Thin belt continuous casting austenitic stainless steel belt and manufacturing method thereof

A technology of austenitic stainless steel and manufacturing method, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of cost increase, pitting corrosion resistance decrease, crack tendency intensification, etc., to achieve easy control and reduce investment Cost and operating costs, the effect of simple and stable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The composition of the embodiment is shown in Table 1, and the process route is shown in Table 2. In the process route of Table 2, pickling process is required before cold rolling process 1 and cold rolling process 2.

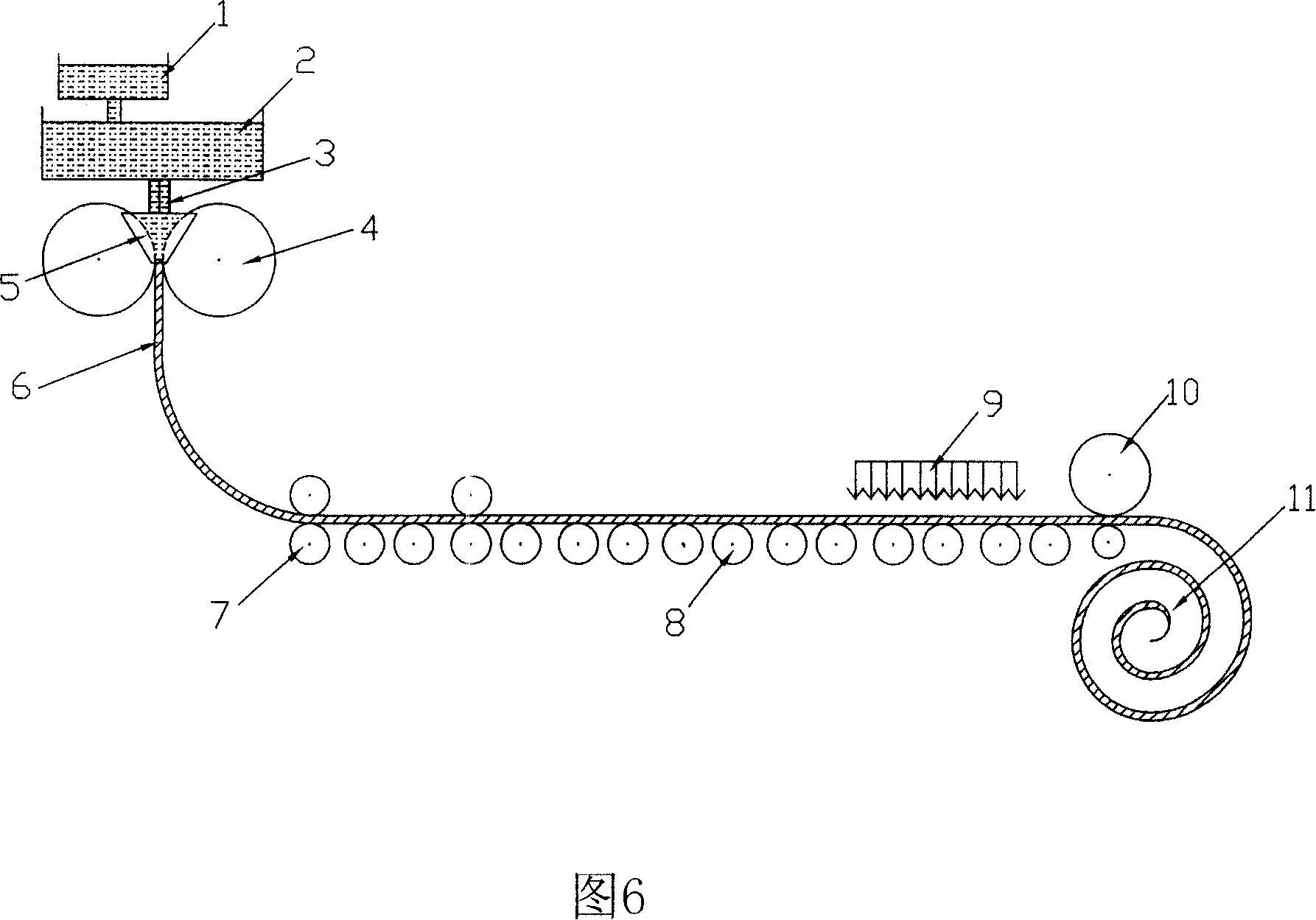

[0050] Referring to Figure 6, the molten steel that meets the composition requirements is passed from the ladle 1 through the tundish 2 and the submerged nozzle 3 into the molten pool formed by the rotating water-cooled crystallization roller 5 and the side sealing plate 5, and is cooled by the water-cooled crystallization roller 4 to form a 1-5mm The casting belt 6, the casting belt passes through the pinch roller 7, the conveying roller table 8 and the cooling control device 9, so that the temperature of the casting belt is lower than 600°C, then passes through the pinch roller 10 before coiling, and enters the coiler 11. The cast strip unloaded from the coiler is kept at a temperature of 1050-1150°C for 5-8 minutes, and then air-cooled for solid solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com