Austenic stainless steel and method for manufacturing same

A technology of austenitic stainless steel and a manufacturing method, which is applied in manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of reducing steel plasticity and corrosion resistance, high process cost and labor cost, poor corrosion resistance, etc. , to achieve the effect of reducing martensite content, low annealing temperature and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

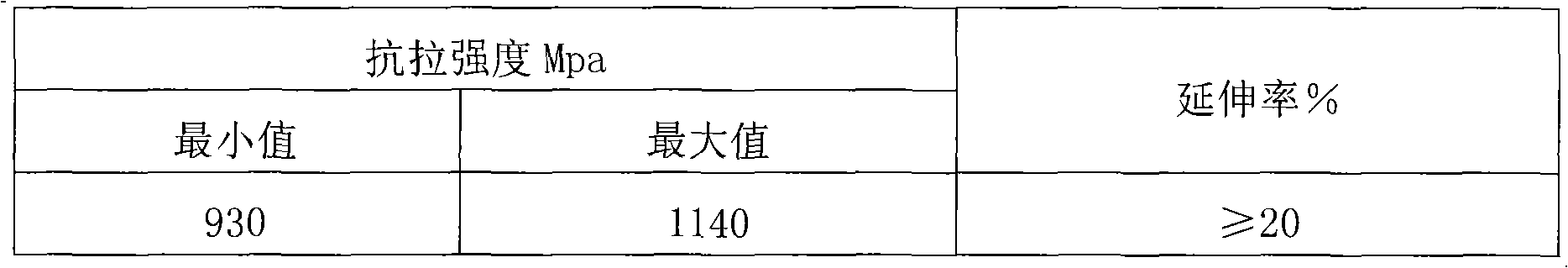

[0036] 1. An austenitic stainless steel, the weight percentage of its chemical composition is: C: 0.008%, Si: 0.3%, Mn: 0.6%, Cr: 18%, Ni: 7.5%, N: 0.1%, P≤ 0.040%, S≤0.03%, the rest is Fe and unavoidable impurity elements, among them, Md30=413-9.5(%Ni)-13.7(%Cr)-8.1(%Mn)-9.2(%Si)-462( The value of %C+%N) is 20.

