Treatment method of acid heavy metal wastewater

A treatment method and technology for heavy metals, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of technological progress, qualified water quality and high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Treatment pH=2.03, Cu 2+ =120mg / L, F - =3mg / L, Fe 3+ =1800mg / L metallurgical pickling wastewater;

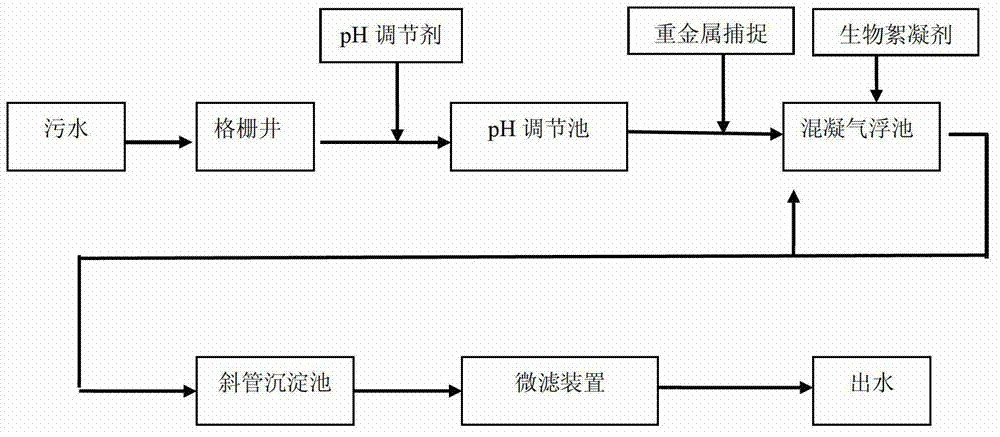

[0026] take (with figure 1 ) Process of acidic heavy metal wastewater—pH adjustment tank—coagulation air flotation device—inclined plate settlement—continuous microfiltration device—effluent reuse;

[0027] The waste water passes through the grid well to remove large floating objects and mechanical impurities and enters the pH adjustment pool. The pH adjustment pool has a reserve of 150 cubic meters. It uses mechanical stirring to adjust the water quality and volume, and adjust the pH. The sewage uses liquid sodium hydroxide to control the pH. 8.5;

[0028] Before entering the coagulation air flotation tank, use a pipe mixer to add 25 mg / L of heavy metal capture agent; the air flotation tank adopts a vortex concave air flotation device, and add polysaccharide bioflocculant 2 mg / L to the air flotation tank, heavy metal ions, organic matter, suspended matter, etc. Form...

Embodiment 2

[0033] Treatment pH=1.68, SS=2579mg / L, Cu 2+ =500mg / L, Ni + =35mg / L, processing capacity=150m 3 / d smelting pickling wastewater;

[0034] a. Grille pH adjustment: Sewage passes through the grid well to remove large impurities and enters the pH adjustment tank. The alkali device automatically adds milk of lime or quicklime or sodium hydroxide or carbide slag to adjust the pH to 8;

[0035] b. Coagulation and air flotation treatment: add 40mg / L of heavy metal scavenger before the coagulation and air flotation tank, and add 2mg / L of biological flocculant before the air flotation tank; through vortex air flotation, remove organic matter, heavy metals and suspended solids;

[0036] c. Depth pretreatment: the air flotation effluent is settled by the inclined plate, and enters the continuous microfiltration device for filtration to remove suspended solids and colloids;

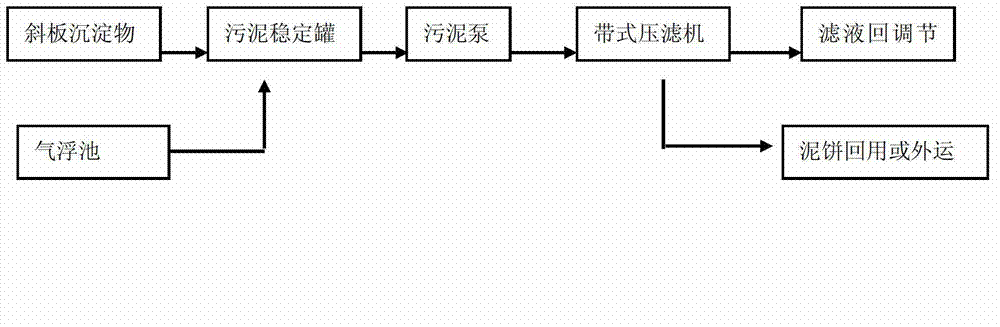

[0037] d. Disposal of sludge and scum: Concentrate the air scum through the sludge in the scum tank and the sed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com