Shaped wooden mould pressing furniture part and manufacturing method thereof

A technology of furniture parts and manufacturing methods, which is applied in the field of manufacturing special-shaped wood molded furniture parts and special-shaped wood molded furniture parts, can solve the problems of high processing cost and long time consumption of solid wood furniture parts, and achieve reduction of raw material costs and labor costs, processing Good performance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

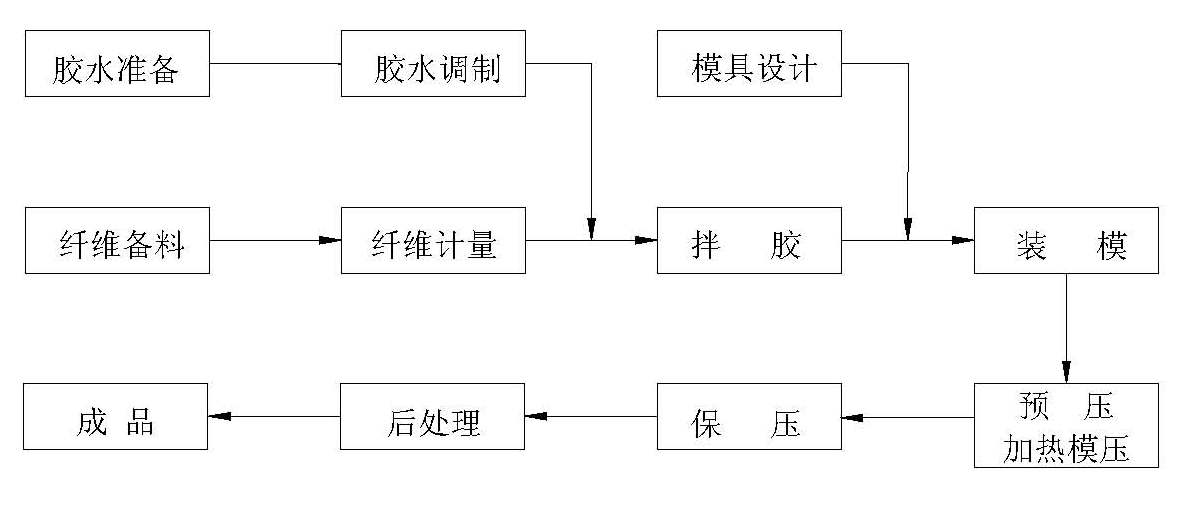

[0032] Embodiment 1-2: a kind of special-shaped wooden molded furniture part, its manufacture method is as follows:

[0033] ① Pretreatment of raw materials, weighing various raw materials according to the ratio shown in Table 1, dry wood materials in advance, and control the moisture content of wood materials at 6-14% according to the temperature and humidity of the manufacturing environment; If it is too low, the heating effect of the workpiece will be unsatisfactory. On the contrary, if it is too high, it cannot ensure that the excess water can be volatilized in the form of water vapor during the heating process, resulting in bubbling and delamination of molded furniture parts.

[0034] ② Glue adjustment, in order to make the adhesive meet the requirements of use, it needs to be adjusted. Mix the adhesive, curing agent and waterproofing agent, and mix well with a mixer.

[0035] ③ Glue sizing, put the dried wood material and the prepared glue into the glue mixer and mix ev...

Embodiment 3-4

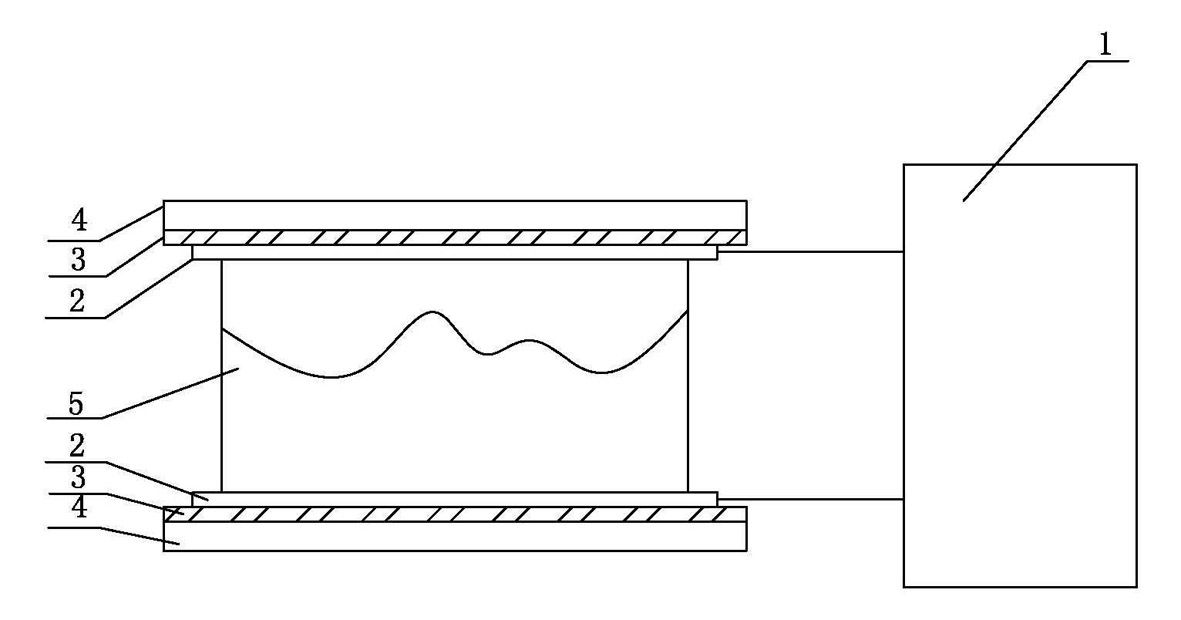

[0041] The specific scheme is the same as in Example 1, except that in step 4., after the last feed is finished, pressurization is carried out slowly, and the pressure rises to 5MPa. Then turn on the high-frequency generator to make contact heating and high-frequency electric field heating proceed at the same time. An insulating and heat-conducting layer is provided between the high-frequency plate and the hot pressing plate. The temperature of the platen is controlled at 110°C, the heating time is set for 3 minutes, and the pressure is maintained for 5 minutes.

Embodiment 5-6

[0043] The specific scheme is the same as in Example 1, except that in step 4., after the last feed is finished, pressurization is carried out slowly, and the pressure rises to 4MPa. Then turn on the high-frequency generator to make contact heating and high-frequency electric field heating proceed simultaneously. There is an insulating and heat-conducting layer between the high-frequency plate and the hot pressing plate. Adjust the high-frequency generator positive current to 2.5A, grid current to 0.5A, and heat The temperature of the platen is controlled at 95°C, the heating time is set for 5 minutes, and the pressure is maintained for 12 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com