Preparation method of low-cost ultra-large and ultra-thick carbon/carbon composite material

A carbon composite material, low-cost technology, applied in the field of preparation of low-cost ultra-large and ultra-thick carbon/carbon composite materials, can solve the problems of large-scale production process control difficulty, high scrap rate, product deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

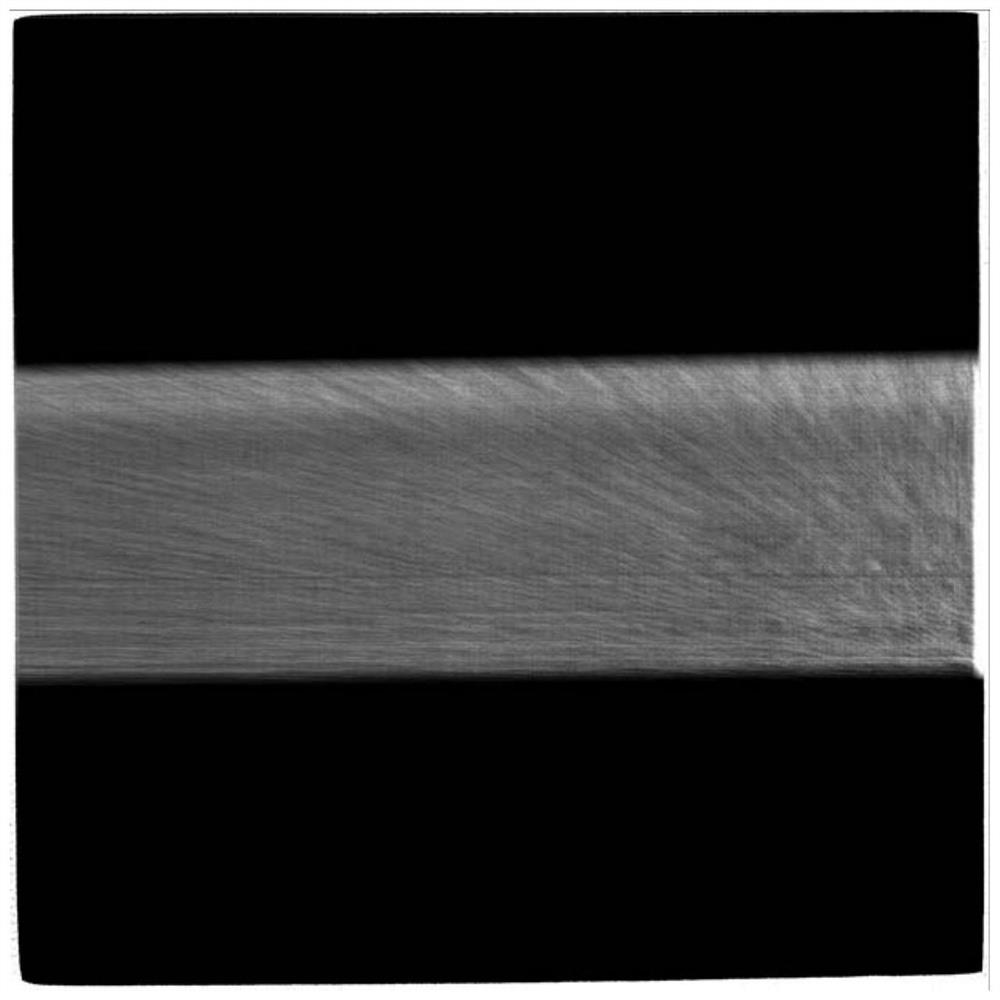

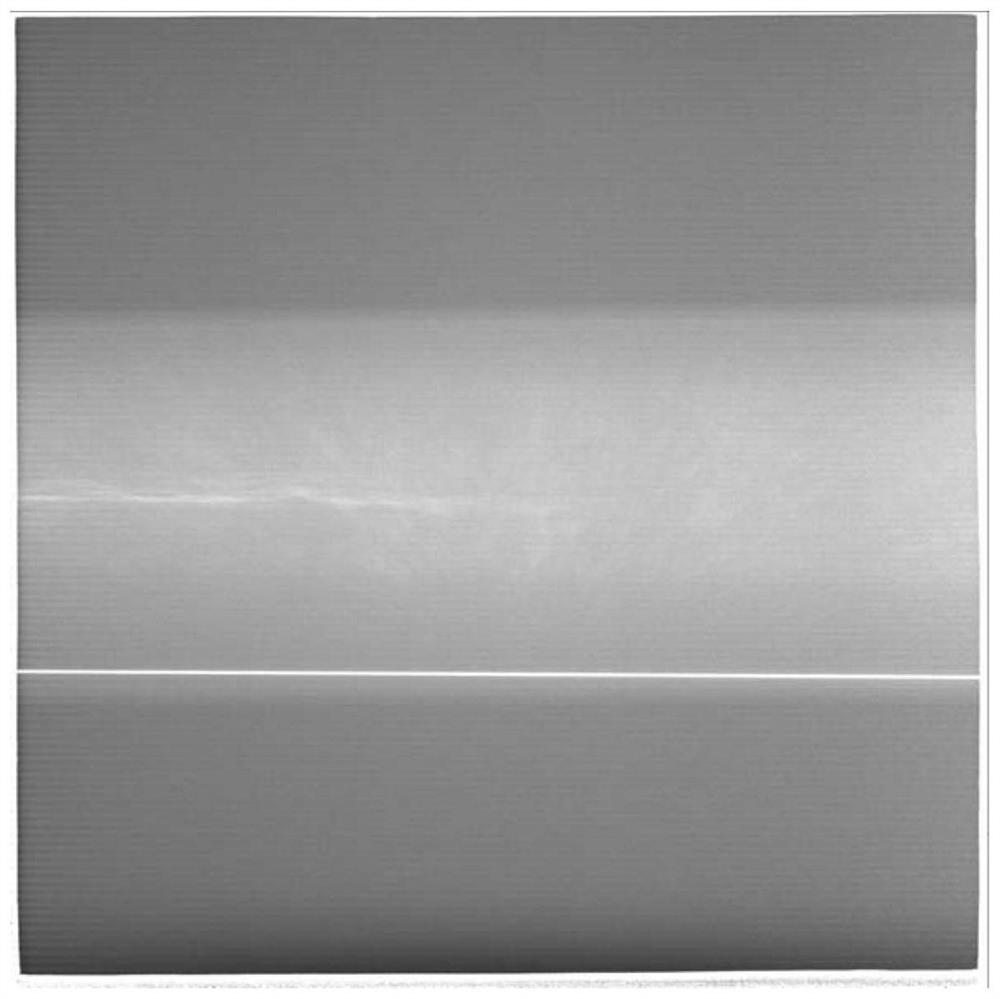

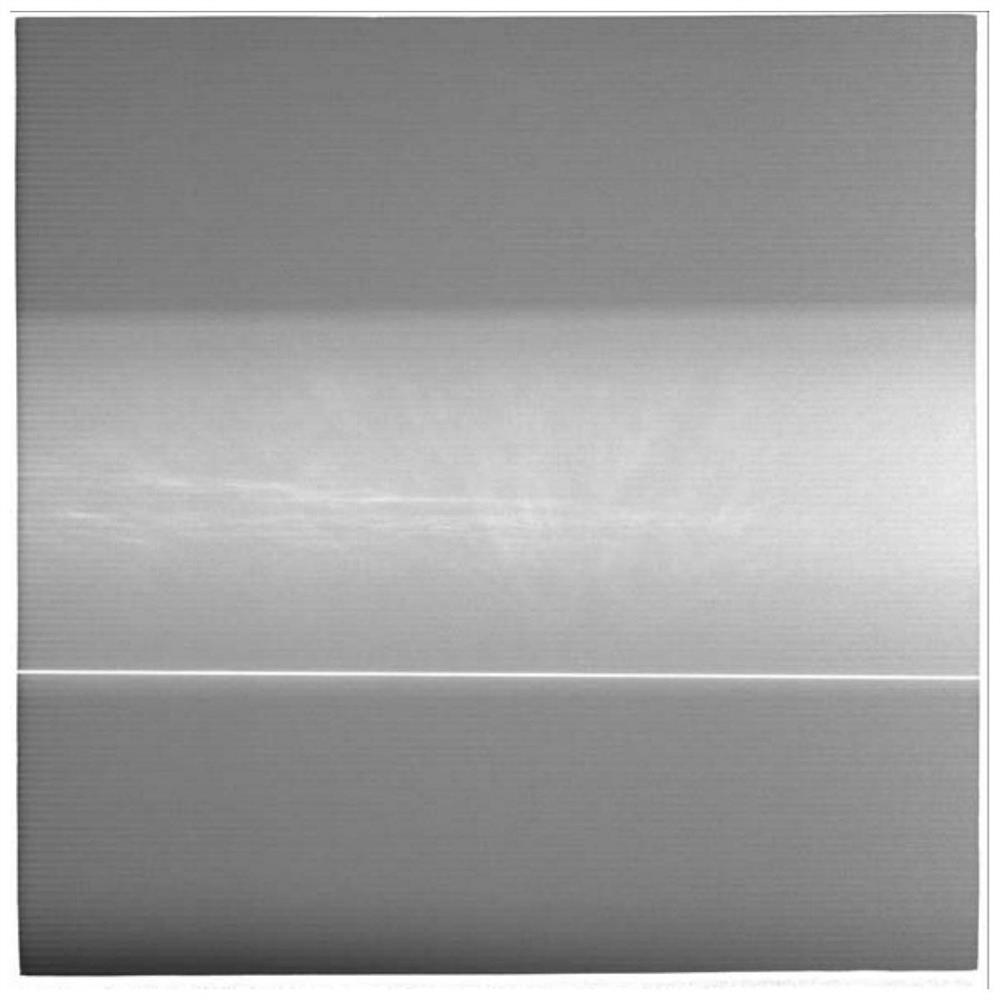

Image

Examples

Embodiment 1

[0040] a. Prepare 20 carbon fiber prefabricated bodies. The carbon fiber prefabricated body is a 2D needle-punched structure. A layer of PANCF non-weft cloth and a layer of PANCF non-weft cloth mesh are alternately laid, and the non-weft cloth is alternately laid at 0° / 90°. Made by continuous needle punching; the size of the carbon fiber preform is 1380mm×400mm×200mm, and the density is 0.38g / cm 3 ;

[0041] b. Graphitize the carbon fiber prefabricated body to obtain a carbon fiber green body; put the carbon fiber prefabricated body into a heat treatment furnace, first evacuate, raise the temperature to 2000°C and keep it warm for 2 hours, during which argon gas is filled, and the furnace pressure is 0.2-3KPa, Graphitize the carbon fiber preform, and then cool it naturally with the furnace;

