Application of fatty acid ester end group hyperbranched polyester as high polymer material viscosity reducing and toughening agent

A technology of hyperbranched polyester and polymer materials, applied in the field of fatty acid ester terminal hyperbranched polyester type viscosity reducing and toughening agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Add the fourth-generation Boltorn type hyperbranched polyester and excess n-octadecanoic acid into a three-necked flask, then add 0.3wt% p-toluenesulfonic acid as a catalyst, under the protection of nitrogen, mechanically stir, react at 140°C for 3 hours, and pump Vacuum to remove the water produced by the reaction. The product is a light yellow waxy solid. After being dissolved in chloroform and anhydrous ethanol, precipitation, drying and purification, the fourth generation n-octadecanoate-terminated hyperbranched polyester is obtained, and its viscosity is 483.35mPa·s.

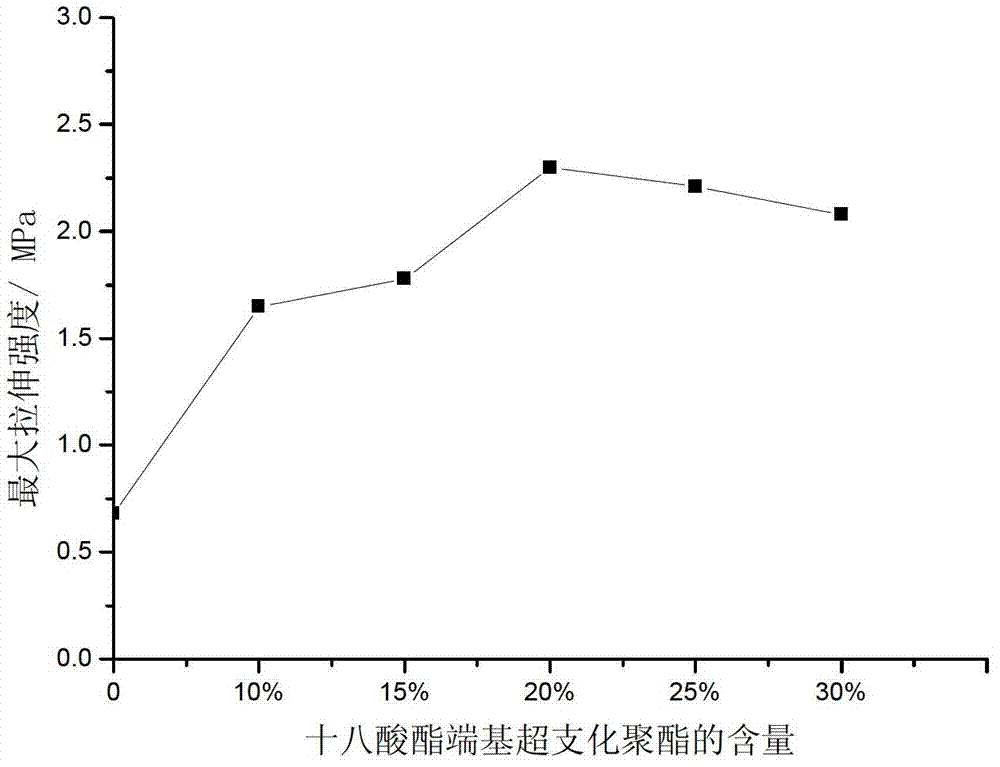

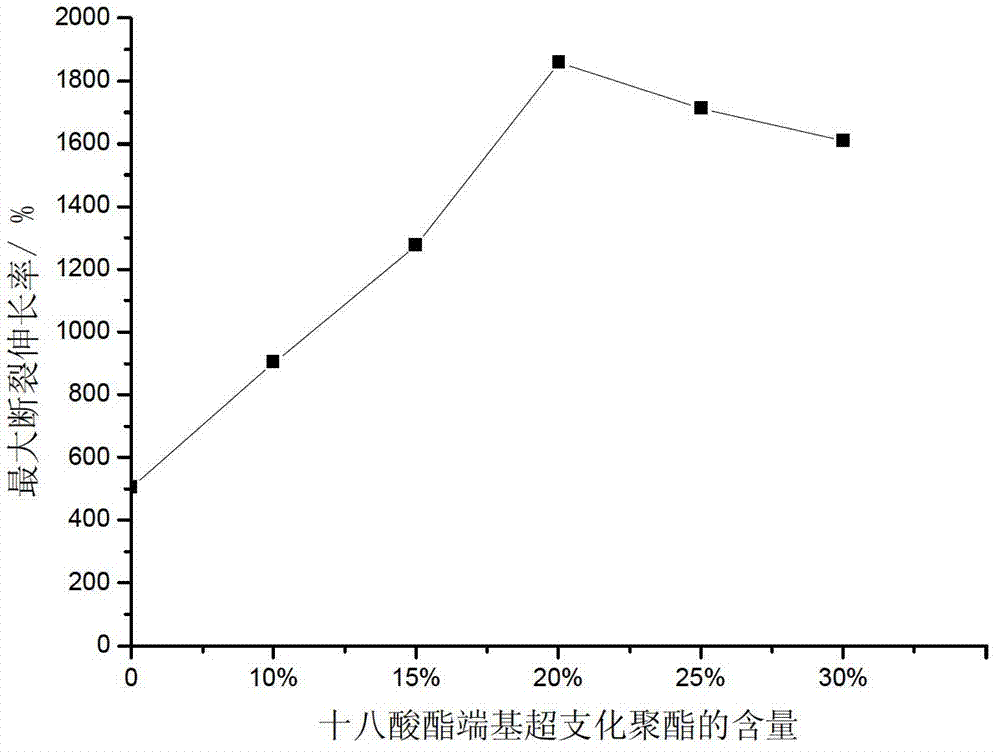

[0043] The above-mentioned 4th generation n-octadecanoate-terminated hyperbranched polyester and HTPB type polyurethane prepolymer (hydroxyl-terminated polybutadiene HTPB and isophorone diisocyanate IPDI) are weighed according to the formula consumption (wherein adjusting positive The percentages by weight of octadecanoate-terminated hyperbranched polyester to the total weight of n-octadecanoate-termi...

Embodiment 2

[0047] The synthetic method of the fourth generation n-octadecanoic acid terminal hyperbranched polyester is the same as in Example 1.

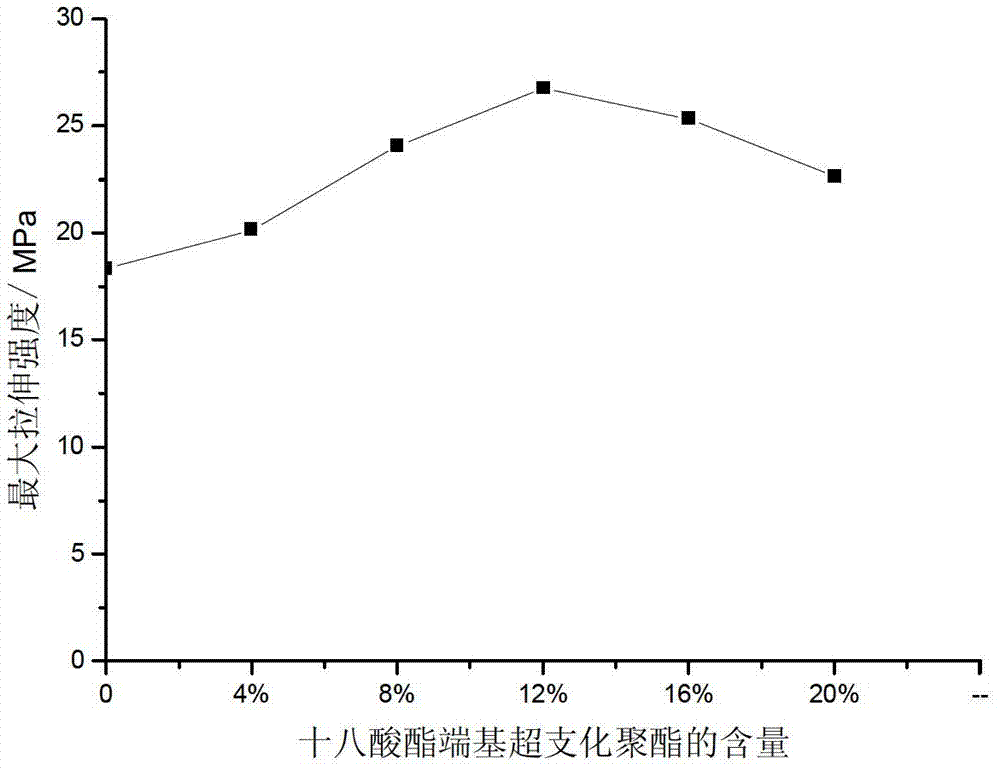

