Plate punching device for furniture manufacturing

A technology of punching device and plate, applied in fixed drilling machine and other directions, can solve the problems of high labor intensity, reduce punching efficiency, easy arm soreness, etc., and achieve the effect of reducing labor intensity and improving punching efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

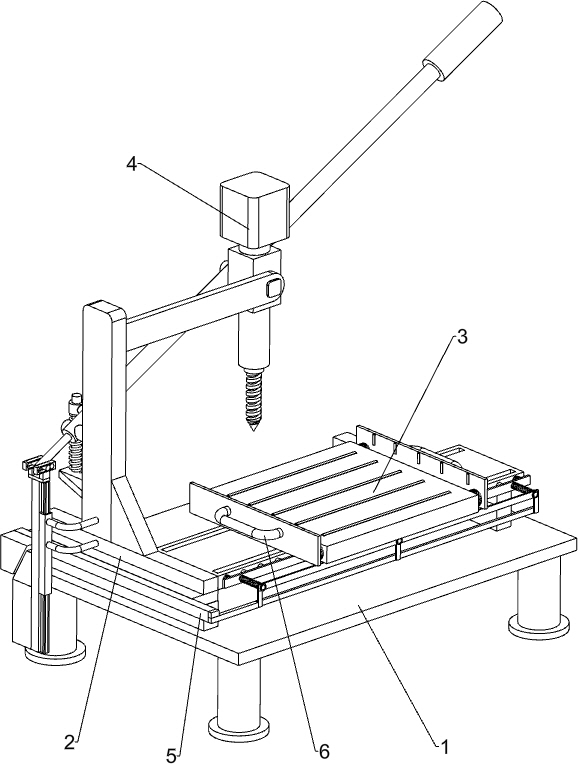

[0022] A kind of board punching device for making furniture, such as Figure 1-5 As shown, it includes a base plate base 1, a mounting frame 2, a plate moving mechanism 3 and a punching mechanism 4, and the left side of the top of the base plate base 1 is connected with a mounting frame 2, and the base plate base 1 is equipped with a plate moving mechanism 3. On the mounting frame 2 A punching mechanism 4 is installed.

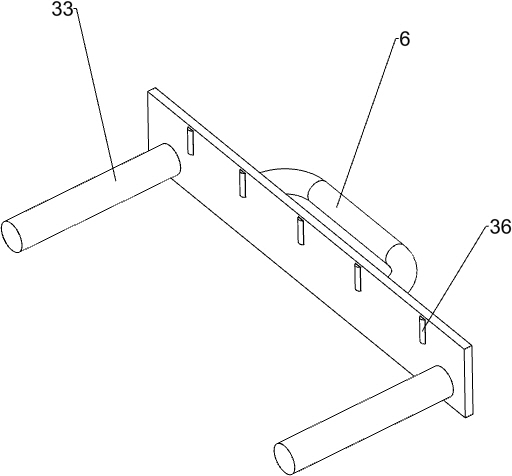

[0023] The plate moving mechanism 3 includes a grooved guide rail plate 31, a sliding pallet 32, a sliding side plate 33, a first back-moving spring 34, a first sliding shaft 35 and a second sliding shaft 36, and the right side of the top of the base seat 1 and the mounting frame 2. A slotted guide rail plate 31 is connected between the sides, and a sliding supporting plate 32 is slidably connected on the slotted guiding rail plate 31. The left and right sides of the sliding supporting plate 32 are all slidingly connected with a sliding side plate 33, and the ...

Embodiment 2

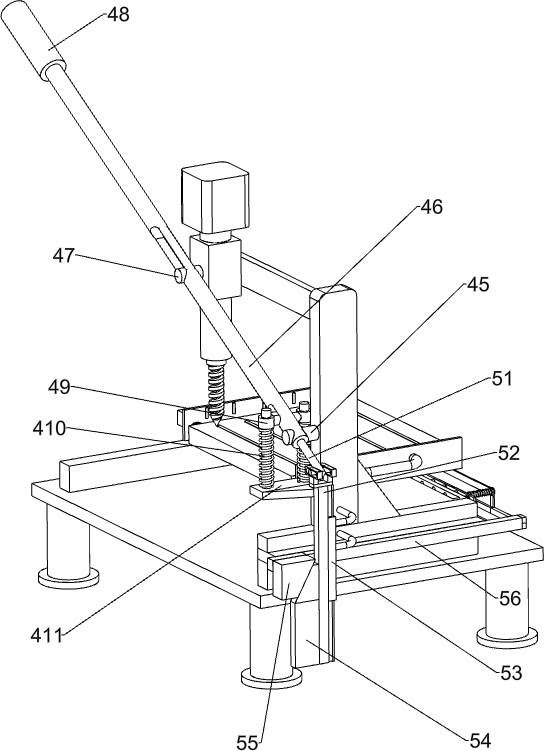

[0027] On the basis of Example 1, such as Figure 1-3 and Figure 5 As shown, a lateral movement locking mechanism 5 is also included, and the lateral movement locking mechanism 5 includes a T-shaped bar 51, a sliding frame 52, a fixed limit guide rail 53, a first wedge block 54, a second wedge block 55, and a sliding connection frame 56 , the second fixed guide rail plate 57, the sliding coupling frame 58, the fixed guide rod 59, the clamping frame 510, the third return spring 511 and the fourth return spring 512, the left side of the installation frame 2 is connected with a fixed limit guide rail 53, fixed The limit guide rail 53 is slidably connected with a sliding frame 52, and the upper part of the sliding frame 52 is slidably connected with a T-shaped bar 51. Block 54, the mounting frame 2 is embedded with a second fixed guide rail plate 57, the second fixed guide rail plate 57 is slidably connected with a sliding connection frame 56, and the rear side of the sliding co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com