Method and Apparatus for Apparel Customization

a technology for apparel and pants, applied in the field of apparel, can solve the problems of not being able to find pants that fit, not being able to meet customers as well as merchants, and not being able to meet customers at the same time, and achieve the effect of cost-effective and rapid one-at-a-time apparel creation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

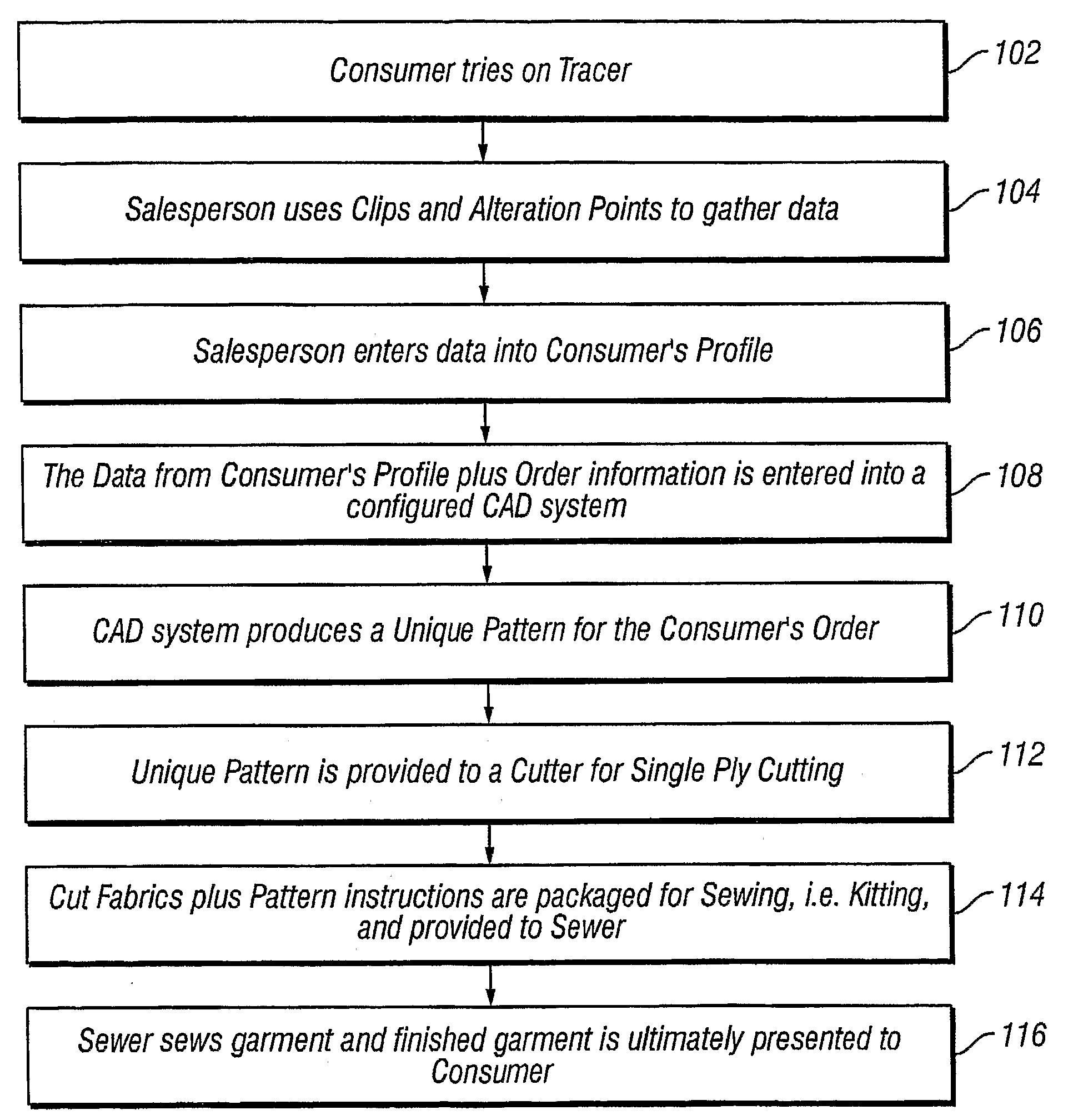

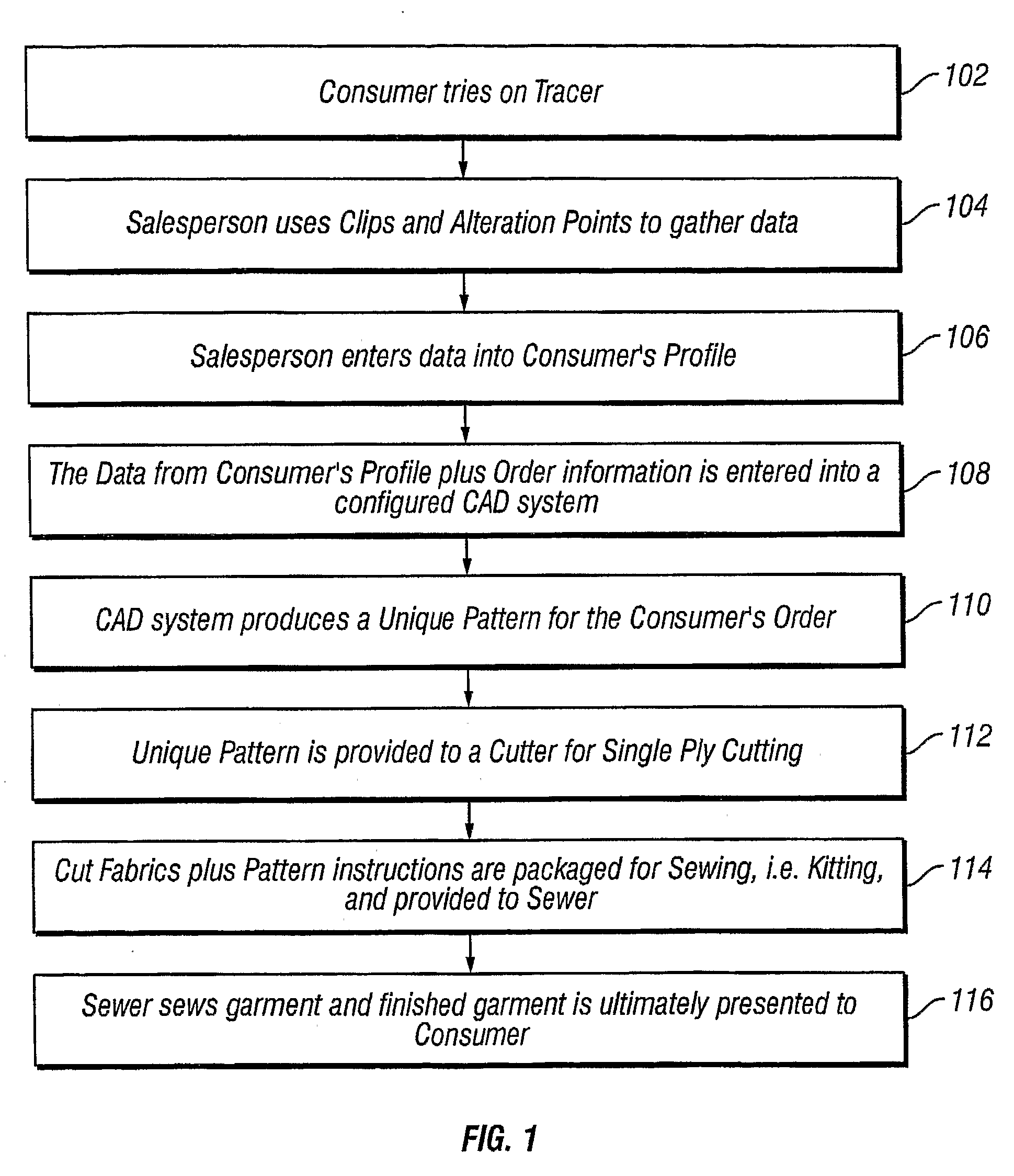

[0043]A unique approach to apparel mass-customization is provided. A technique is provided that is scalable, i.e. built from the ground up to easily roll out and implement in the field. It is easy and familiar to the customer, i.e. a process is provided that mirrors the existing customer experience of trying on a pair of pants. A rich back-end technology is provided that a company can manage in-house and ensure simplicity and ease for roll out in the field. Stores don't need to invest in complex technology, commit large amounts of selling space, or engage in sophisticated training of their staff. A technology is provided that is includes an engine for mass customization of apparel for companies from high end retail to low end retail and any brand or private label retailer. Using the provided base technology, retailers are allowed to improve customer retention, inventory turns, and margins by implementing the technology.

[0044]Retailer Benefits

[0045]A technology is provided that enabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com