[0042] c. Carry out impregnation and curing treatment, carbonization treatment, high temperature heat treatment and mechanical processing on the carbon fiber green body in sequence;

[...

Embodiment 2

[0051] a. Prepare 40 carbon fiber prefabricated bodies. The carbon fiber prefabricated body is a 2D needle-punched structure. A layer of PANCF non-weft cloth and a layer of PANCF non-weft cloth mesh are alternately laid, and the non-weft cloth is alternately laid at 0° / 90°. Continuous needle punching; the size of the carbon fiber preform is 1250mm×350mm×180mm, and the density is 0.45g / cm 3 ;

[0052] b. Graphitize the carbon fiber prefabricated body to obtain a carbon fiber green body; put the carbon fiber prefabricated body into a heat treatment furnace, first evacuate, raise the temperature to 2000°C and keep it warm for 2 hours, during which argon gas is filled, and the furnace pressure is 0.2-3KPa, Graphitize the carbon fiber preform, and then cool it naturally with the furnace;

[0053] c. Carry out impregnation and curing treatment, carbonization treatment, high temperature heat treatment and mechanical processing on the carbon fiber green body in sequence;

[0054] Fu...

Embodiment 3

[0062] a. Prepare 60 pieces of carbon fiber prefabricated body. The carbon fiber prefabricated body is a 2D needle-punched structure. A layer of PANCF non-weft cloth and a layer of PANCF non-weft cloth mesh tire are alternately laid, and the non-weft cloth is alternately laid at 0° / 90°. It is made by continuous needle punching; the size of the carbon fiber preform is 1020mm×310mm×160mm, and the volume density of the felt body is 0.50g / cm 3 ;

[0063] b. Graphitize the carbon fiber prefabricated body to obtain a carbon fiber green body; put the carbon fiber prefabricated body into a heat treatment furnace, first evacuate, raise the temperature to 2000°C and keep it warm for 2 hours, during which argon gas is filled, and the furnace pressure is 0.2-3KPa, Graphitize the carbon fiber preform, and then cool it naturally with the furnace;

[0064] c. Carry out impregnation and curing treatment, carbonization treatment, high temperature heat treatment and mechanical processing on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com