Automatic plate machining device for customizing furniture

An automatic processing and board technology, which is applied to wood processing equipment, manufacturing tools, bark area/debris/dust/waste removal, etc., can solve the problems of low production efficiency and low degree of automation, so as to improve production efficiency and improve Accuracy and quality, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] In this embodiment, the automatic 5-side processing of the plate by the plate automatic processing equipment is taken as an example to describe the following.

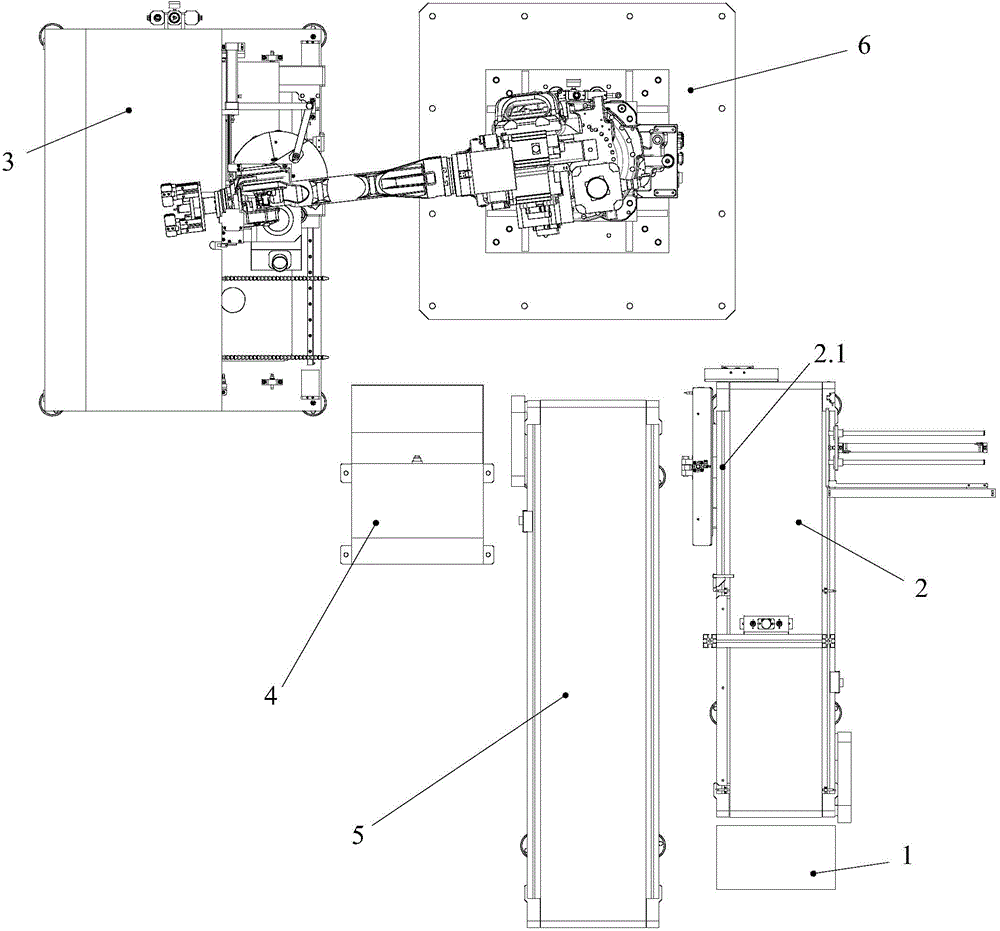

[0057] Such as Figures 1 to 10 As shown, the plate automatic processing equipment for customized furniture of the present invention is used to automatically realize 5-side processing of plates, and the processing equipment includes:

