Rare-earth-based lubricating grease and preparation method thereof

A grease, rare earth-based technology, applied in the field of rare-earth-based grease and its preparation, can solve the problems of complex composition and cannot be realized by one-step reaction, and achieve the advantages of reducing friction, excellent lubricating effect and anti-corrosion effect, and reducing production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] According to a preferred embodiment of the present invention, the method includes: mixing and heating the organic acid and a part of the base oil to 50-90°C to dissolve the organic acid, and then adding the rare earth element precursor dissolved in another part of the base oil; stirring After uniformity, raise the temperature to 80-100°C for a full reaction for 0.5-2 hours, then raise the temperature to 120-140°C for dehydration; then add the remaining base oil and refine at 180-220°C for 5-30 minutes, and wait for it to cool down to 60-120°C Add optional additives at around ℃; finally cool to room temperature, grind and homogenize to obtain rare earth base grease. Wherein, the sum of the amount of a part of base oil, another part of base oil and the remaining base oil is the total amount of base oil used. In the present invention, the weight ratio of the three is preferably 1:0.1-2:0.5-3 .

[0046] The present invention also provides the rare earth-based lubricating g...

Embodiment 1

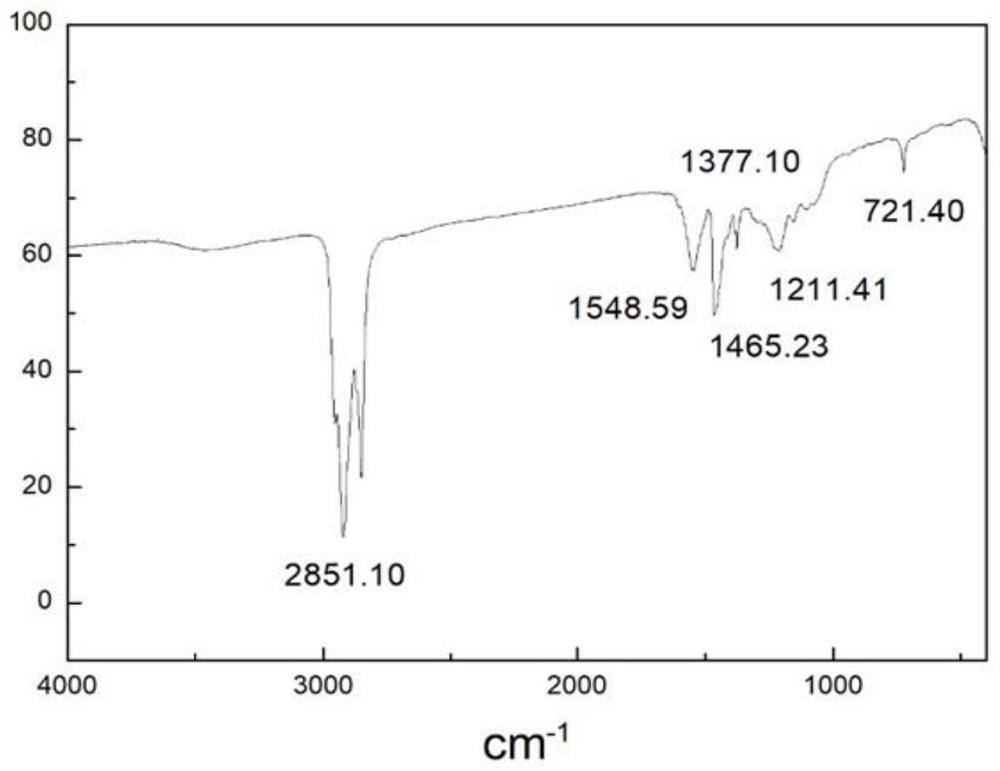

[0049] Add 200g of 150BS quenching oil (the kinematic viscosity at 100°C is 31mm 2 / s, purchased from Karamay Petrochemical Company, hereinafter the same), add 43.45g of 12-hydroxystearic acid, heat to 60°C, this is solution 1. Add 9.15g of lanthanum hydroxide to 100g of 150BS base oil, raise the temperature to 60°C and slowly add to the above solution 1. After stirring evenly, raise the temperature to 100°C to fully react for 1 hour, then raise the temperature to 140°C to remove water, and then raise the temperature to 200°C for refining for 10 minutes. Finally, add 150g of 150BS quenching oil, cool to 110°C, add 10g of diphenylamine and 10g of barium petroleum sulfonate, grind and homogenize, and obtain rare earth lanthanum-based grease, whose infrared spectrum is shown in figure 1 ,from figure 1 As can be seen in the 1548cm -1 There is an absorption peak at , indicating that lanthanum exists in the form of fatty acid lanthanum.

Embodiment 2

[0051] Add 43.13g of stearic acid to 200g of 150BS quenching oil, heat to 60°C, this is solution 1. Add 9.6g of lanthanum hydroxide to 100g of 150BS base oil, raise the temperature to 60°C and slowly add to the above solution 1. After stirring evenly, raise the temperature to 100°C for full reaction for 1 hour, then raise the temperature to 140°C to remove water, and then raise the temperature to 200°C for refining for 10 minutes. Finally, add 150g of 150BS quenching oil, cool to 90°C, add 10g of 2,6-di-tert-butyl-p-cresol and 10g of dodecenylsuccinic acid, grind and homogenize to obtain rare earth lanthanum-based grease, and its infrared spectrum and figure 1 Similar, at 1548cm -1 has an absorption peak.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com