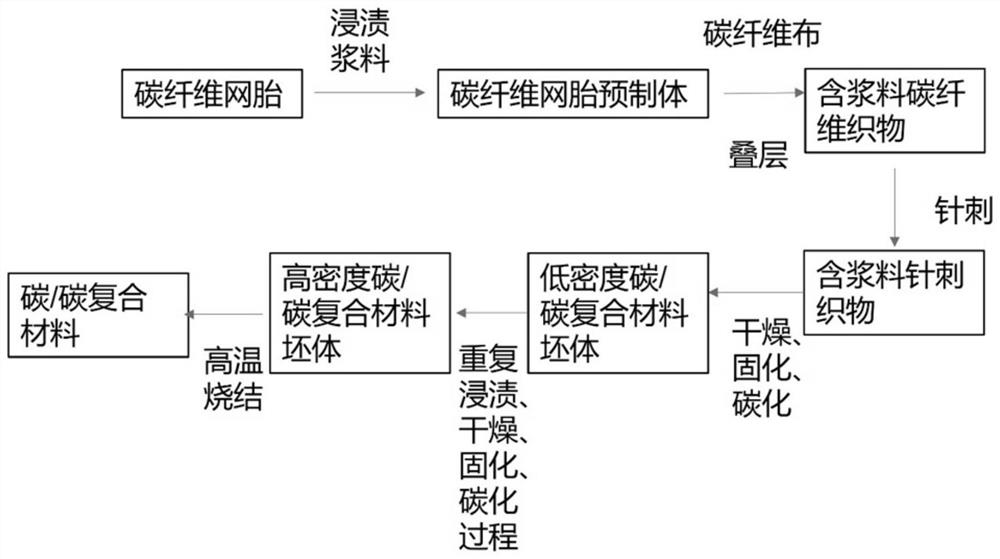

Wet needling process for preparing carbon/carbon composite material

A carbon composite material and acupuncture technology, applied in the field of wet acupuncture, can solve the problems of long dipping time and many dipping times, and achieve the effects of improving process safety, reducing dipping times and reducing fiber damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Step 1, the chopped carbon fiber mesh tire with a thickness of 1mm (the chopped fiber mesh tire prepared from Toray T700-12K carbon fiber, the mesh tread density is 80g / m 2 ) into the slurry for impregnation to obtain a carbon fiber mesh tire preform, wherein the quality of the carbon fiber mesh tire accounts for 20±3% of the mass of the slurry.

[0046]Step 2, using a graphite flat plate with screen holes as a tooling, laminating the carbon fiber plain weave with the carbon fiber mesh preform obtained in step 1 to obtain a slurry-containing carbon fiber fabric, and the slurry-containing carbon fiber fabric is needled on a needling machine. puncture to obtain a needle-punched fabric containing pulp, heating (drying) to remove the ethanol solvent in the needle-punching fabric containing pulp, the heating temperature is 80 °C (80-90 °C is equivalent to 80 °C), the time is 12h, and then the 500°C (400-600°C is equivalent to 500°C) curing for 32h (24-48h is equivalent to 32...

Embodiment 2

[0051] Step 1, the carbon fiber mesh tire with a thickness of 1mm (the chopped fiber mesh tire prepared from Toray T700-12K carbon fiber, the mesh tread density is 80g / m 2 ) into the slurry and evenly impregnated to obtain a preform containing a carbon fiber mesh tire, and the weight of the carbon fiber mesh tire is 15±3% of the impregnated slurry.

[0052] Step 2, using a graphite flat plate with screen holes as a tooling, laminating the carbon fiber plain weave with the carbon fiber mesh preform obtained in step 1 to obtain a slurry-containing carbon fiber fabric, and the slurry-containing carbon fiber fabric is needled on a needling machine. Needle-punched fabrics containing pulp are obtained by puncturing, and then dried at 85°C (the effect of 80-90°C is equivalent to 85°C) for 12 hours, and cured at 500°C (the effect of 400-600°C is equivalent to 500°C) for 32 hours (the effect of 24-48h is equivalent to that of 500°C). 32h has the same effect), and then carbonized at 900...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com