Nanometer thermoelectric powder material preparing method

A technology of powder materials and thermoelectric materials, which is applied in the field of preparation of nanometer thermoelectric powder materials, can solve the problems of reduced performance of bulk materials, decreased performance or activity, and high oxygen content, and achieves high utilization rate, good morphology and performance. , good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

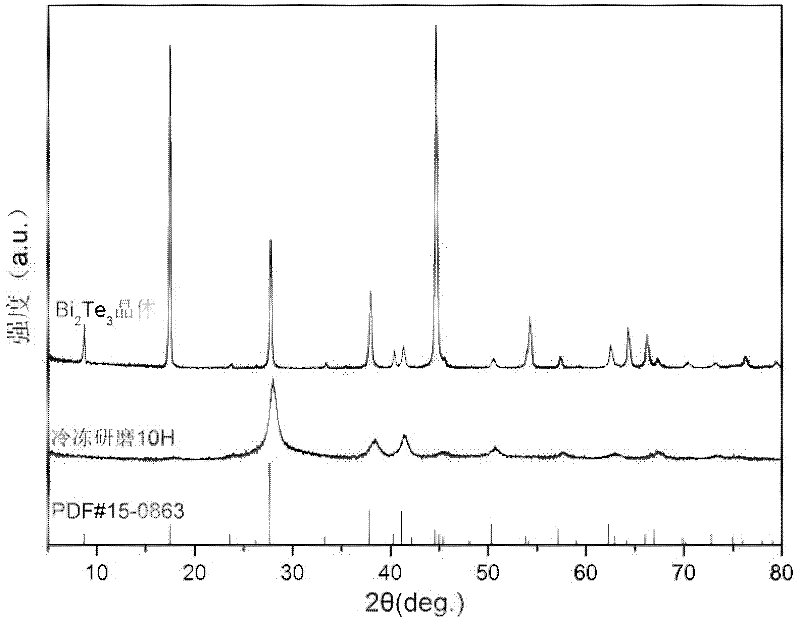

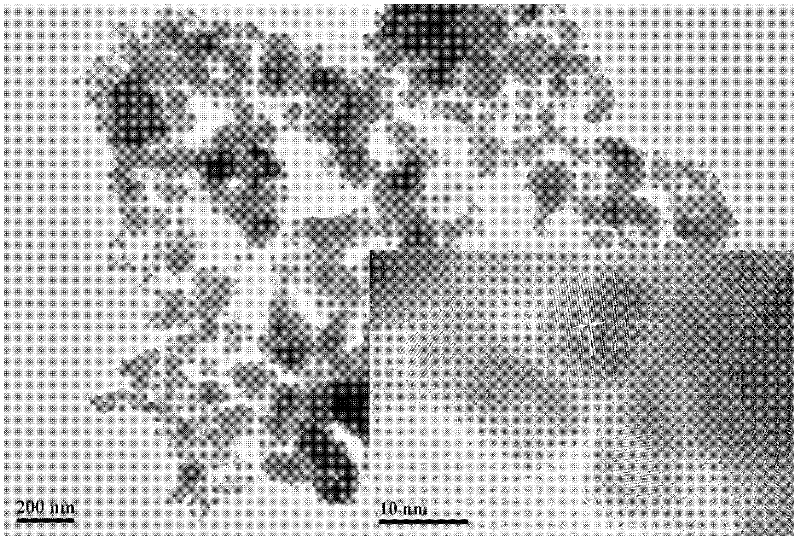

[0026] By Bi 2 Te 3 The crystal material is used as the raw material. First, the crystal material is broken into coarse particles smaller than 5mm in the steel mold. Weigh 9-10g of the sample and put it into a grinding jar together with grinding balls, and then immerse it in a grinder filled with liquid nitrogen. Set the pre-cooling time to 10 minutes, and the grinding time to 10 hours. After the grinding is completed, the nano-scale powder is obtained after vacuum drying. The crystal form of the obtained powder is complete without phase change or decomposition; the grain size is 10-15nm. (see attached figure 1 , 2 )

Embodiment 2

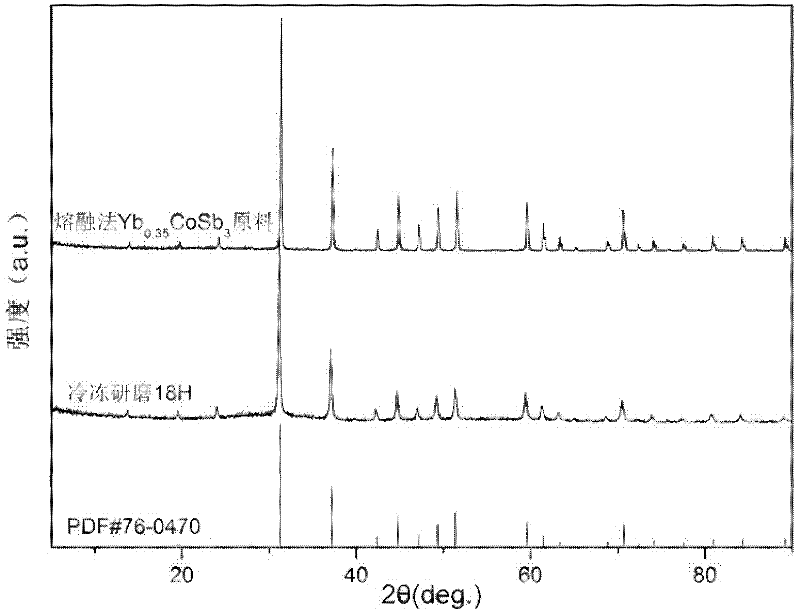

[0028] Use Yb, Co and Sb element powder as raw materials, put them into graphite crucibles according to the mass ratio of 0.35:1:3, and then pack them into sealed quartz tubes (vacuumize inside the tubes), put them into a programmable temperature-controlled furnace, and raise the temperature. After heat preservation and quenching, Yb 0.35 CoSb 3 raw material.

[0029] Take Yb 0.35 CoSb 3 The crystal material is used as the raw material. Firstly, the crystal material is crushed into coarse particles smaller than 5mm in the steel mold. Weigh 9-10g of the sample and put it into the central cylinder together with the steel striker, and then fix it on the cryogenic grinder filled with liquid nitrogen. Set the pre-cooling time to 20 minutes, the frequency to 10 cps, the grinding time to 2 minutes, the re-cooling time to 3 minutes, and the cycle to 10. After 18 hours of freeze-grinding, samples were taken after the air was raised to room temperature, and then vacuum-dried to obtai...

Embodiment 3

[0031] Use Zr, Hf, Ni and Sn element powders as raw materials, put them into a graphite crucible at a mass ratio of 0.5:0.5:1:1, then pack them into a sealed quartz tube (the tube is vacuumed), and put it into a temperature-controlled furnace During heating, heat preservation, and quenching, Zr 0.5 Hf 0.5 NiSn.

[0032] Take Zr 0.5 Hf 0.5 NiSn crystals are used as raw materials. First, the crystal material is broken into coarse particles smaller than 5 mm in a steel mold. Weigh 9-10 g of the sample and put it into a central cylinder together with a steel striker, and then fix it on a cryogenic grinder filled with liquid nitrogen. Set the pre-cooling time to 10 minutes, the frequency to 10 cps, the grinding time to 2 minutes, the re-cooling time to 3 minutes, and the cycle to 10. After 25 hours of freeze-grinding, samples were taken after the air was raised to room temperature, and then vacuum-dried to obtain nano-scale powder. The crystal form of the obtained powder is com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com