Preparation method of carbon fiber three-dimensional fabric enhanced polyimide-carbon based dual substrate composite material

A three-dimensional fabric and polyimide technology is applied in the field of preparation of carbon fiber three-dimensional fabric reinforced polyimide-carbon-based dual-element matrix composite materials, which can solve the problems of inability to serve for a long time and the reduction of mechanical properties of materials, and achieve an optimized interface. Mechanical properties, optimized fracture toughness, improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1 Carbon fiber three-dimensional fabric reinforced polyimide-carbon-based binary matrix composite (PI-C / C F ) preparation

[0061] In this implementation case, a method for preparing a carbon fiber three-dimensional fabric reinforced polyimide-carbon-based binary matrix composite material includes the following steps:

[0062] 1) Using carbon fiber three-dimensional fabric as a prefabricated body, the carbon matrix is introduced through chemical vapor infiltration (CVI) and liquid phase impregnation-pyrolysis (PIP) processes to prepare a carbon-based composite blank with a density of 1.30g / cm3.

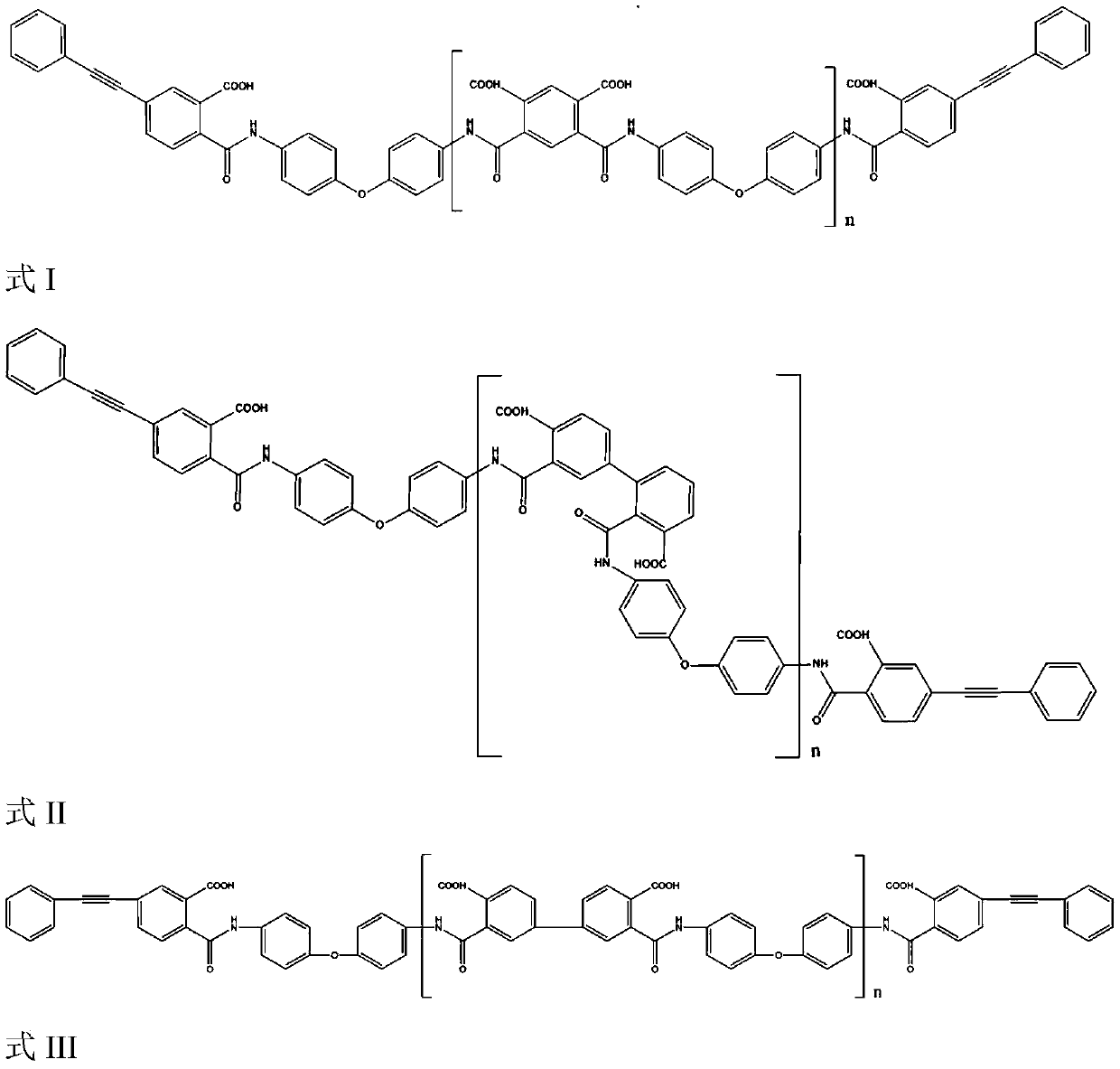

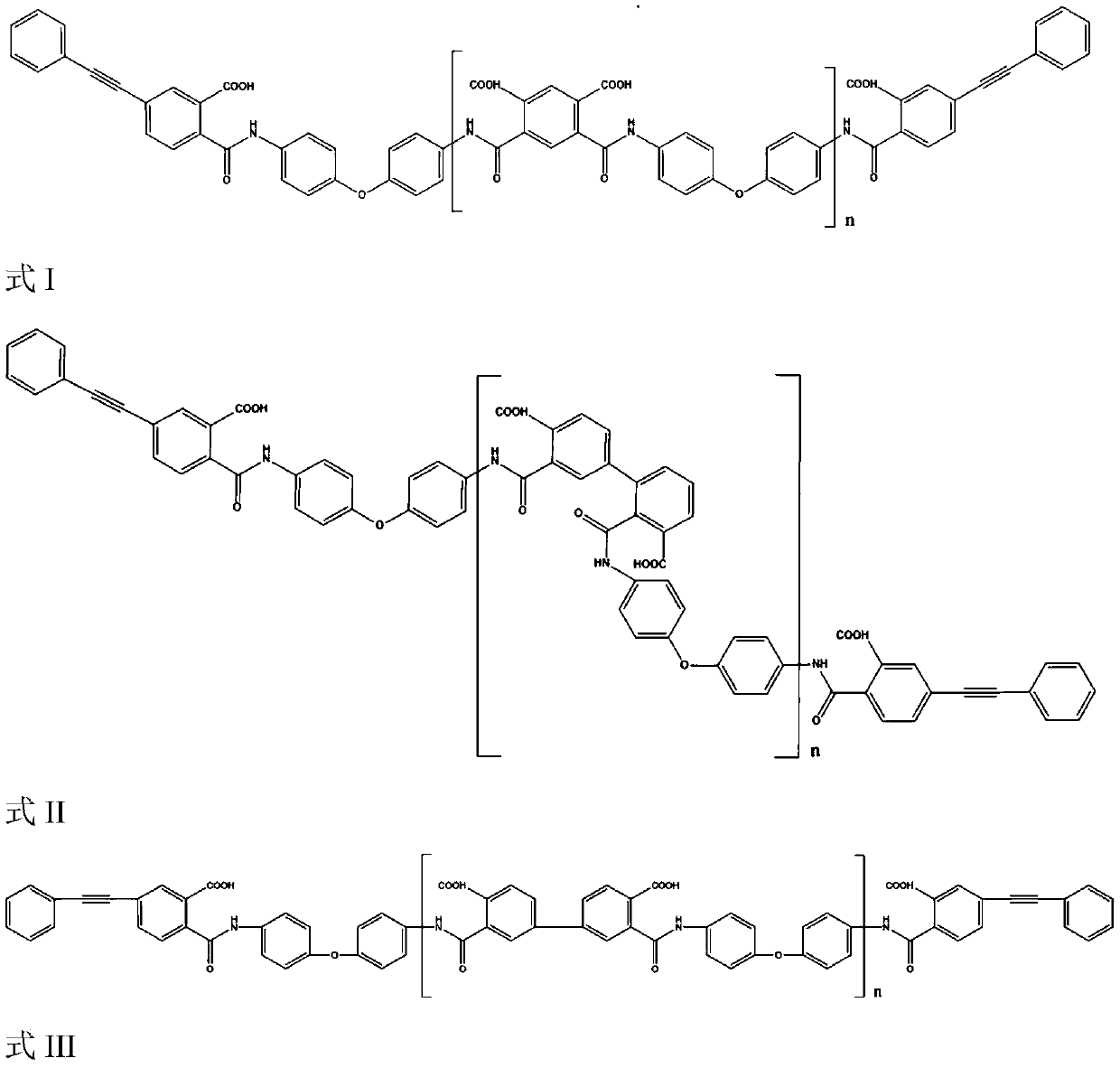

[0063] 2) Put the carbon-based composite material blank prepared in step (1) into the impregnation reaction kettle, and vacuumize at room temperature to make the pressure in the kettle reach 10 2 Pa, then the polyamic acid resin A (chemical structural formula as shown in formula I) that solid content is 40% is introduced in the still, impregnates blank 1.0h; Subseq...

Embodiment 2

[0066] Example 2 Preparation of carbon fiber three-dimensional fabric reinforced polyimide-carbon-based binary matrix composite (PI-C / CF)

