Shock wave generating device of oil-gas wells and oil-gas well yield increasing method adopting shock waves

A generating device and technology for oil and gas wells, applied in wellbore/well components, earthwork drilling, production fluid, etc., can solve the problems of long pulse discharge circuit, poor reliability, large energy loss, etc., and achieve energy utilization rate High, simple and reliable structure, the effect of eliminating heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

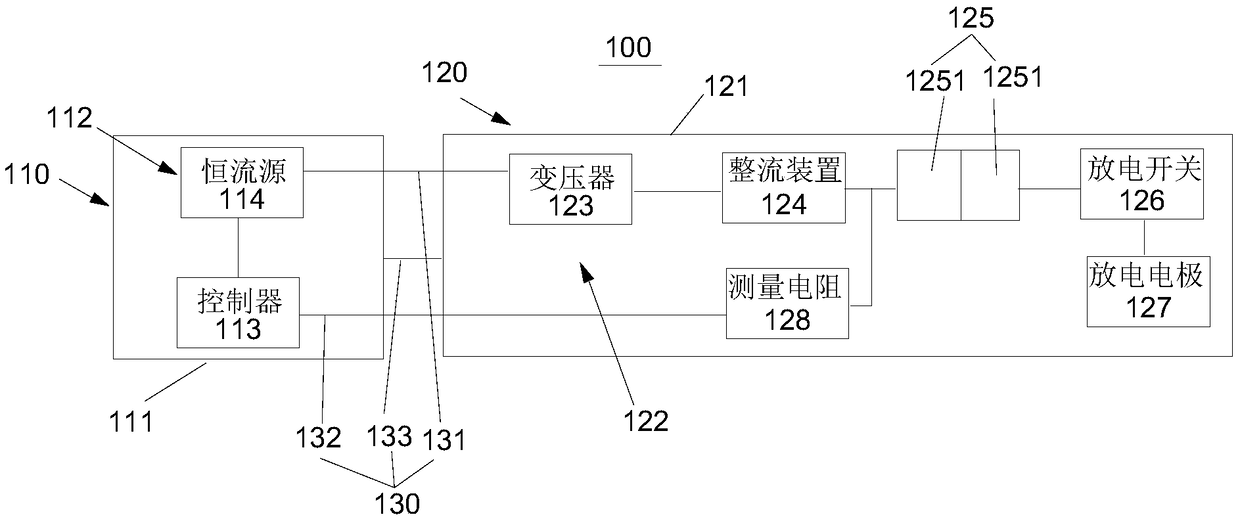

[0046] refer to figure 1 This embodiment provides a shock wave generator 100 for an oil and gas well. The shock wave generator 100 mainly includes a surface component 110 and a downhole component 120 , and the downhole component 120 is controlled by the ground component 110 to generate shock waves.

[0047] refer to figure 1 , the ground component 110 includes a fixed platform 111 and a ground device 112; the ground device 112 is fixedly installed in the fixed platform 111, and the fixed platform 111 provides a fixed and solid working environment for the ground device 112.

[0048]The ground device 112 includes a controller 113 and a constant current source 114; the controller 113 has functions of an integral power switch, voltage detection and emergency power-off. The controller 113 includes a processor, which may be an integrated circuit chip and has a signal processing capability. The above-mentioned processor can be a general processor, including a central processing uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com