Composite artificial ligament and preparation method thereof

A technology of artificial ligament and weaving net, applied in ligament, medical science, muscle and other directions, can solve the problems of artificial ligament elongation, foreign body rejection, ligament surface cells and tissues cannot grow normally, etc., and achieve the effect of promoting growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

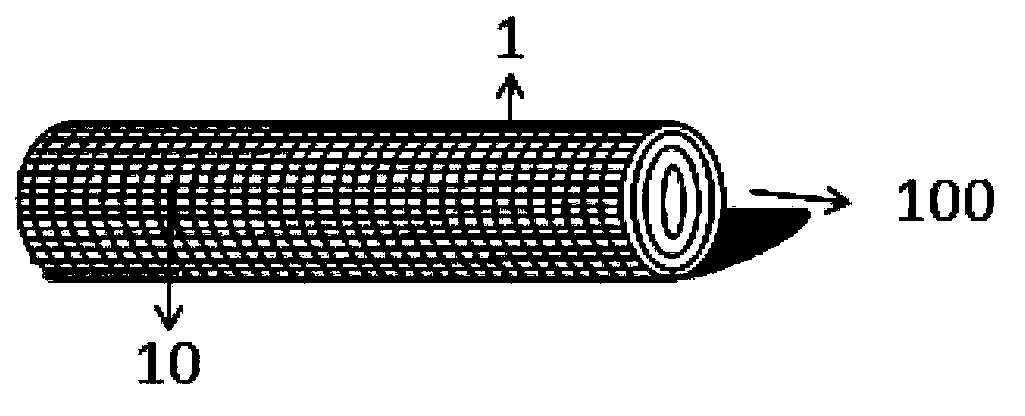

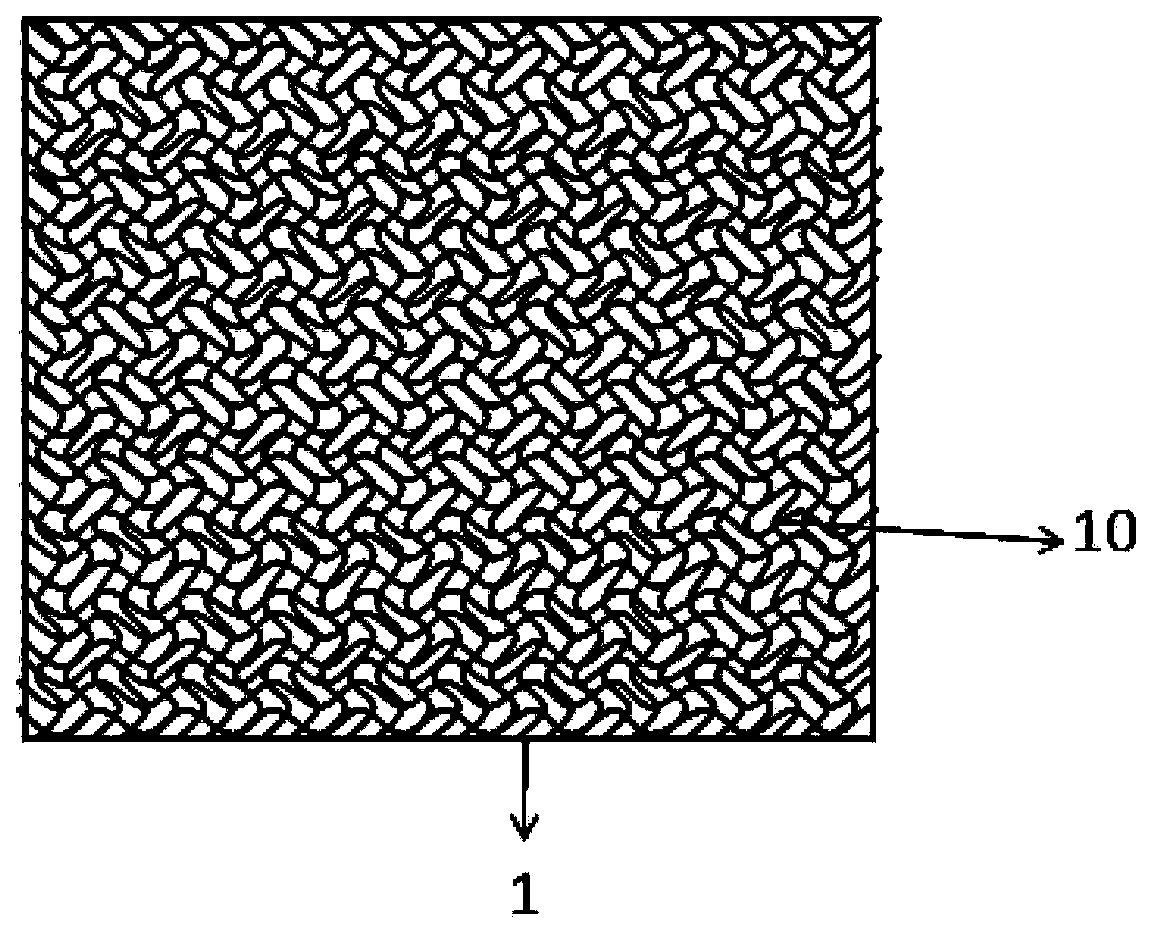

[0036] In the preparation method of the present invention, it is formed by spinning or spinning, compounding into threads, weaving into nets, rolling the nets into rods and reinforcing them with non-woven needle punching technology by spinning or spinning several components in sequence, so that even in the degradation process , The structure of the product still maintains a mesh shape, and the mesh gradually becomes larger, which is more suitable for the attachment of surrounding tissues and the repair and growth of ligament tissue.

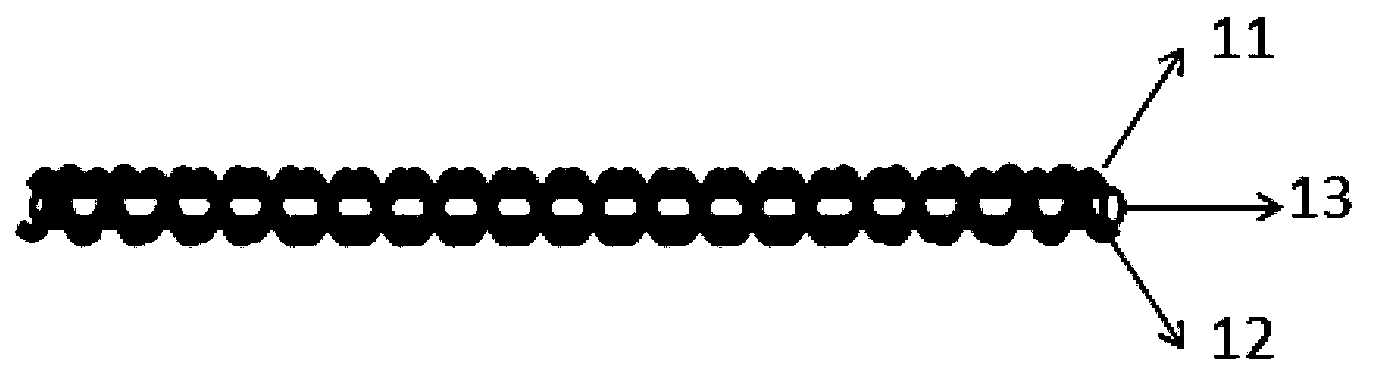

[0037] The semi-degradable composite artificial ligament of the present invention is composed of three components with different degradation properties: component one, component two and component three through spinning or spinning, compounding into threads, weaving into nets, rolling the nets into rods and using them. It is reinforced by spinning needle punching technology. The preparation method of the composite artificial ligament of the present i...

Embodiment 1

[0048] Choose collagen and poly(ε-caprolactone) as two raw materials, use surgical suture preparation method to spun into filament or bundle respectively, choose polyethylene terephthalate to spun by melt spinning method Filament or bundle, the diameter of single filament is 1-50μm, and the number of filaments contained in a single bundle is 1-20.

