Stainless steel environment-friendly pickling solution

A kind of pickling solution, stainless steel technology, applied in the field of stainless steel environmental protection pickling solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

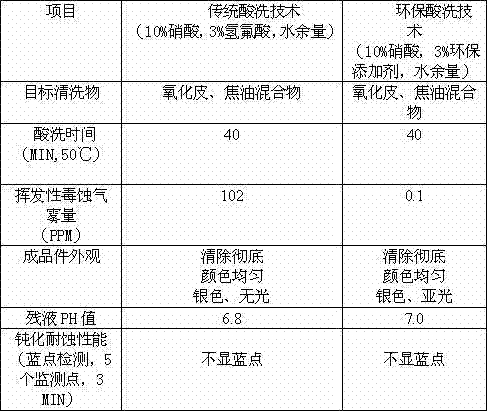

Image

Examples

Embodiment 1

[0105] As a preference: the environmental protection additive is compounded by the following components by weight:

[0106] Pickling dissolution accelerator 12-14kg, interface barrier adsorbent 1.2-2kg, double gas mask coagulant 0.4-1.2kg, regeneration agent 0.8-2kg, oxidation supplement 1.2-2kg, oxidation energy activator 1.2-2.4kg, new Complexing agent 6-8kg, complexing catalyst 2kg, corrosion inhibitor 0.8-1.2 kg, fog suppressant 0.4-2kg, penetrant 0.08-0.3 kg, passivator 5-10kg, brightener 0.8-1.2kg;

[0107] As a preference: the environmental protection additive is compounded by the following components by weight:

[0108] Pickling dissolution accelerator: compounded with 1-5 kg of ethylenediamine and 8-12 kg of aminotrimethylene phosphonic acid;

[0109] Interface barrier adsorbent: compounded with 0.5 kg of polymerized ethylene glycol, 0.5-1 kg of organic amine antistatic agent, and 0.2-0.5 kg of diethylene glycol;

[0110] Double gas mask coagulant: compounded by ...

Embodiment 2

[0129] Effective concentration of nitric acid: 10-30% (mass percentage)

[0130] Concentration of environmental protection additives: 3-5% (mass percentage)

[0131] (2) Quantitative preparation example:

[0132] ① Nitric acid (65% type including specification): 200-500 kg; additive: 30-50 kg; water: 770-450 kg;

[0133] ② Nitric acid (98% type including specification): 120-300 kg; additive: 30-50 kg; water: 850-650 kg.

[0134] (3) Groove matching method:

[0135] ① Add fresh water that meets the metering requirements;

[0136] ② Adding "environmental protection additives" that meet the metering requirements;

[0137] ③ Add the "nitric acid" that conforms to the metering;

[0138] ④ Stir until completely dissolved.

[0139] Quantitative maintenance of pickling solution:

[0140] 1. Overview of bath maintenance:

[0141] ① As the pickling process proceeds, a certain amount of "environmental protection additives" should be added to each shift to maintain the normal prog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com