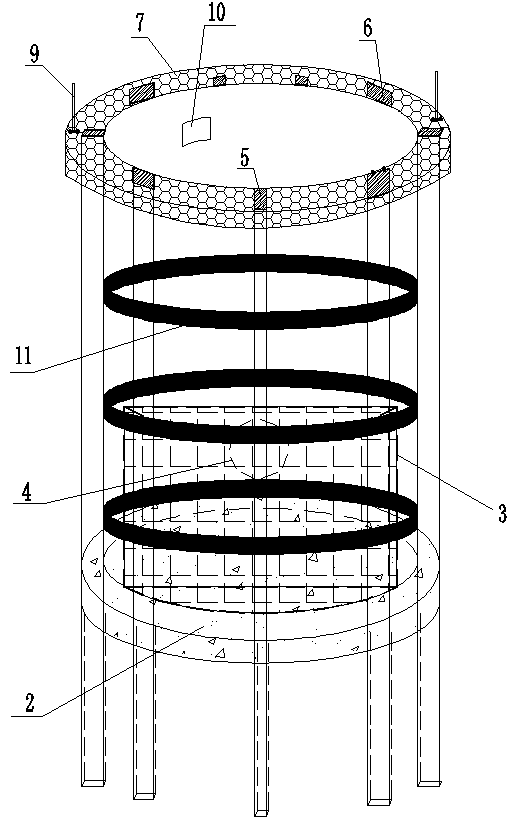

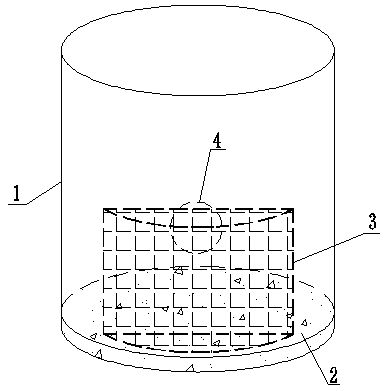

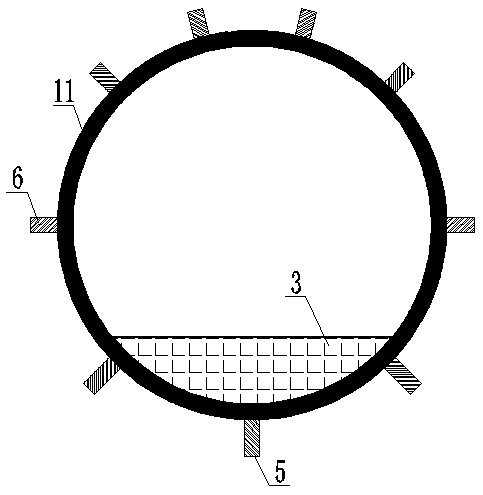

Rear-leaning-wall-integrated assembly type recoverable round working well and construction method thereof

A technology of circular work and construction method, applied in excavation, artificial islands, water conservancy projects, etc., can solve problems such as long construction period, high cost, and difficulty in sinking, and achieve the effect of exerting mechanical properties, ensuring functions, and shortening construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]A construction method for a prefabricated recyclable circular working well with an integrated rear wall. First, the functional requirements design of the circular pipe-jacking working well is completed; then the construction of support piles, the installation of prefabricated crown beams, and the construction of edge protection are carried out in sequence. ; Then carry out the earthwork excavation of the circular pipe jacking work well, the alternate construction of the soil retaining panel and the annular inner support beam; install the ladder and the bottom seal of the work well into the circular work well, and then carry out the back-to-wall construction to complete the assembly The integrated construction of the recyclable circular pipe jacking working well and the back wall; after the operation in the well is completed, the back wall, soil retaining panel, annular inner support beam, crown beam and support piles are gradually recovered during the backfill process Wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com