Constant current control circuit controlling charging loop current

A constant current control circuit and charging circuit technology, which is applied to battery circuit devices, circuit devices, control/regulation systems, etc., can solve problems such as lower energy conversion efficiency, unreliable circuit operation, and large circuit heat generation, so as to eliminate eddy current loss Effects of heat, prevention of reverse voltage breakdown switch tube, volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

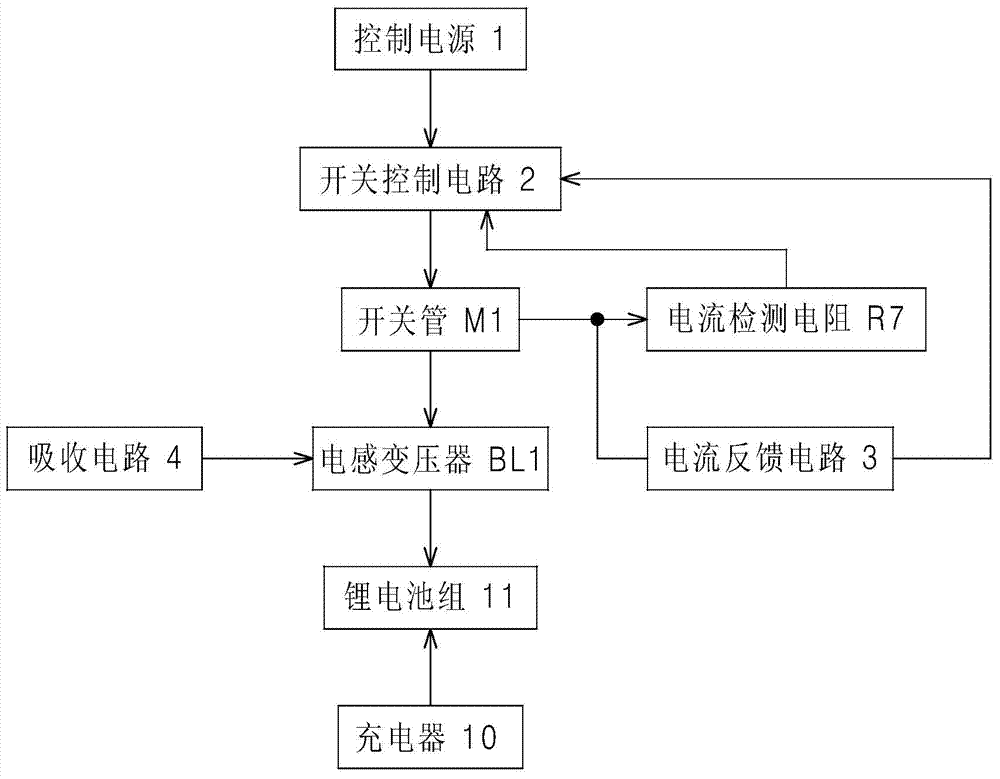

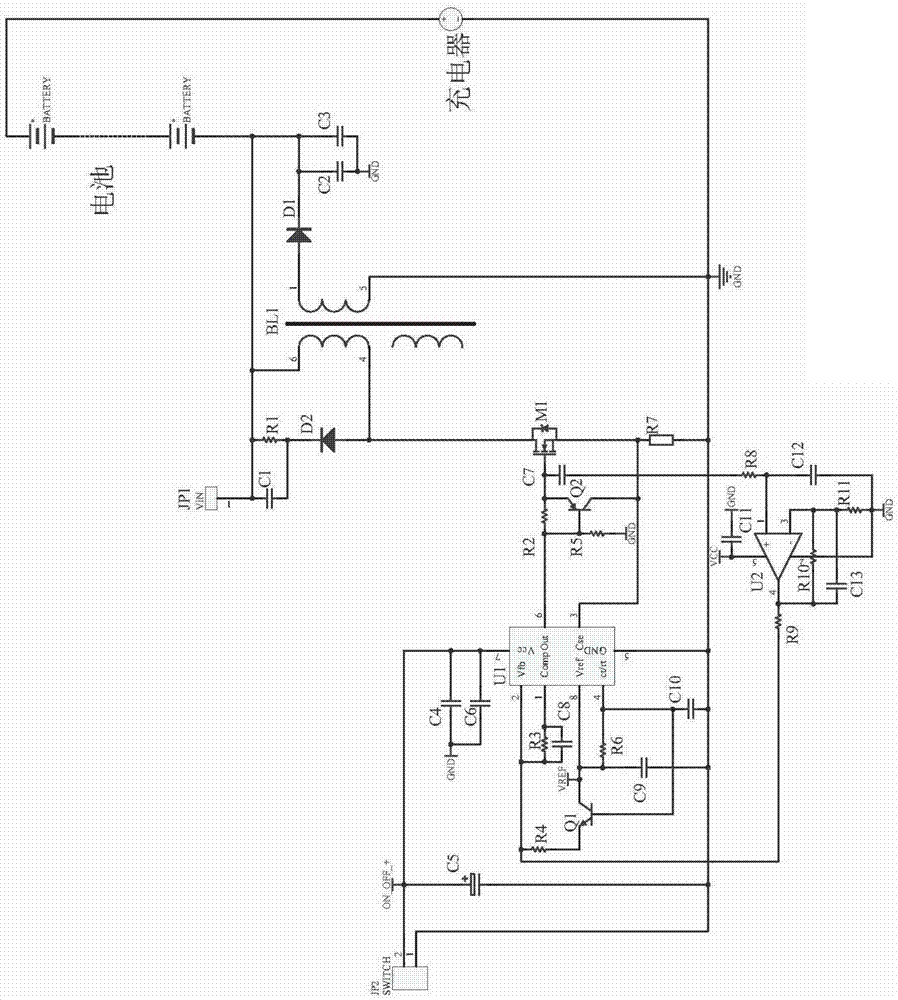

[0014] Such as figure 1 , figure 2 As shown, the constant current control circuit for controlling the charging circuit current according to the present invention includes a current feedback circuit 3, a snubber circuit 4 connected in series by a snubber resistor R1 and a snubber diode D2, a switch tube M1, and a PWM-based control chip U1 (UC3842) The switch control circuit 2 that controls the switching of the switch tube M1 and the inductance transformer BL1. One end of the primary coil of the inductance transformer BL1 is connected to the output terminal (drain) of the switch tube M1, and the other end of the primary coil of the inductance transformer BL1 is used as The access terminal JP1 connected to the charging circuit for charging the lithium battery pack 11 by the charger 10, the absorbing circuit 4 is connected in parallel to the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com