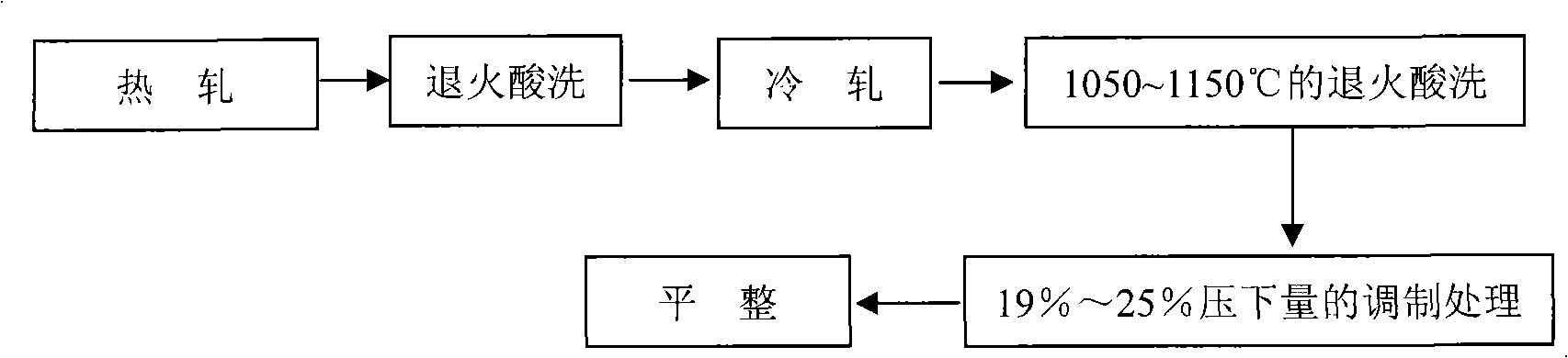

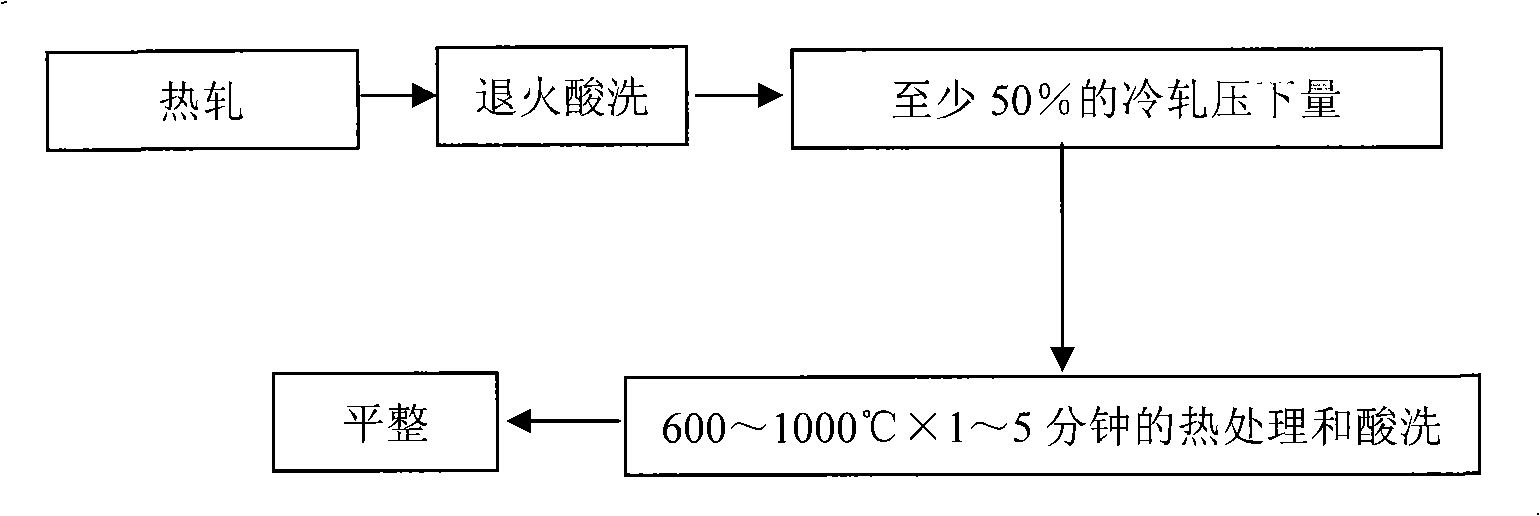

[0037] 2. (See figure 2 ) The manufacturing method of the austenitic stainless steel comprises the steps:

[0038] (1) Preparing steel ingots or slabs according to the weight percentage distribution of the above-mentioned chemical components;

[0039] (2) Hot rolling, heated in a heating furnace, the temperature range is 1210 ° C, and rolled into strip steel or flat plate after thermal deformation at 900 ° C;

[0040] (3) Annealing and pickling, solution heat treatment at a temperature of 1000 ° C, and the heat treatment time is determined according to 5 minutes / mm;

[0041] (4) cold rolling, cold rolling reduction is 50%;

[0042] (5) Heat treatment and pickli...

Embodiment 2

[0044] 1. An austenitic stainless steel, the weight percentage of its chemical composition is: C: 0.02%, Si: 0.5%, Mn: 1.0%, Cr: 17.0%, Ni: 7%, N: 0.12%, P≤ 0.040%, S≤0.03%, the rest is Fe and unavoidable impurity elements, among them, Md30=413-9.5(%Ni)-13.7(%Cr)-8.1(%Mn)-9.2(%Si)-462( The value of %C+%N) is 36.

[0045] 2. The manufacturing method of the austenitic stainless steel comprises the following steps:

[0046] (1) Preparing steel ingots or slabs according to the weight percentage distribution of the above-mentioned chemical components;

[0047] (2) Hot rolling, heated in a heating furnace, the temperature range is 1230 ° C, and rolled into strip steel or flat plate after thermal deformation at 1000 ° C;

[0048] (3) Annealing and pickling, solution heat treatment at a temperature of 1000 ° C, and the heat treatment time is determined according to 4 minutes / mm;

[0049] (4) cold rolling, cold rolling reduction is 50%;

[0050] (5) Heat treatment and pickling, pic...

Embodiment 3

[0052] 1. An austenitic stainless steel, the weight percentage of its chemical composition is: C: 0.008%, Si: 0.3%, Mn: 0.6%, Cr: 18%, Ni: 7.5%, N: 0.1%, P≤ 0.040%, S≤0.03%, the rest is Fe and unavoidable impurity elements, among them, Md30=413-9.5(%Ni)-13.7(%Cr)-8.1(%Mn)-9.2(%Si)-462( The value of %C+%N) is 38.

[0053] 2. The manufacturing method of the austenitic stainless steel comprises the following steps:

[0054] (1) Preparing steel ingots or slabs according to the weight percentage distribution of the above-mentioned chemical components;

[0055] (2) Hot rolling, heated in a heating furnace, the temperature range is 1250 ° C, and rolled into strip steel or flat plate after thermal deformation at 1050 ° C;

[0056] (3) Annealing and pickling, performing solution heat treatment at a temperature of 1100 ° C, and the heat treatment time is determined according to 3.5 minutes / mm;

[0057] (4) Cold rolling, the cold rolling reduction is 55%;

[0058] (5) Heat treatment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com