Permanent circular working well with preset pipe-jacking door opening in water-rich formation and construction method of permanent circular working well

A technology for circular working and water-rich formations, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of piping quicksand and surrounding subsidence, difficult operation, and long time-consuming, so as to overcome construction difficulties and ensure safety Risk, save capital investment, advanced technical concept effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

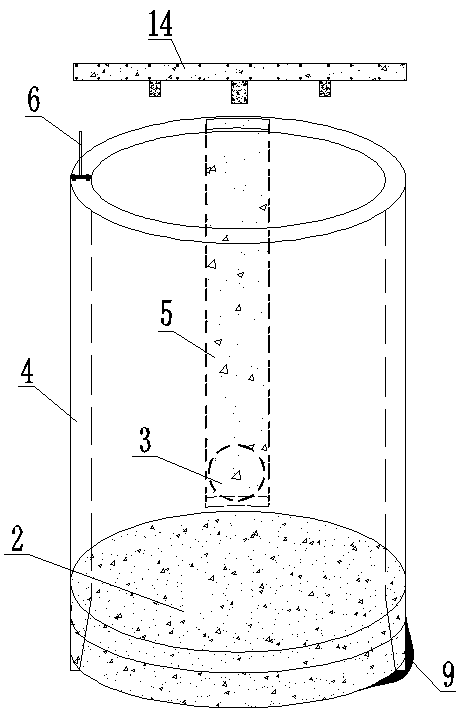

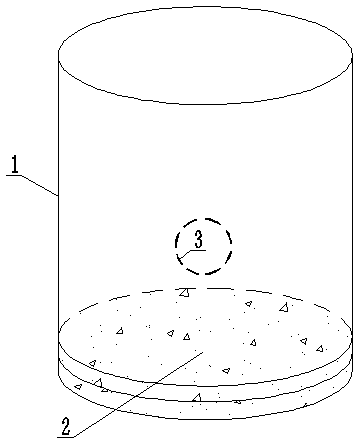

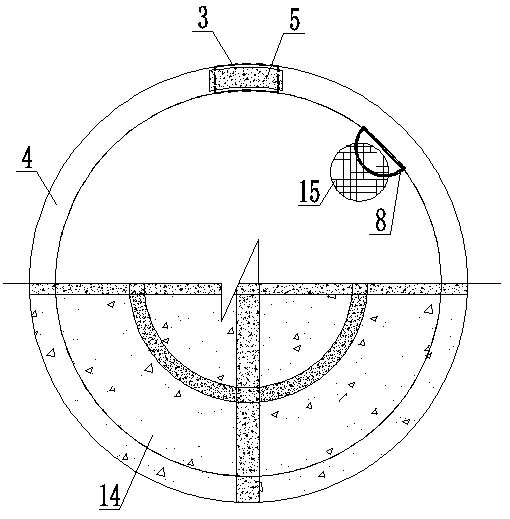

[0045] A construction method for a permanent circular working well with preset pipe jacking openings in water-rich formations. Firstly, the functional requirement design of the circular working well is completed; then the maintenance structure and temporary protection construction are carried out in sequence; Earthwork excavation, bottom sealing of the circular working well; installation of ladders entering the circular working well, joint leakage control, and installation of water-stop pressure plates at the opening; then the hydraulic thrust of the pipe jacking equipment penetrates and lifts the sandwich concrete slab wall and forms The thin-walled plain concrete cavity opens the door opening; after the relevant operations in the well are completed, the top cover plate of the circular working well, the inspection well installation and waterproof construction can complete the construction of the permanent circular working well with the preset pipe jacking door opening in the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com