[0048] Weigh the fourth-generation octadecanoate-end hyperbranched polyester and high-density polyethylene according to a certain composition ratio (wherein the fourth-generation octadecanoate-end hyperbranched polyester accounts for the proportion of n-stearate The percentages by weight of the end-group hyperbranched polyester and the total weight of high-density polyethylene are respectively 4%, 8%, 12%, 16% and 20%), which are mixed by a twin-roller mixer, and then granulated. The mixed masterbatch was tested for viscosity (Table 2) and mechanical properties ( image 3 , Figure 4 ). Viscosity test results show that the initial viscosity of high-density polyethylene is 5486.46mPa·s, and its viscosity decreases to 3320.68mPa·s after adding 20% of the fourth-generation octadecanoate-terminated hyperbranched polyester. The test results o...

Embodiment 3

[0053] The synthetic method of the 4th generation n-octadecanoic acid end group hyperbranched polyester is the same with embodiment 1.

[0054] The fourth generation n-octadecanoate end group hyperbranched polyester and polybutylene phthalate are weighed according to a certain composition ratio (wherein the fourth generation n-octadecanoate end group hyperbranched polyester The percentage by weight of the total weight of octadecanoate-terminated hyperbranched polyester and polybutylene phthalate is 4%, 8%, 12%, 16% and 20%), using a two-roller mixer Knead and then granulate. The mixed masterbatch was tested for viscosity (Table 3) and mechanical properties ( Figure 5 , Figure 6 ). Viscosity test results show that the initial viscosity of polybutylene phthalate is 6836.44mPa·s, and its viscosity drops to 4032.35mPa·s after adding 20% of the fourth-generation octadecanoate-terminated hyperbranched polyester. The test results of mechanical properties show that the maximum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com