Disc type composite single-pile fan foundation suitable for soft soil seabed and construction method

A wind turbine foundation and soft soil technology, applied in soil protection, foundation structure engineering, construction, etc., can solve the problems of lack of safe and reliable foundation technology, limit the application range of single piles, difficulties in manufacturing and construction, etc., and achieve an excellent level of resistance And the effect of anti-bending and deformation performance, saving the offshore window period, and reducing the difficulty of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make those skilled in the art more clearly understand the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

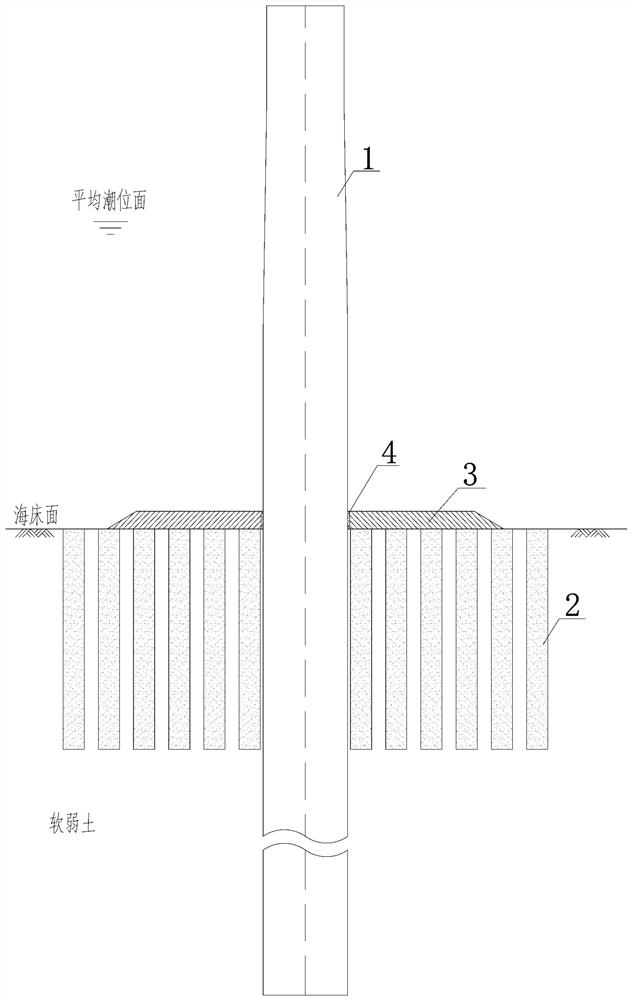

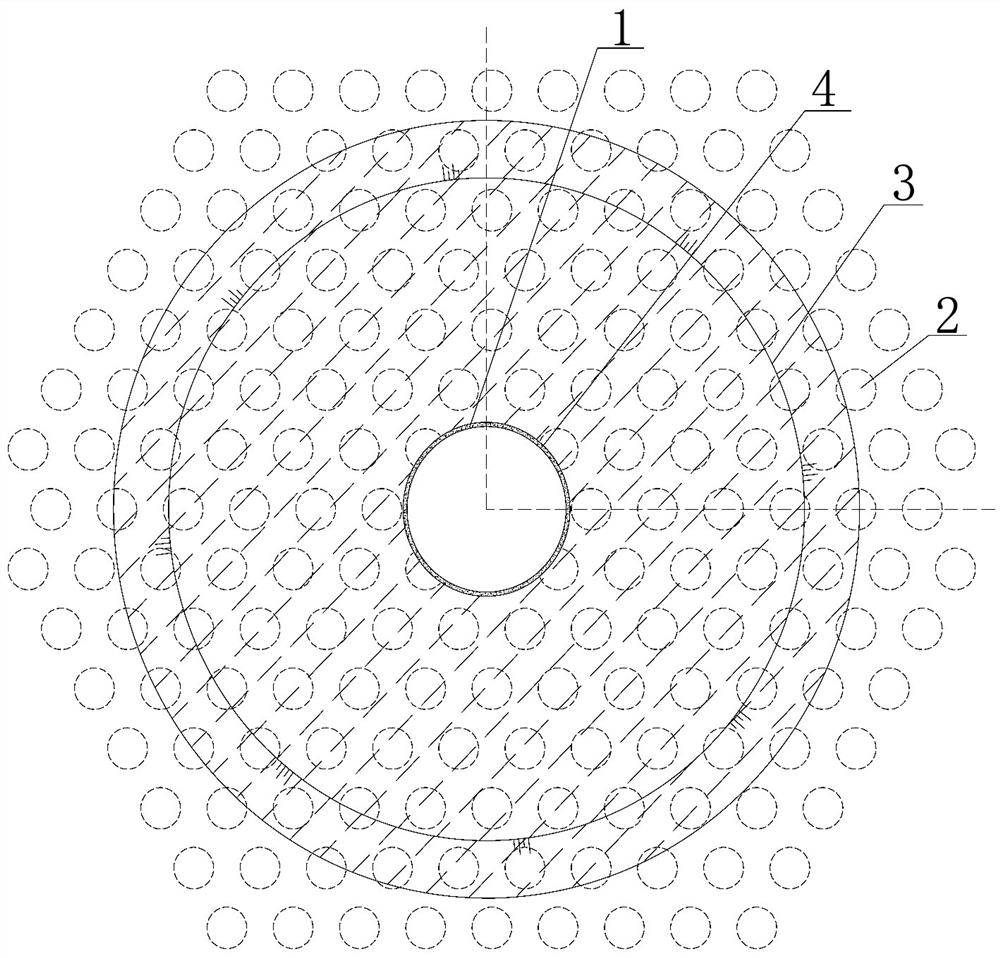

[0023] Such as Figure 1-2 As shown, a disc-type composite single-pile fan foundation suitable for soft soil seabed according to the present invention mainly includes a central large-diameter single pile that is sunk into the soft soil and arranged around the central large-diameter single pile and used for Compacted sand piles for shallow foundation reinforcement. The compacted sand piles are arranged in soft soil within a certain width and depth around the pile of the central large-diameter single pile, and the pile sinking depth of the central large-diameter single pile is greater than that of the compacted sand pile. The pile sinking depth of the sand pile, the compacted sand pile around the central large-diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com