Method for preparing high-porosity porous ceramic membrane support

A technology of porous ceramic membrane and high porosity, which is applied in the field of preparation of high-porosity porous ceramic membrane support body, which can solve the problems of poor acid and alkali corrosion resistance, large pores of the support body, and low mechanical strength, so as to improve the sintering degree , Increased porosity, and the effect of increasing the degree of neck connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

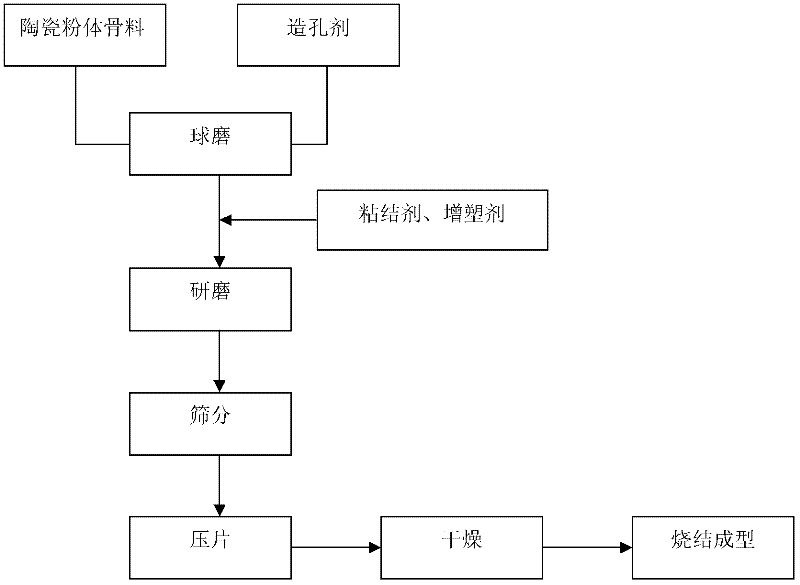

Method used

Image

Examples

Embodiment 1

[0019] After accurately weighing SiC (average particle size of 3 microns, purity 95.2%) and starch powder (average particle size of 35 microns) according to the mass ratio of 17:1, and high alumina ceramic balls according to the mass ratio of 1:1.2 Add it into a 1.5L rigid polyethylene bottle, place the polyethylene bottle on a ball mill and mix for 12 hours, add respectively 9% binder methyl cellulose and 9% plasticizer polyethylene glycol, fully grind for 2 hours, sieve with a 40-mesh sieve to obtain a powder with uniform particle size distribution, inject the powder into a metal abrasive tool, and use a powder tablet press to maintain it at 10MPa for 2 minutes Dry press molding to obtain a sheet-like support wet body with a diameter of Φ40mm. The wet billets were placed in an oven at a rate of 0.8°C / min to 140°C and dried for 12 hours. Place the dried support body in an electric furnace to raise the temperature to 550°C at a rate of 1°C / min and keep it for 2.5 hours; then ...

Embodiment 2

[0021] After accurately weighing SiC (average particle size of 8 microns, purity of 99.7%) and activated carbon powder (average particle size of 30 microns) according to the mass ratio of 10:1, and high alumina ceramic balls according to the mass ratio of 1: 1.5 Add to a 1.5L rigid polyethylene bottle, place the polyethylene bottle on a ball mill and mix for 24 hours, add 8% binder dextrin and 8% of the powder mass after ball milling to the raw materials after ball milling % plasticizer polyvinyl alcohol, fully grind for 1h, sieve with a 30-mesh sieve to obtain a powder with uniform particle size distribution, inject the powder into a metal abrasive tool, and keep it dry for 1.5min at 7MPa using a powder tablet press Press molding to obtain a sheet-shaped support body wet body with a diameter of Φ30mm. The wet billets were placed in an oven at a rate of 0.6°C / min to 130°C and dried for 20 hours. Place the dried support body in an electric furnace to raise the temperature to 6...

Embodiment 3

[0023] Aluminum oxide (average particle size is 6 microns, purity is 99.7%) and starch powder (average particle size is 30 microns) are accurately weighed according to the mass ratio of 8:1, and high alumina ceramic balls are used according to the mass ratio of 1 : 2 joins in the 1.2L hard polyethylene bottle, puts the polyethylene bottle on the ball mill and mixes 30h, in the raw material after the ball mill, add respectively the binder paraffin that quality is 7% of the powder quality after the ball mill and 7% % Plasticizer polyvinyl alcohol, fully grind for 1.5h, sieve with a 40-mesh sieve to obtain a powder with uniform particle size distribution, inject the powder into a metal abrasive tool, and use a powder tablet press to maintain dry pressing at 8MPa for 1min Forming to obtain a sheet-shaped support wet body with a diameter of Φ30mm. The wet billet was placed in an oven and heated to 120°C at a rate of 0.5°C / min and dried for 24 hours. Place the dried support body in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com