Novel alkaline hydrolysis tank and novel heating device and method for rare earth production

The technology of a heating device and a heating method is applied in the field of a new heating device and a new type of alkaline hydrolysis tank for heating and rare earth production, which can solve the problems of product price change, corrosion of the alkaline hydrolysis tank, paste pot or overflow pot, etc., so as to improve the decomposition rate and yield, reduce maintenance costs, and save production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

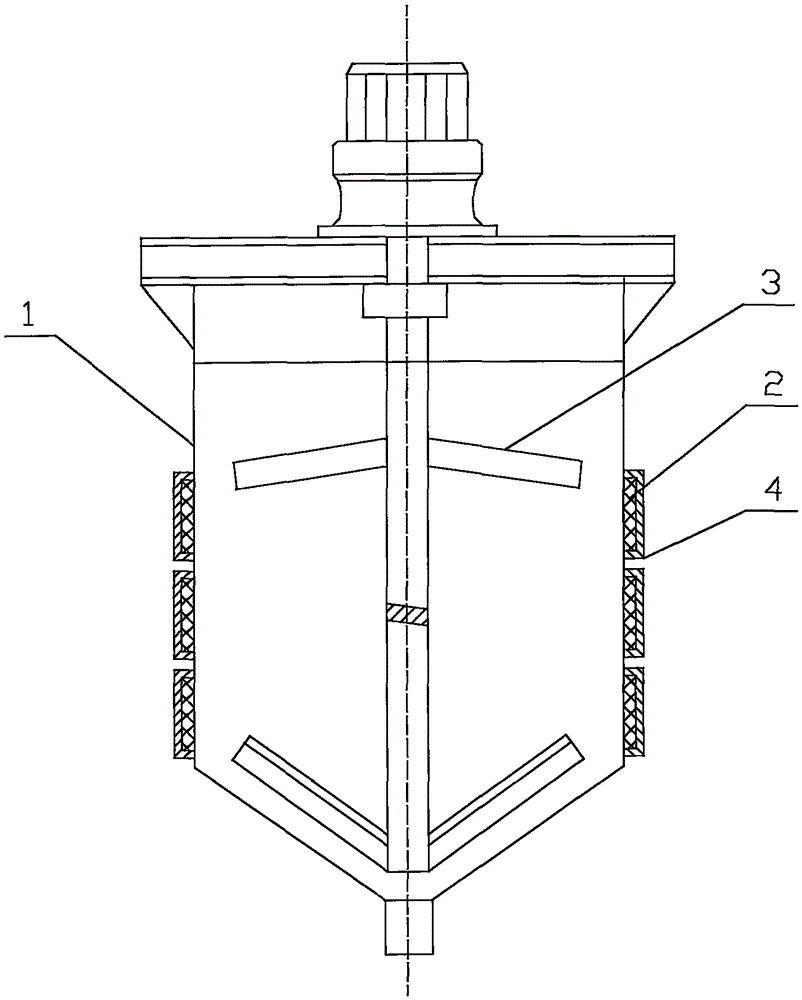

[0034] Embodiment 1: the novel alkaline hydrolysis tank that is used for rare earth production, it comprises alkali hydrolysis tank main body 1, is wrapped with ceramic heating sheet group on the outer wall of alkaline hydrolysis tank main body 1, and the inner surface of ceramic heating sheet group and alkali hydrolysis tank main body 1 The outer wall fits. The ceramic heating sheet group consists of 12 ceramic heating sheets 2, which are arranged in three layers from bottom to top. Each layer has 4 ceramic heating sheets 2. The power of each ceramic heating sheet 2 is 6 kilowatts. Alkaline hydrolysis tank main body 1 is arranged at equal intervals in the circumferential direction. The main body 1 of the alkaline hydrolysis tank is provided with a stirring paddle 3 with three layers of blades. The outer surface of each ceramic heating sheet 2 is coated with a gypsum module 4 . The ceramic heating plate 2 is installed independently, and the outside of the ceramic heating pla...