[0067] In this embodiment, a method for preparing a carbon fiber three-dimensional fabric reinforced polyimide-carbon-based binary matrix composite material comprises the following steps:

[0068] 1) Using carbon fiber three-dimensional fabric as a prefabricated body, the carbon matrix is introduced through chemical vapor infiltration (CVI) and liquid phase impregnation-pyrolysis (PIP) processes to prepare a carbon-based composite material blank with a density of 1.40g / cm3.

[0069] 2) Put the carbon-based composite material blank prepared in step (1) into the impregnation reaction kettle, and vacuumize at room temperature to make the pressure in the kettle reach 10 3 Pa, then the polyamic acid resin B (chemical structural formula as shown in formula II) with a solid content of 38% is introduced into the still, and the blank is impregn...

Embodiment 3

[0072] Example 3 Preparation of carbon fiber three-dimensional fabric reinforced polyimide-carbon-based binary matrix composite (PI-C / CF)

[0073] In this implementation case, a method for preparing a carbon fiber three-dimensional fabric reinforced polyimide-carbon-based binary matrix composite material includes the following steps:

[0074] 1) Using carbon fiber three-dimensional fabric as a prefabricated body, the carbon matrix is introduced through chemical vapor infiltration (CVI) and liquid phase impregnation-pyrolysis (PIP) processes to prepare a carbon-based composite blank with a density of 1.45g / cm3.

[0075] 2) Put the carbon-based composite material blank prepared in step (1) into the impregnation reaction kettle, and vacuumize at room temperature to make the pressure in the kettle reach 10 2 Pa, then the polyamic acid resin C (chemical structural formula as shown in formula III) that solid content is 35% is imported in the still, impregnates blank 0.5h; Subseq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear rate | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com