Numerical control groove broaching equipment for customized furniture board processing

A sheet metal processing and grooving technology, applied in wood processing appliances, manufacturing tools, multi-purpose machinery, etc., can solve the problems of low sheet processing accuracy, uncontrollable operating errors, low processing efficiency, etc., to reduce production occupied area, reliable High performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

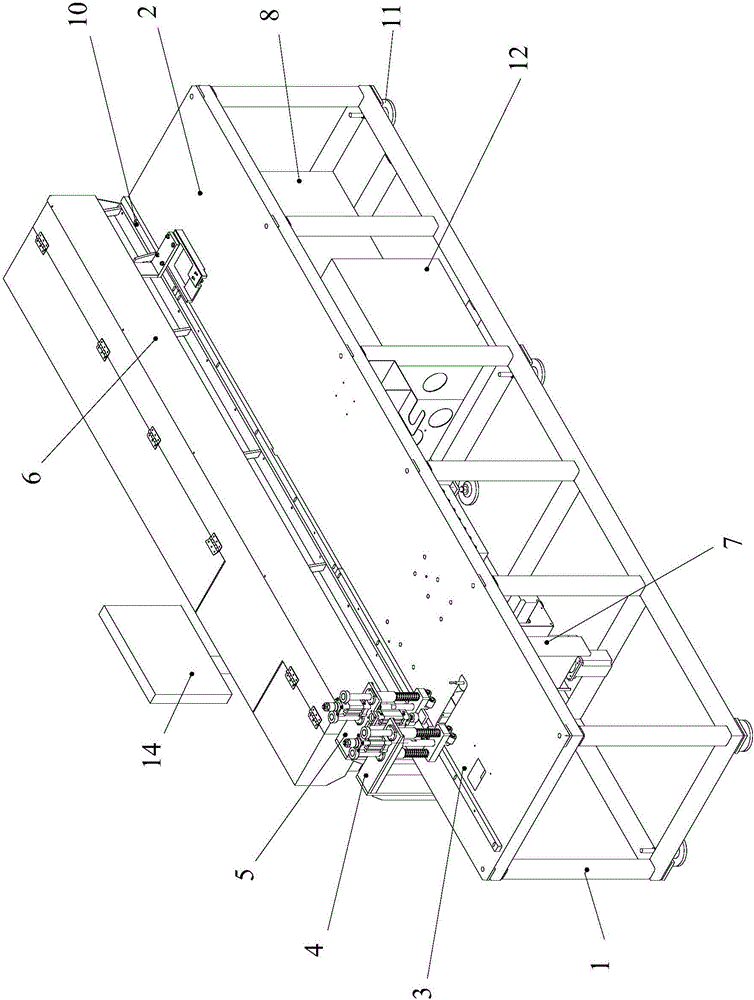

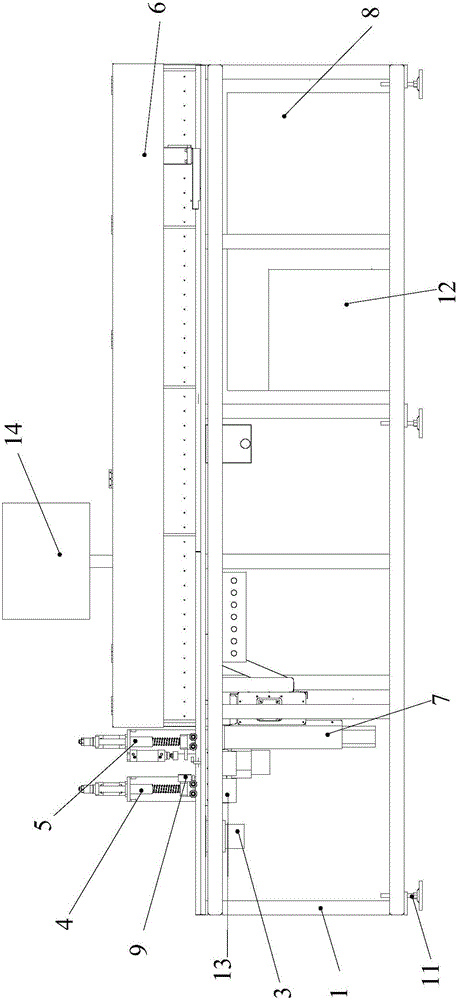

[0054] like Figure 1 to Figure 9 As shown, the present invention is used for the numerical control slotting equipment of customized furniture plate processing, and it comprises:

