Degradable material, application thereof for preparing hollow container and preparation method and device of hollow container

A degradable material, hollow technology, applied in the field of degradable materials, can solve the problems of acid resistance, alkali resistance, corrosion resistance, anti-pollution performance is not good enough, unsuitable for corrosion resistance hollow containers, polyolefin resin is not easy to degrade, etc., to achieve strong promotion Non-toxicity, anti-pollution use requirements, easy processing and molding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

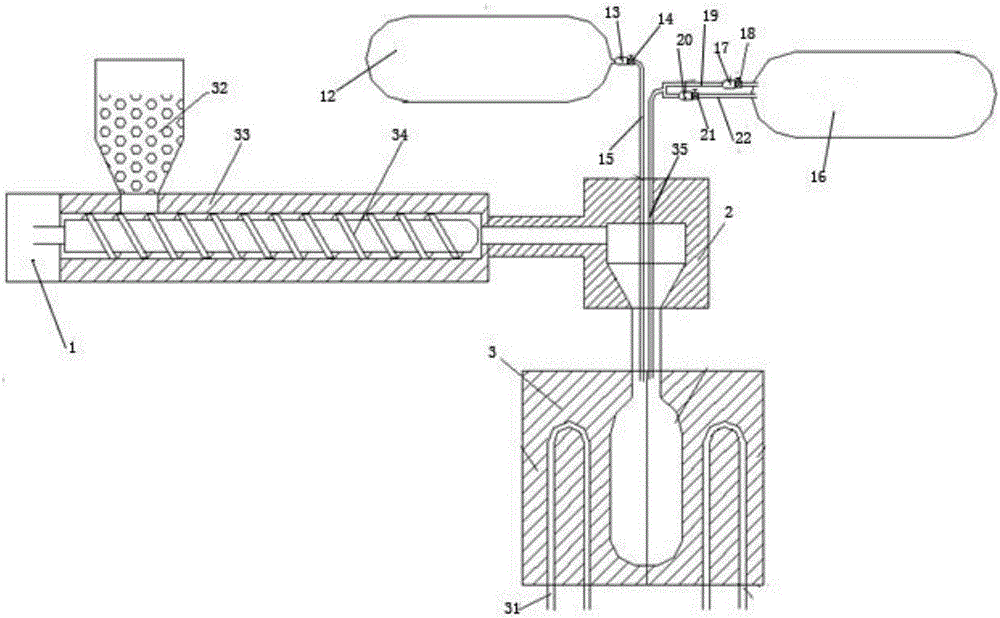

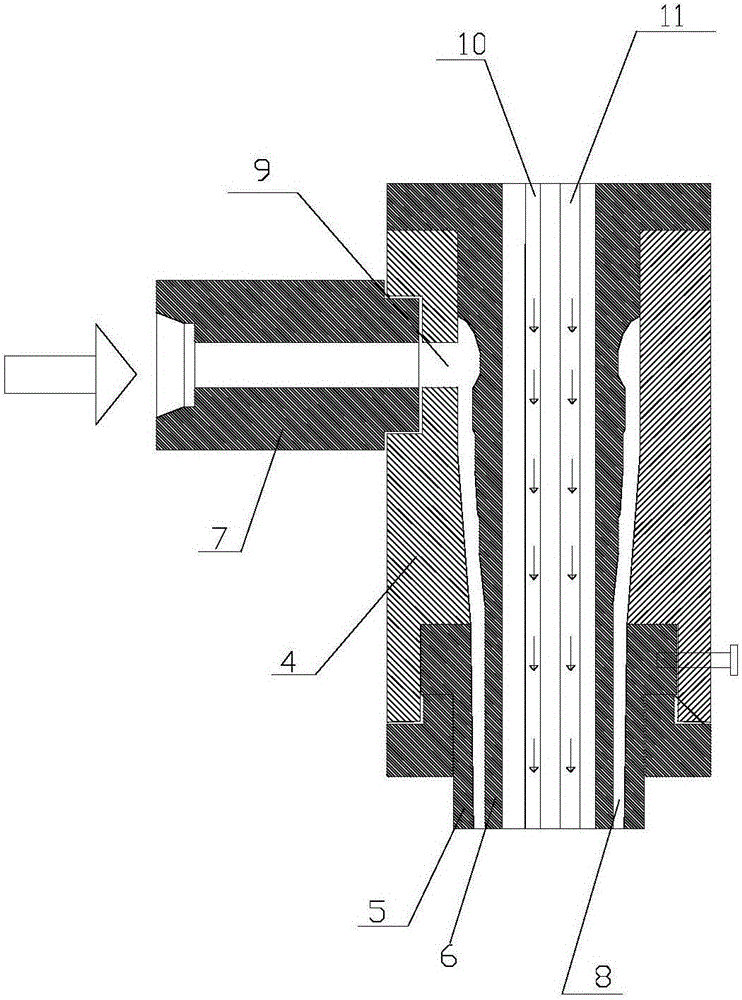

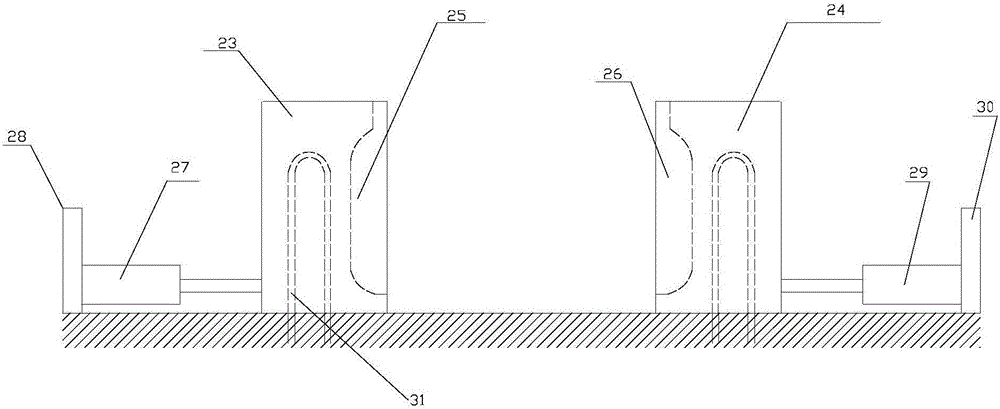

[0026] A method for preparing a compostable biodegradable hollow container, which comprises the following process steps:

[0027] (1) Material configuration: In terms of weight ratio, 100 parts of tapioca modified starch, 120 parts of polybutylene succinate, 30 parts of polybutylene terephthalate-adipate, 15 parts of glycerin, silane Put 0.1 part of joint agent, 5 parts of ethylene ethyl acrylate, and 5 parts of glyceryl monostearate into a high-low speed mixer and mix until uniform. The mixing temperature is 120°C, the mixing time is 30 minutes, and the stirring speed is 800 rpm ;

[0028] (2) Granulation: Send the materials configured in step (1) into the 75-type large-length-diameter ratio and high-vacuum twin-screw extruder Kneading, plasticizing, cross-linking and high-vacuum removal of water in the screw extrusion granulator to make special pellets for hollow molding. The granulation process conditions of the twin-screw extrusion granulator are: one set of 140°C , two ...

Embodiment 2

[0031] A method for preparing a compostable biodegradable hollow container, which comprises the following process steps:

