Steam Generator Used in Petroleum Heavy Oil Exploitation

A technology of steam generator and heavy oil, applied in the field of heavy oil production, can solve the problems of difficulty in adapting to the dispersed operation of oil wells, long injection steam cycle, long production cycle, etc., so as to prevent scale clogging of equipment, affecting the normal operation of equipment or even scrapping the steam. The effect of short injection time and fast combustion reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

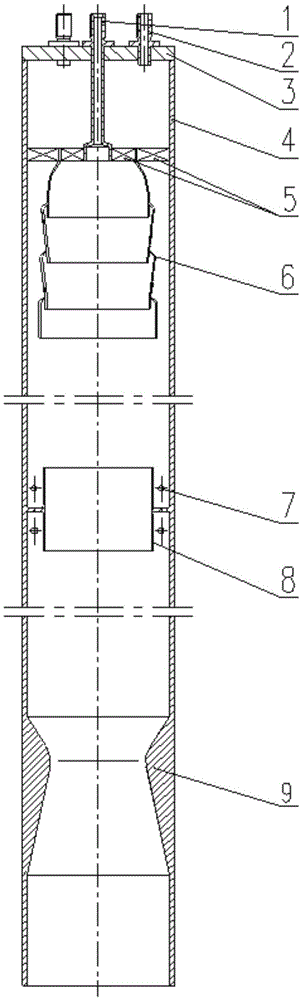

[0029] The structure of the steam generator used in this embodiment for petroleum heavy oil exploitation is as attached figure 1 As shown, it includes a cylindrical shell 4 as the shell of the steam generator, and an end cover 3 designed with a gas inlet joint 1 and a pressure air intake joint 2 is fixed on the air inlet end of the cylindrical shell 4. A double-ring cyclone 5, a flame cylinder 6, a water film generator and an evaporative converter 9 are arranged coaxially in sequence along the direction of gas flow in the body. The gas inlet connecting pipe 1 is arranged at the center of the end cover 3, and four pressure air inlet connecting pipes 2 are designed, which are evenly distributed on the circumference around the gas inlet connecting pipe. The cyclone is a double-ring cyclone composed of an inner cyclone and an outer cyclone. The flame tube 6 is composed of a funnel-shaped tube section as the head of the flame tube, 3 conical tube sections with interfaces as the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com