[0049] The three-component tows are prepared according to the number ratio of 1:1:1 to prepare a thread with the component three tow as the inner core, and the component one and the second component tow are entangled on the inner core, and pass through the web forming machine Weave the threads into a net-like structure with a mesh diameter ranging from 150 to 300 μm. Finally, the net-like structure is rolled into a 6 mm rod-like structure. Non-woven needle punching technology is used to entangle the threads in the rod-like structure to form a net. Hole staggered structure.

[0050] The initial tensile strength of the artificial ligamen...

Embodiment 2

[0052] Two kinds of raw materials, polyglycolic acid and poly β-hydroxybutyrate are selected, and the surgical suture preparation method is used to spun into filaments or bundles, and the ultra-high molecular weight polyethylene is spun into filaments or by melt spinning. Bundle shape, in which the diameter of single filament is 1-50μm, and the number of filaments contained in a single bundle is 1-20.

[0053] The three component tows are prepared according to the number ratio of 1:1:2 to prepare a thread with the component three tow as the inner core, and the component one and the second component tow are entangled on the inner core, and pass through the web forming machine Weave the threads into a net-like structure with a mesh diameter ranging from 150 to 300 μm. Finally, the net-like structure is rolled into a rod-like structure with 10 mm. The non-woven needle punching technology is used to entangle the threads in the rod-like structure to form a mesh. Staggered structure.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com