Refrigerating method using gas hydrate as medium and air conditioner refrigerator

A technology of gas hydrate and refrigeration method, applied in refrigerators, refrigeration and liquefaction, chemical instruments and methods, etc., can solve problems such as no mature products, and achieve the effect of great development and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

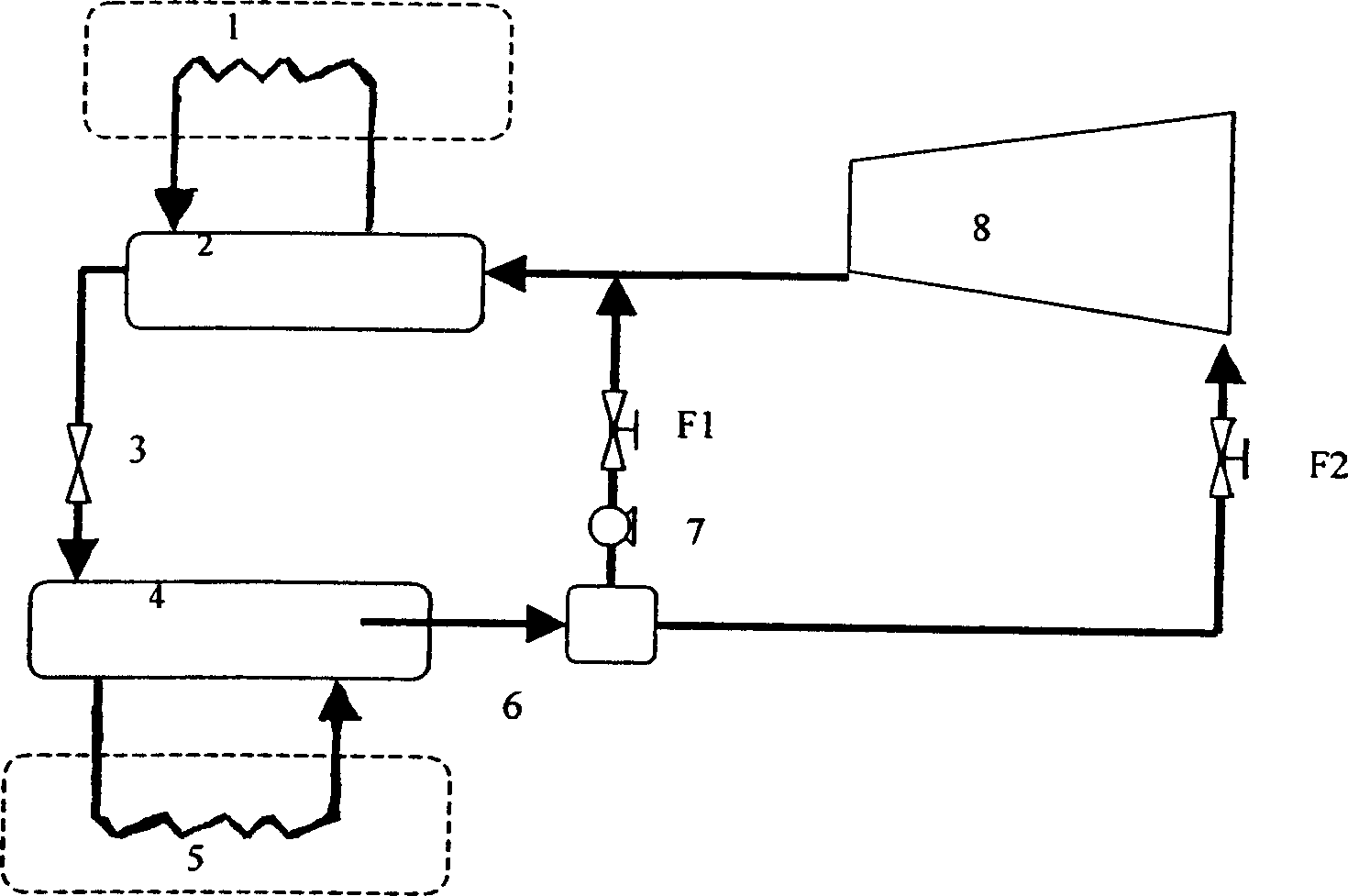

[0033] as attached figure 1As shown, the hydrate refrigeration system 12 is composed of a decomposition reactor (evaporator) 4, an expansion valve 3, a compressor 8, a formation reactor (condenser) 2, a gas-liquid separator 6, and a water pump 7. The decomposition reactor (evaporator) 4, the expansion valve 3, the compressor 8, the generation reactor (condenser) 2, the gas-liquid separator 6 and the water pump 7 are connected through pipelines, and the pipelines are equipped with hydrate refrigerant. The decomposition reactor (evaporator) 4 is directly connected to the cold end 5 for cooling. The generating reactor (condenser) 2 is directly connected to the hot end 1 to release heat to the outside. During operation, the compressor 8 compresses the gas to generate high-pressure gas, and the high-pressure gas reacts with water in the generating reactor (condenser) 2 to generate gas hydrate and release heat. Reactor (evaporator) 4, the hydrate is decomposed into gas and water ...

Embodiment 2

[0037] as attached figure 1 As shown, the hydrate refrigeration system 12 is composed of a decomposition reactor (evaporator) 4, an expansion valve 3, a compressor 8, a formation reactor (condenser) 2, a gas-liquid separator 6, and a water pump 7. The decomposition reactor (evaporator) 4, the expansion valve 3, the compressor 8, the generation reactor (condenser) 2, the gas-liquid separator 6 and the water pump 7 are connected through pipelines, and the pipelines are equipped with hydrate refrigerant. The decomposition reactor (evaporator) 4 is directly connected to the cold end 5 for cooling. The generating reactor (condenser) 2 is directly connected to the hot end 1 to release heat to the outside. During operation, the compressor 8 compresses the gas to generate high-pressure gas, and the high-pressure gas reacts with water in the generating reactor (condenser) 2 to generate gas hydrate and release heat. Reactor (evaporator) 4, the hydrate is decomposed into gas and water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com