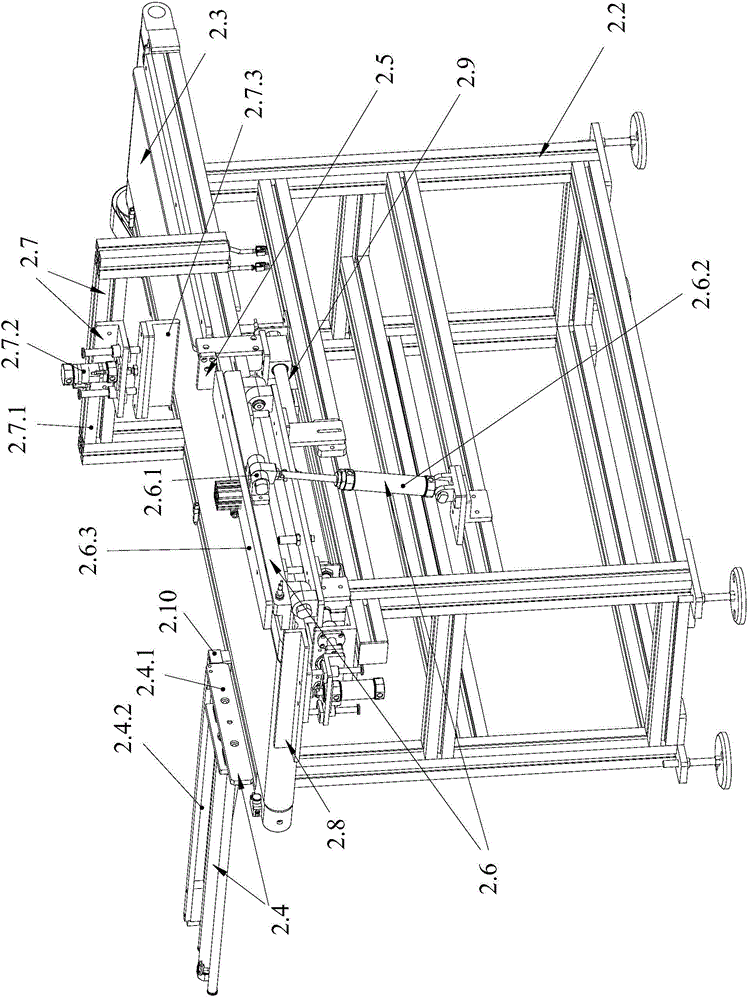

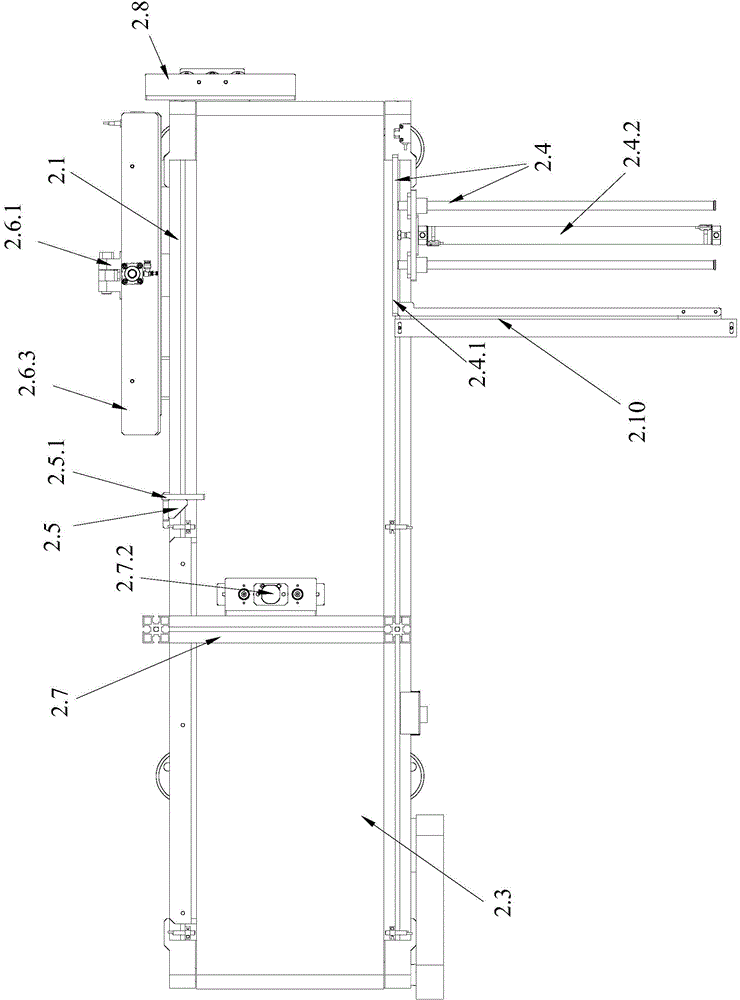

[0058] A feed conveying mechanism 2 for separating, adjusting and measuring the plates to the feed port 2.1, and flipping the plates at the feed port 2.1;

[0059] The scanning mechanism 1 is used to read the information of the plate label on the feeding conveying mechanism 2; the scanning mechanism 1 can be docked with the end of the feeding conveying mechanism 2 away from the feed port 2.1; or the scanning mechanism can be installed on the feeding conveying mechanism 2 on;

[0060] Main processing mechanism 3 for front and back processing of plates;

[0061] A side processing...

Embodiment 2

[0085] The only difference between this embodiment and Embodiment 1 is that according to the production requirements, the automatic processing equipment for customized furniture in this embodiment can realize automatic processing of 1, 2, 3 or 4 sides of the board in one processing process. Other structures are consistent with Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com