Method for extracting indium and recovering valuable metals from flue dust of tin

A valuable metal, smoke and dust technology, applied in the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of tin system production hazards, many impurity elements, low grades, etc., to improve the comprehensive recycling rate of resources, advanced technology , the effect of short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

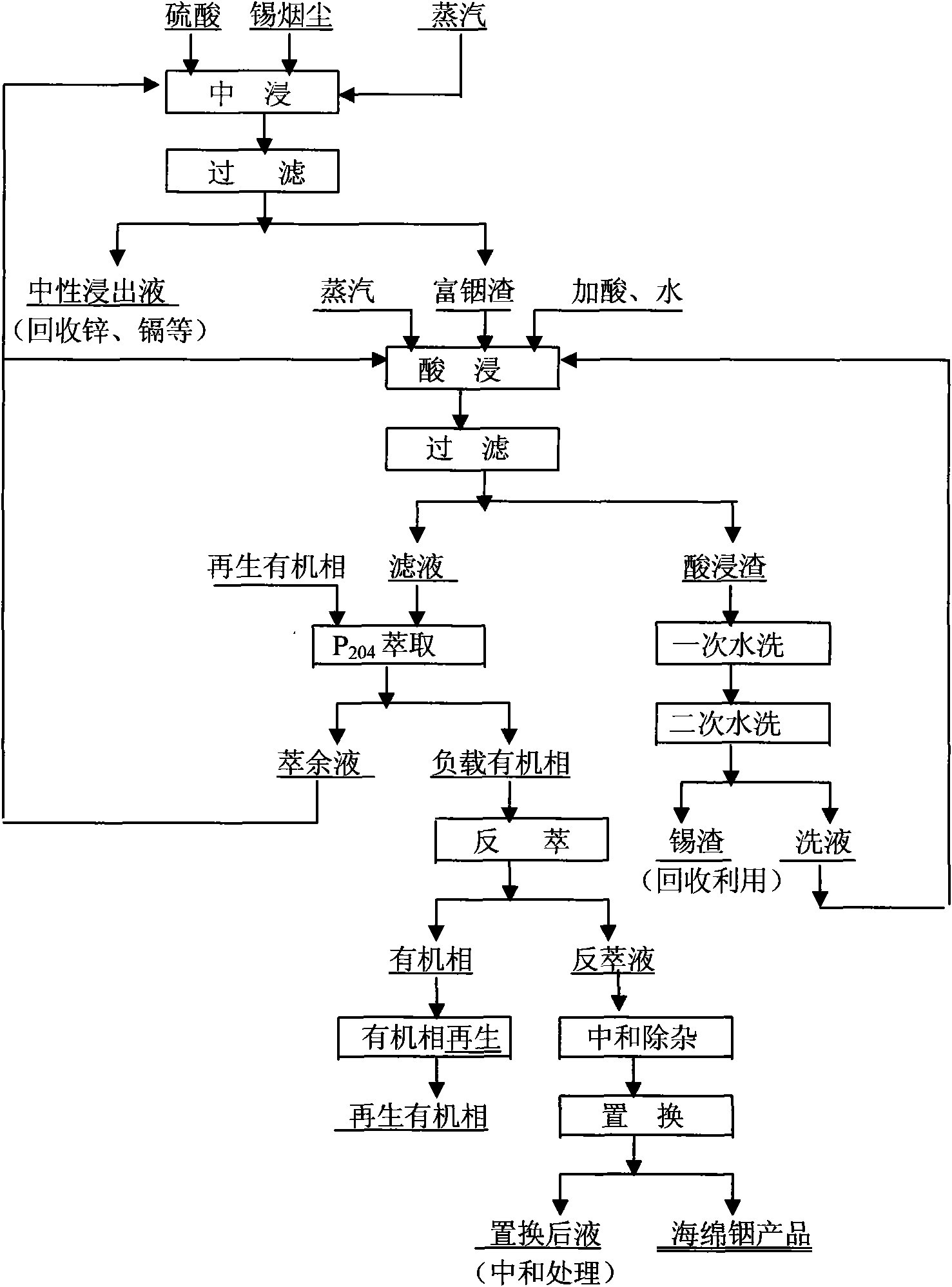

Method used

Image

Examples

Embodiment 1

[0022] The composition is (%) Sn53.25, Pb4.25, As6.25, Fe1.05, Cu0.019, Zn5.61, In0.137, Cd5.16, Bi0.232, S0.598 Ausmelt refining A total of 18.55 tons of materials were put into the trial production of tin fumes, and 18.77kg of sponge indium products were produced, which contained 92.70% of indium, and the direct yield of indium was 68.46%.

[0023] (1) Intermediate leaching: Use the raffinate containing indium-tin fume to adjust the initial acid pH to 1, the liquid-solid ratio (V / W) = 4:1, and the normal temperature and leaching temperature to be 50°C to 60°C. Under stirring and leaching for 4 hours, control the final acid pH = 2-2.5. As, Cd, Zn and other impurity elements enter the leaching solution, with P 507 The zinc in the leaching solution is extracted, and the zinc recovery rate is 98%. Sn, Pb, In into leaching slag, indium-rich slag secondary acid leaching.

[0024] (2) Acid leaching: The indium-rich slag leached from (1) is stirred and leached for the second time...

Embodiment 2

[0030] The composition is (%) Sn26.27, Pb5.55, As5.34, Fe1.35, Cu0.069, Zn15.75, In0.415, Cd1.13, Bi0.191, S1.33 electric furnace tin smelting smoke, test A total of 19.60kg of material was input, and 65.36g of sponge indium product was produced, which contained 92.40% of indium, and the direct yield of indium was 74.24%.

[0031] (1) Intermediate leaching: the indium-containing tin fume is leached for 40 minutes at room temperature with the raffinate after extraction of indium to adjust the initial acid pH=2.5, the liquid-solid ratio (V / W)=7:1, and control the final acid pH= 3~4. Zn, As, Cd, Fe and other impurity elements enter the leaching solution, the leaching rate of Zn is more than 80%, and the leaching rate of As, Cd, Fe is more than 90%. with P 507 The zinc in the leaching solution is extracted, and the zinc recovery rate is 98%. Sn, Pb, In into leaching slag, indium-rich slag secondary acid leaching.

[0032] (2) Acid leaching: The indium-rich slag leached from (1...

Embodiment 3

[0038] The composition is (%) Sn51.63, Pb4.6, As5.62, Fe0.755, Cu0.0394, Zn5.82, In0.291, Cd4.98, Bi0.231, S0.935 tin fume, the test total 48.0kg of material was input, and 115.78g of sponge indium product was produced. The product contained 90.15% of indium, and the direct yield of indium was 74.72%.

[0039] (1) Intermediate leaching: use the indium-containing tin fume to adjust the initial acid pH to 1.5 with the raffinate after indium extraction, the liquid-solid ratio (V / W) = 5:1, and stir at the leaching temperature of 50°C to 60°C Leach for 3 hours, and control the final acid pH=2.5. The leaching rates of As, Cd and Zn are all greater than 85%. 507 The zinc in the leaching solution is extracted, and the zinc recovery rate is 98%. Sn, Pb, In into leaching slag, indium-rich slag secondary acid leaching.

[0040] (2) Acid leaching: The indium-rich slag leached from (1) is stirred and leached for the second time, the initial concentration of the sulfuric acid solution is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com