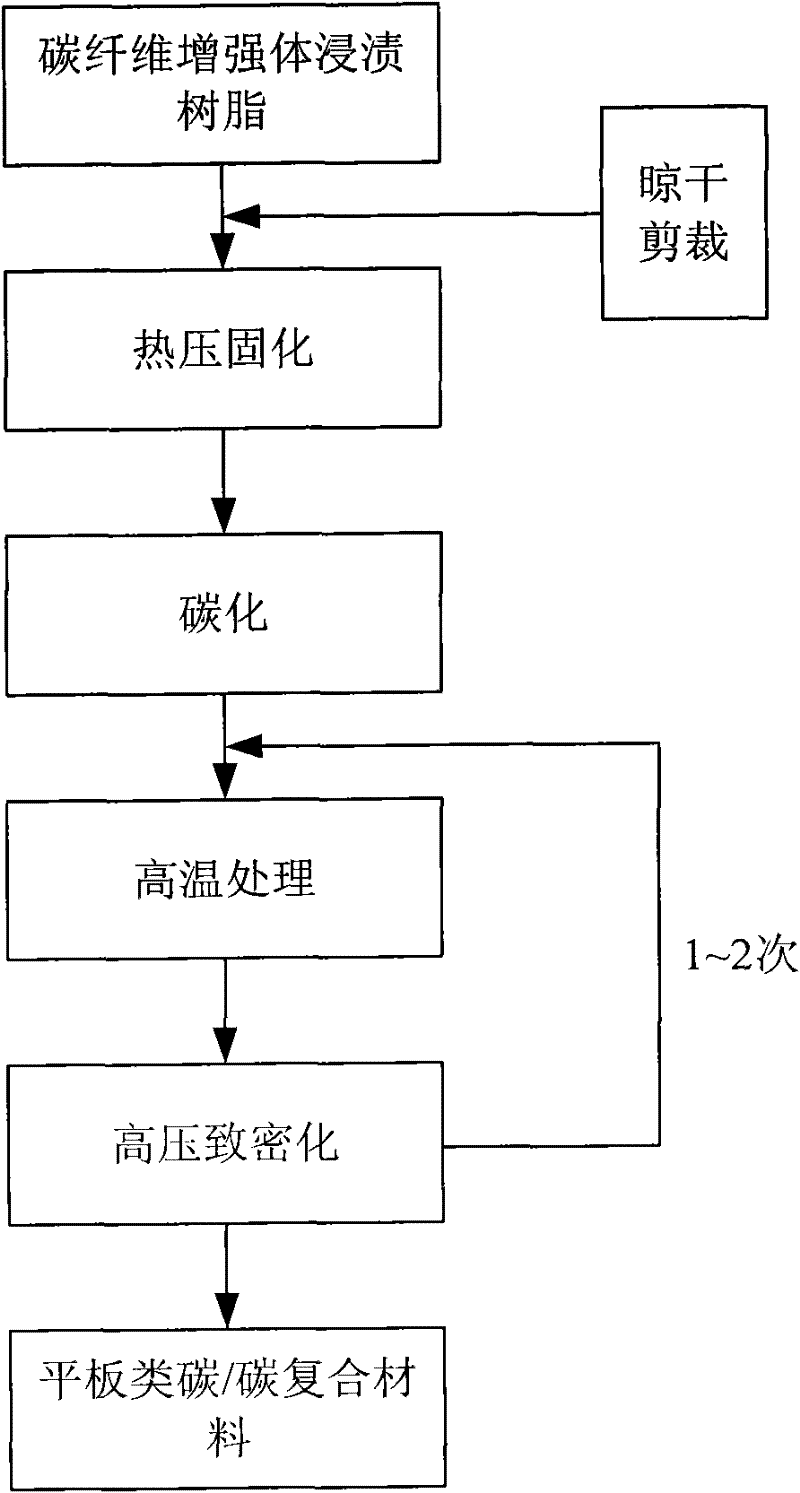

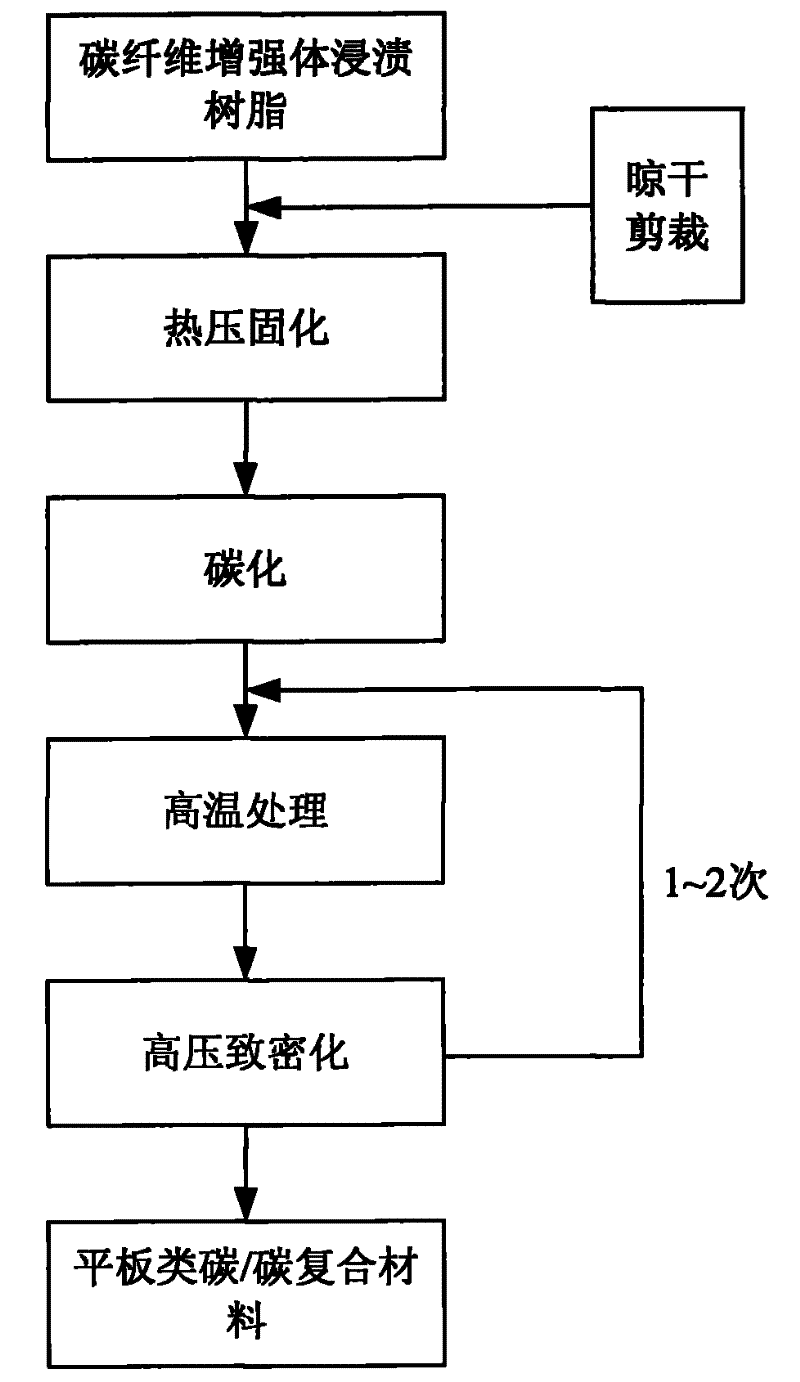

Method for rapidly forming flat plate carbon/carbon composite material

A technology of carbon composite materials and forming methods, which is applied in the forming of carbon/carbon composite materials and the field of rapid prototyping of flat carbon/carbon composite materials, which can solve the problems of long densification cycle, reduced production efficiency, and increased preparation difficulty. Achieve the effects of good tissue uniformity, reduce preparation costs, and improve densification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] First put the carbon cloth into the prepared resin solution for impregnation, the solid content of the resin solution is 45%; then take it out to dry naturally, cut it into about 30 layers of square carbon cloth with a plane size of 400×400mm, and stack them together; Spread the release agent evenly on the upper and lower tables of the hot press, spread the stacked carbon cloth on the lower table, move the table so that the upper table only rests on the upper surface of the carbon cloth layer; turn on the power to make the upper and lower tables Start to heat up, preheat it through the heat conduction of the upper and lower tables to the carbon cloth layer and cure it at 200°C. The thickness of the cured material is about 11mm (the curing pressure can be adjusted appropriately to control the thickness); put the cured composite material into the carbonization In the furnace, vacuumize to remove the air inside the furnace body, then pass inert gas to normal pressure, turn ...

Embodiment 2

[0039]First take a piece of carbon fiber felt with a size of 300×300×25mm, then put it into a resin solution with a solid content of 50%, soak it for 8 hours under normal pressure; then take it out and dry it naturally to evaporate part of the resin solvent; 1. Evenly coat the release agent on the lower table, spread the carbon fiber felt on the lower table of the heat press machine, move the table so that the upper table only rests on the upper surface of the carbon fiber fabric; Facing the heat conduction of the fabric, it is preheated and cured at 280°C; the cured composite material is placed in a carbonization furnace, vacuumed to remove the air inside the furnace, and then the inert gas is introduced to normal pressure, and the power is turned on and the furnace The temperature is raised to 800°C for carbonization; the carbonized carbon / carbon composite material is placed in a high-temperature graphitization furnace, vacuumed to remove the air inside the furnace, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com