[0055] a rack 1 provided with a platform 2;

[0056] A scanning device 12 for scanning plate labels;

[0057] Measuring device 9 for measuring the actual size of the plate;

[0058] An electric spindle processing device 7 for adjusting the initial position of groove processing according to the groove position of the plate and performing groove processing;

[0059] An x-axis pushing plate device 6 for positioning the plate and pushing the plate for slotting;

[0060] The front pressing device 5 used for pressing and fixing the plate during processing;

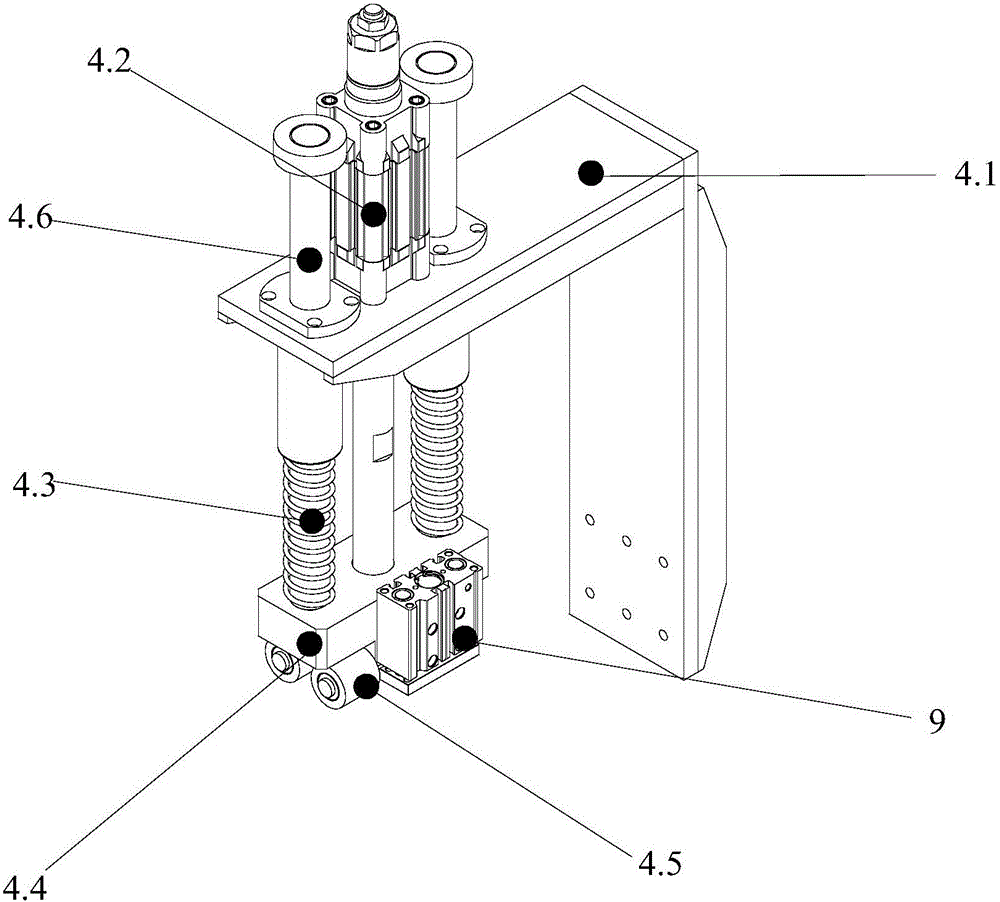

[0061] The rear pressing device 4 used for pressing the plate during processing;

[0062] Dust suction device for cleaning up processing waste;

[0063] and control devices;

[0064] Wherein, a plurality of foot cups 11 are arranged under the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com