Automatic wood cutting machine

A cutting machine and automatic technology, applied in the field of furniture manufacturing, can solve the problems of low processing efficiency, high risk, slipping, etc., and achieve the effect of good clamping effect, strong safety and accurate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

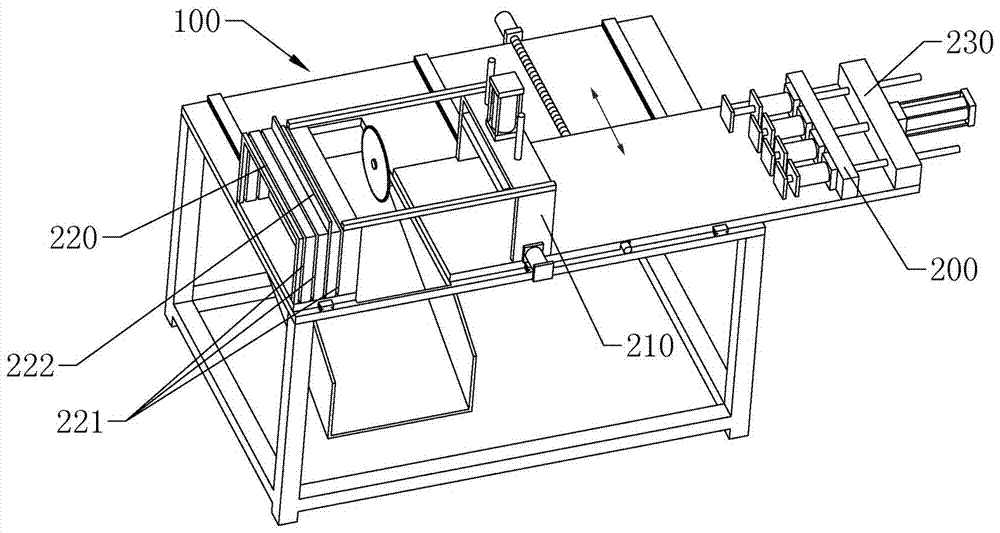

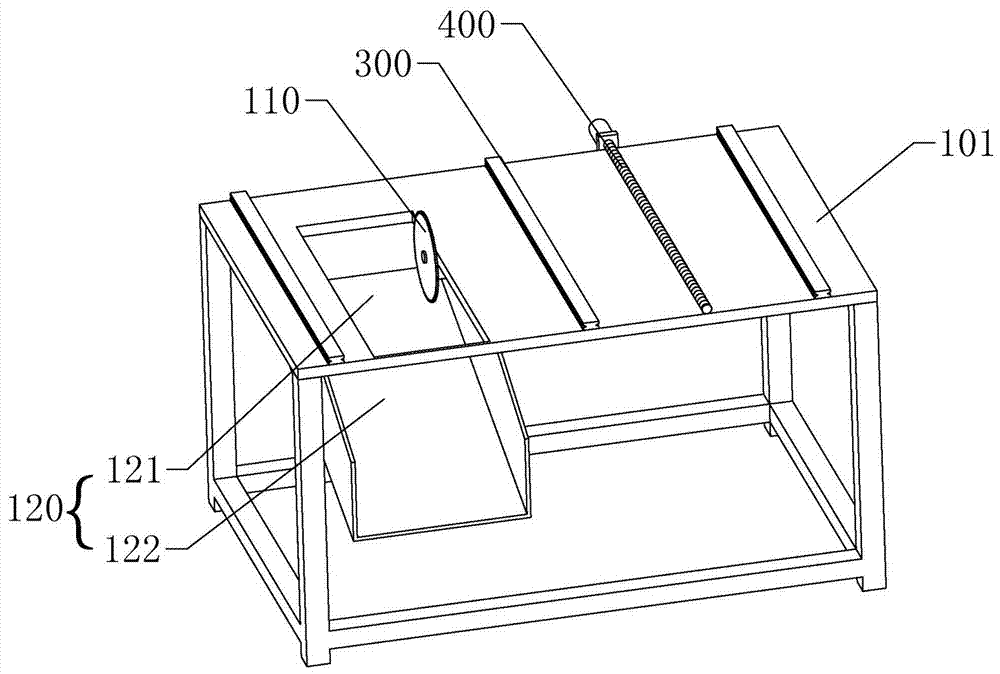

[0033] according to Figure 1~4 As shown in the figure, an automatic wood cutting machine includes: a fixed frame 100 and a movable frame 200, the movable frame 200 is arranged above the fixed frame 100, and a guide rail 300 and a screw mandrel 400 are arranged between the fixed frame 100 and the movable frame 200;

[0034] Fixture 100 comprises, top plate 101, cutting mechanism 110 and discharge mechanism 120, and discharge mechanism 120 comprises the blanking outlet 121 that is located on top plate 101 and blanking slide 122, and cutting mechanism 110 is the cutting machine that is fixed on top plate 101 below , and the slice top of the cutting machine is higher than the top of the top plate 101;

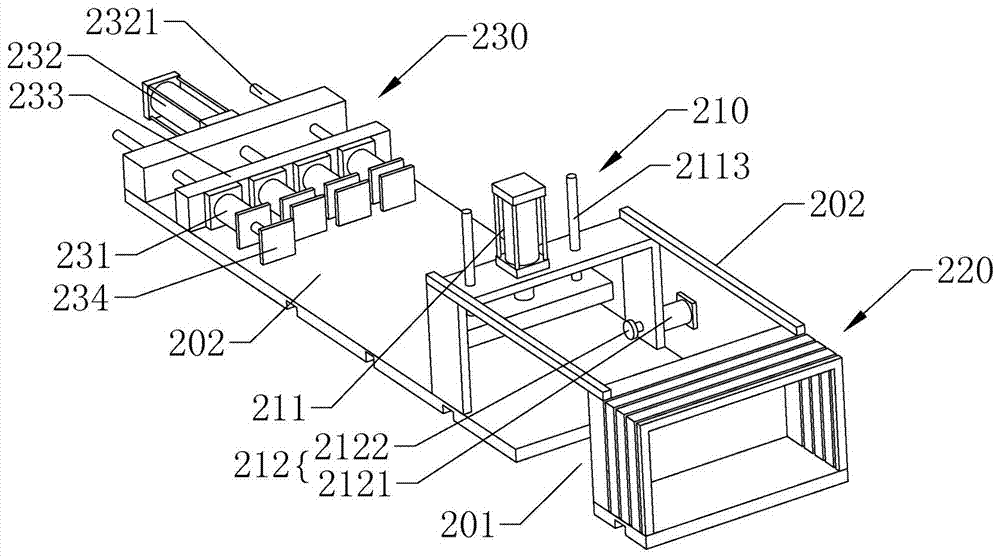

[0035] The movable frame 200 includes a cutting area 201, a clamping mechanism 210, a length positioning mechanism 220 and a pushing mechanism 230 positioned above the blanking outlet 121, the clamping mechanism 210, the length positioning mechanism 220 and the pushing mechanism 2...

Embodiment 2

[0041] The difference from the above-mentioned embodiment 1 is that, according to Figure 6 As shown, the movable frame 200 is provided with a top alignment mechanism 240 , and the top alignment mechanism 240 includes a pole 241 disposed on the side of the slide plate 203 close to the cutting area 201 and a baffle 242 hinged on the pole 241 . The pole 241 is provided with a shelf 2411 for preventing the baffle 242 , and the baffle 242 is provided with a bayonet 2421 away from the hinge, which is used for fixing the baffle 242 on the connecting rod 202 after it is lifted.

[0042] The unloading slide 122 includes a finished product passage 1221 and a waste passage 1222 , and the waste passage 1222 is located on a side of the unloading slide 122 close to the clamping mechanism 210 .

[0043]When this embodiment is in use, the difference from Embodiment 1 is that in the process of flushing the head, the wood is pushed against the baffle plate 242, and then the whole movable frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com