Embodiment 2

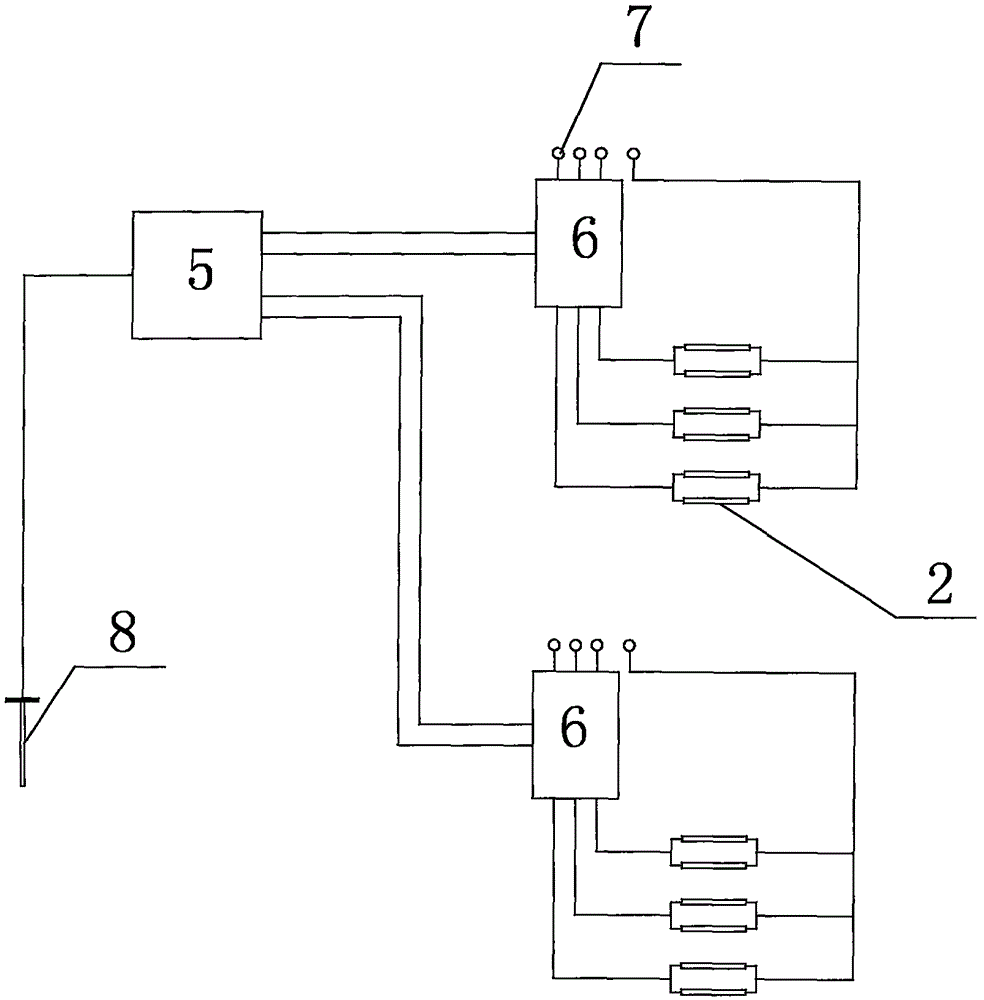

[0035] Embodiment 2: A novel heating device for rare earth production, which includes an alkaline solution tank main body 1, a PID temperature controller 5, a thyristor voltage regulator 6, a power supply 7 and a thermocouple 8; the outer wall of the alkaline solution tank main body 1 A ceramic heating sheet group is wrapped on the top, and the inner surface of the ceramic heating sheet group is attached to the outer wall of the main body 1 of the alkaline hydrolysis tank. The ceramic heating sheet group consists of 18 ceramic heating sheets 2, which are arranged in three layers from bottom to top, with 6 ceramic heating sheets 2 in each layer, and the power of each ceramic heating sheet 2 is 4 kilowatts. Alkaline hydrolysis tank main body 1 is arranged at equal intervals in the circumferential direction. The main body 1 of the alkaline hydrolysis tank is provided with a stirring paddle 3 with three layers of blades. The outer surface of each ceramic heating sheet 2 is coated...

Embodiment 3

[0036] Embodiment 3: a novel heating method for rare earth production, which includes the following steps: (1) equipment preparation and connection; (2) setting temperature control program heating; wherein,

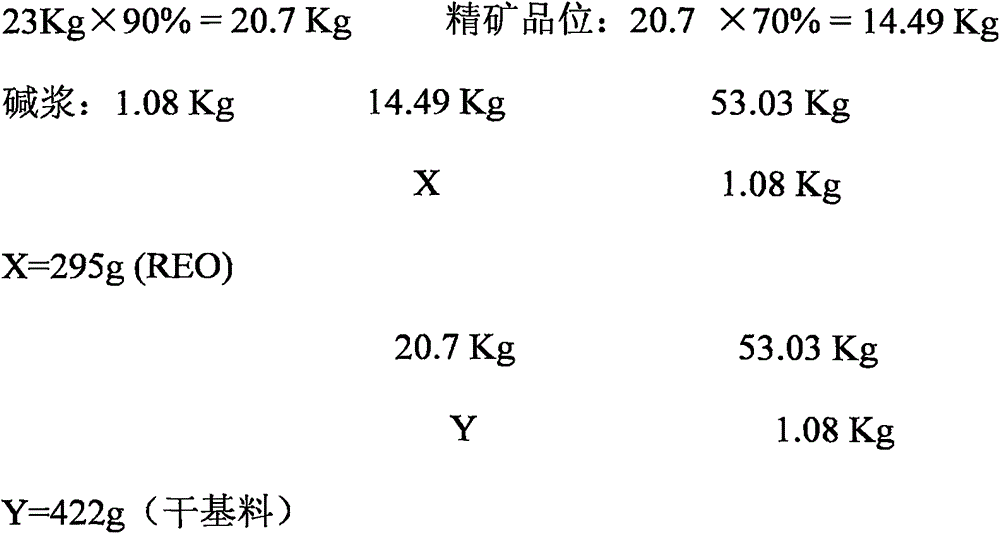

[0037] (1) Equipment preparation and connection: The outer wall of the main body 1 of the alkaline hydrolysis tank is wrapped with a ceramic heating sheet group, and the inner surface of the ceramic heating sheet group is bonded to the outer wall of the main body 1 of the alkaline hydrolysis tank. The ceramic heating sheet group consists of 15 ceramic heating sheets 2, which are arranged in three layers from bottom to top, with 5 ceramic heating sheets 2 in each layer, and the power of each ceramic heating sheet 2 is 5 kilowatts. Alkaline hydrolysis tank main body 1 is arranged at equal intervals in the circumferential direction. The main body 1 of the alkaline hydrolysis tank is provided with a stirring paddle 3 with three layers of blades. The outer surface of each cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com