Colored polyvinyl chloride foamed sheet and preparation method thereof

A technology of polyvinyl chloride and foamed sheet, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of fading, rising surface temperature of foamed sheet, deformation of foamed sheet, etc., and achieve cost saving , Reduce product density, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The polyvinyl chloride colored foam board described in this embodiment consists of a core layer, an upper skin layer and a lower skin layer,

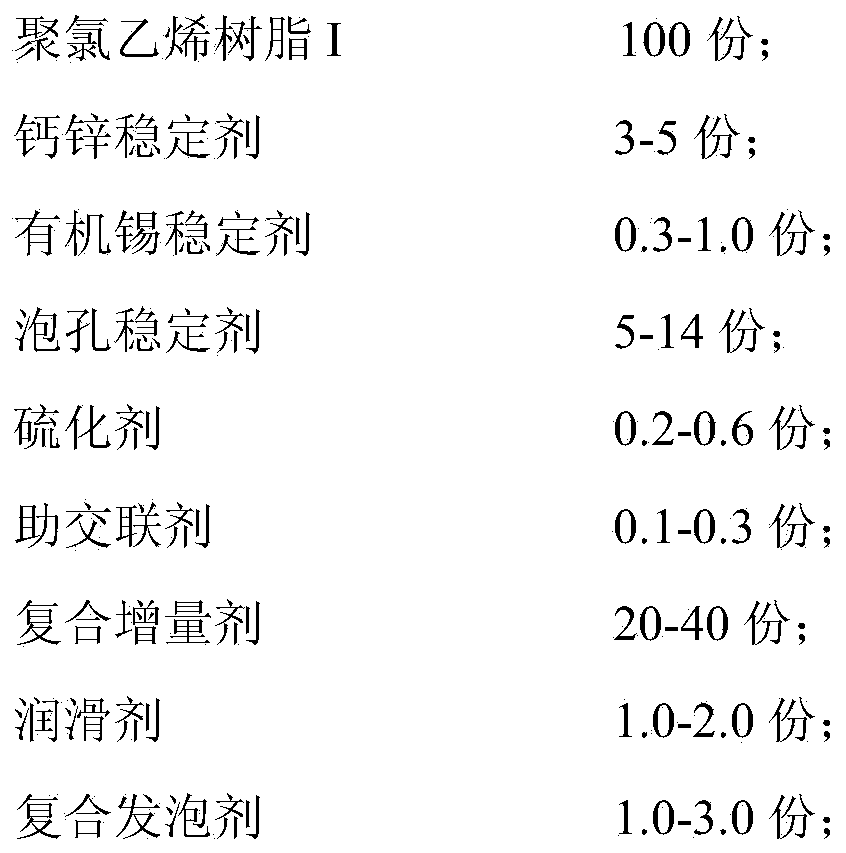

[0042] Wherein, the core layer is made of the following raw materials in parts by weight:

[0043]

[0044]

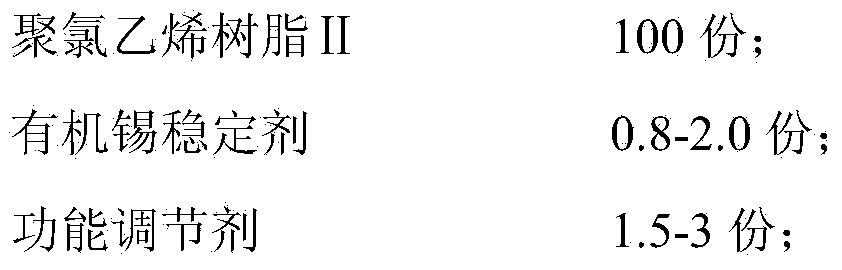

[0045] The upper epidermal layer and the lower epidermal layer have the same raw materials, and are made of the following raw materials in parts by weight:

[0046]

[0047] The mass ratio of the upper skin layer to the lower skin layer ingredients is 1:1;

[0048] The mass ratio of the core layer to the skin layer ingredients is 11.8:0.2.

[0049] The preparation method is:

[0050] (1) Add the core material of the formula into the high-speed mixer, heat it to 105°C, then put it into the cold mixer, put it into the storage bin when it is cooled to 40-50°C, and automatically load it with a vacuum feeder The material is fed to the conical twin-screw extruder for plasticizing processing. Among them, the screw t...

Embodiment 2

[0054] The polyvinyl chloride colored foam board described in this embodiment consists of a core layer, an upper skin layer and a lower skin layer,

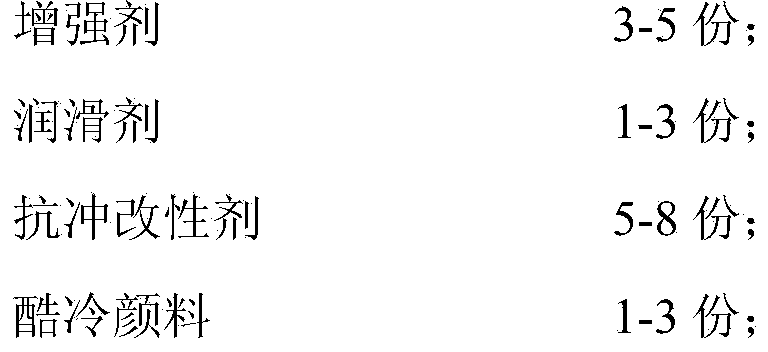

[0055] Wherein, the core layer is made of the following raw materials in parts by weight:

[0056]

[0057] The raw materials of the upper epidermis and the lower epidermis are the same, and are made of the following raw materials in parts by weight:

[0058]

[0059] The mass ratio of the upper skin layer to the lower skin layer ingredients is 1.1:1;

[0060] The mass ratio of the core layer to the skin layer ingredients is 19.6:0.4.

[0061] The preparation method is:

[0062] (1) Add the core layer raw materials of the formulated amount into the high-speed mixer, heat to 110°C, then put them into the cold mixer, put them into the storage bin when cooled to 50°C, and use the vacuum feeder to automatically feed the material, Feed to the conical twin-screw extruder for plasticizing. Among them, the screw temperature is 10...

Embodiment 3

[0066] The polyvinyl chloride colored foam board described in this embodiment consists of a core layer, an upper skin layer and a lower skin layer,

[0067] Wherein, the core layer is made of the following raw materials in parts by weight:

[0068]

[0069] The upper epidermal layer and the lower epidermal layer have the same raw materials, and are made of the following raw materials in parts by weight:

[0070]

[0071] The mass ratio of upper skin layer and lower skin layer ingredients is 1:2;

[0072] The mass ratio of the core layer to the skin layer ingredients is 25.4:0.6.

[0073] The preparation method is:

[0074] (1) Add the core layer raw materials of the formulated amount into the high-speed mixer, heat to 110°C, then put them into the cold mixer, put them into the storage bin when cooled to 45°C, and use the vacuum feeder to automatically feed the material, Feed to the conical twin-screw extruder for plasticizing. Among them, the screw temperature is 90°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com