High grade non-oriented silicon steel produced by continuous casting and rolling of sheet billet and production method thereof

A thin slab continuous casting, oriented silicon steel technology, applied in the field of non-oriented silicon steel and its manufacturing, can solve the problems of unresolved, corrugated defects of steel strips, increased iron loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in detail below:

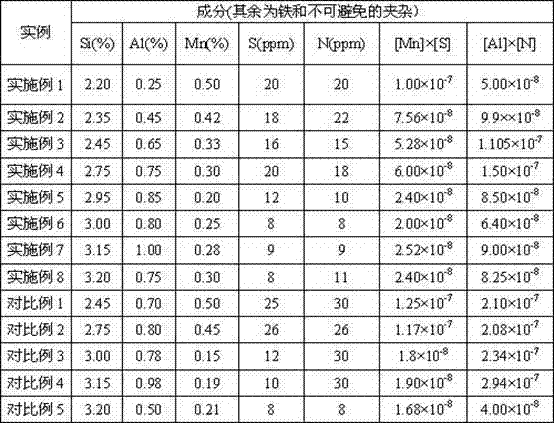

[0039] Table 1 is the value list of the chemical components of each embodiment of the present invention and comparative examples;

[0040] Both the examples and the comparative examples are produced by continuous casting and rolling of thin slabs. The embodiment defines the contents of Al, N, Mn, S and their concentration product.

[0041] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

[0042] The main difference between the embodiment and the comparative example is that the embodiment adopts continuous casting liquid core reduction, casting slab into the furnace at high temperature, rapid heating, high temperature and large reduction, smoothing, high temperature normalization, light reduction in the last pass of cold rolling and low Dew point small tension finished annealed.

[0043] Table 3 is a list of the performance tests of the various embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com