[0032] (1) Material configuration: in terms of weight ratio, 90 parts of modified potato starch, 150 parts of polybutylene succinate-co-butylene terephthalate, 20 parts of polylactic acid, 0.1 part of xylitol, Put 2 parts of aluminate coupling agent, 4 parts of ethylene acrylic acid copolymer, and 3 parts of monoglyceride succinate into a high-low speed mixer and mix until uniform. The mixing temperature is 120°C, the mixing time is 30 minutes, and the stirring speed is The speed is 1200 rpm to fully react the coupling agent with starch and various resins.

[0033] (2) Granulation: Send the materials configured in step (1) into the 75-type large-length-diameter ratio and high-vacuum twin-screw extruder The kneading, plasticizing, cross-linking and high-vacuum removal of water in the screw extrusion granulator are extruded to make hollow-molded special pel...

Embodiment 3

[0036] A method for preparing a compostable biodegradable hollow container, which comprises the following process steps:

[0037] (1) Material configuration: In terms of weight ratio, 100 parts of sweet potato modified starch, 120 parts of polybutylene succinate, 80 parts of polycaprolactone, 16 parts of sorbitol, 0.2 parts of titanate coupling agent, Put 8 parts of ethylene-vinyl acetate and 6 parts of glyceryl laurate into a high-low speed mixer and mix until uniform. The mixing temperature is 118°C, the mixing time is 33 minutes, and the stirring speed is 1000 rpm;

[0038] (2) Granulation: Send the materials configured in step (1) into the 75-type large-length-diameter ratio and high-vacuum twin-screw extruder Kneading, plasticizing, cross-linking and high-vacuum removal of water in the screw extrusion granulator to make special pellets for hollow molding. The granulation process conditions of the twin-screw extrusion granulator are: one set of 140°C , two groups at 145°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com