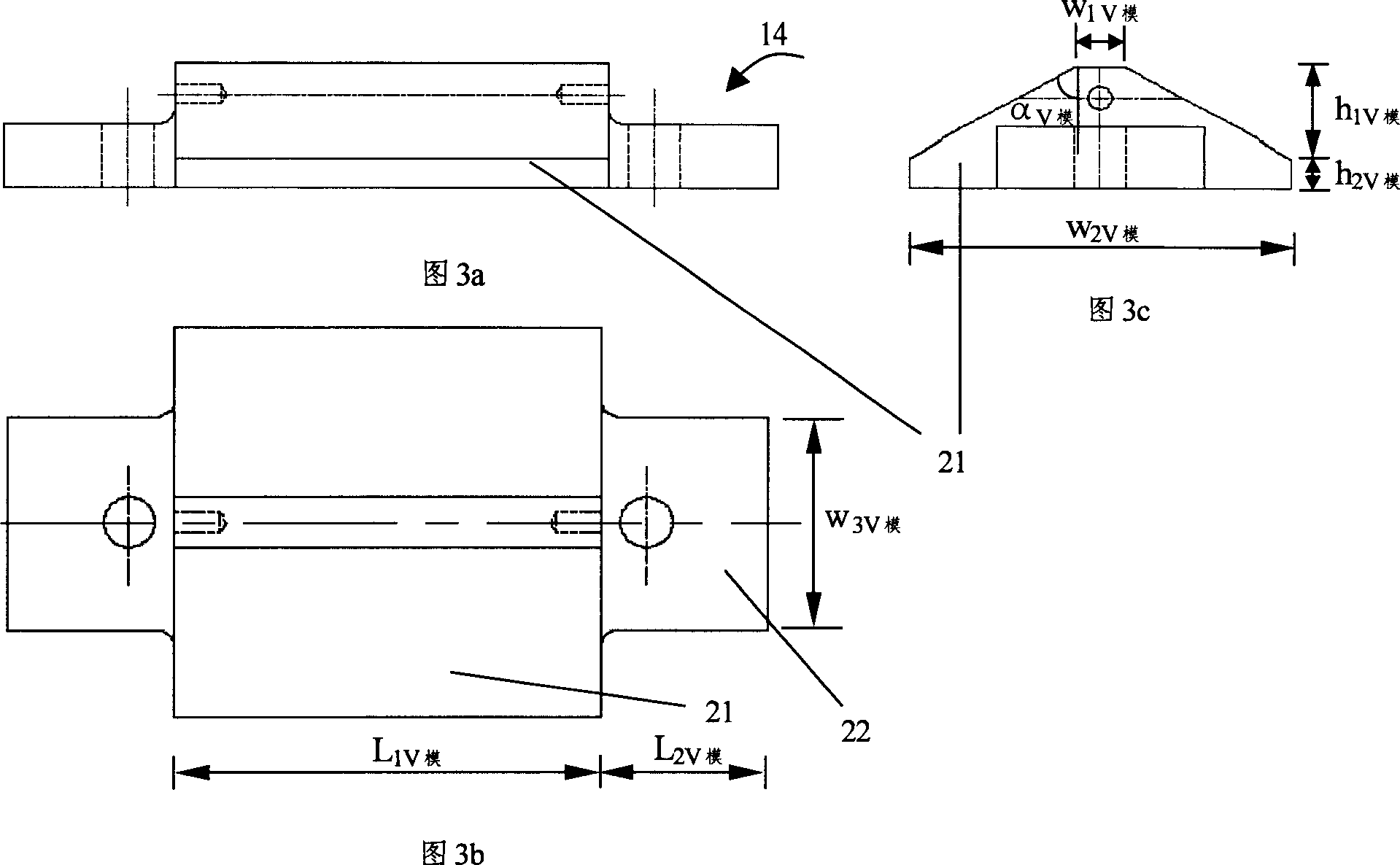

[0142] The forged part in this embodiment is the 6S60MC-C crankshaft throw of MAN B&W patent company. The material of the blank is S34MnV, the weight of the blank is 15t, the heating temperature of the blank is 1250°C, the material of the mold is 35CrMo, and the pressing speed of the upper anvil of the hydraulic press is about The computer simulation results of the forging process are shown in Figure 9-13. It can be known from the computer simulation results that during the bending process, the arc-shaped gap at the lower end of the upper die is just stuck in the middle of the blank, which can limit the material in the middle of the blank to bulge to both sides. When the upper die contacts the lower die, the bending stops. At this time, the bending The middle part of the turning blank is cylindrical, which is consistent with the shape of the processed part (see Figure 12-13). This not only reduces the machining allowance, but also greatly reduces the difficulty of cold working....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com