Design and construction method for flexible composite, seepage-proofing, fabricated and recyclable row pile supporting structure with circular cross section

A composite anti-seepage and support structure technology, applied in foundation structure engineering, excavation, sheet pile walls, etc., to achieve the effect of advanced technology, safe and reliable structure, and perfect material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

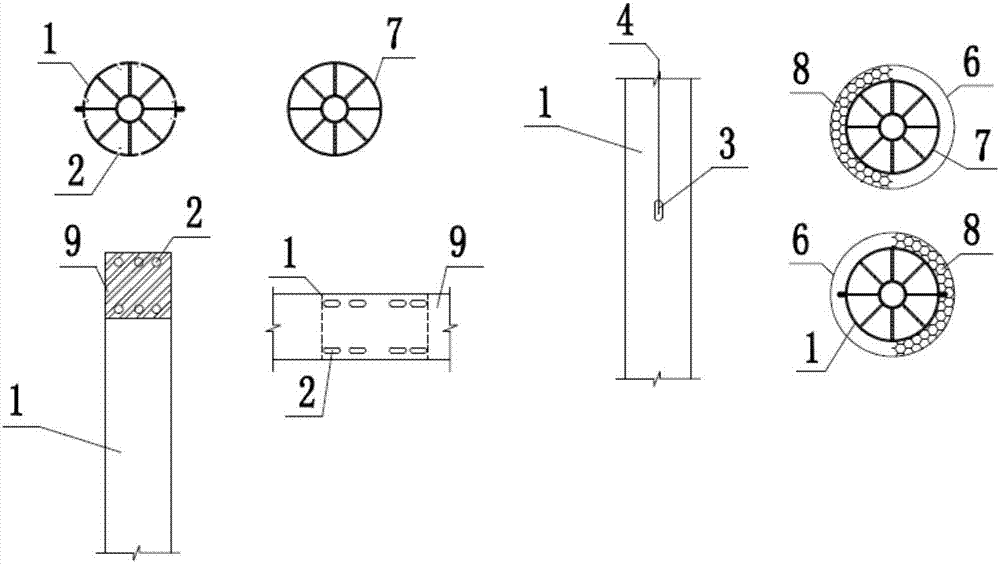

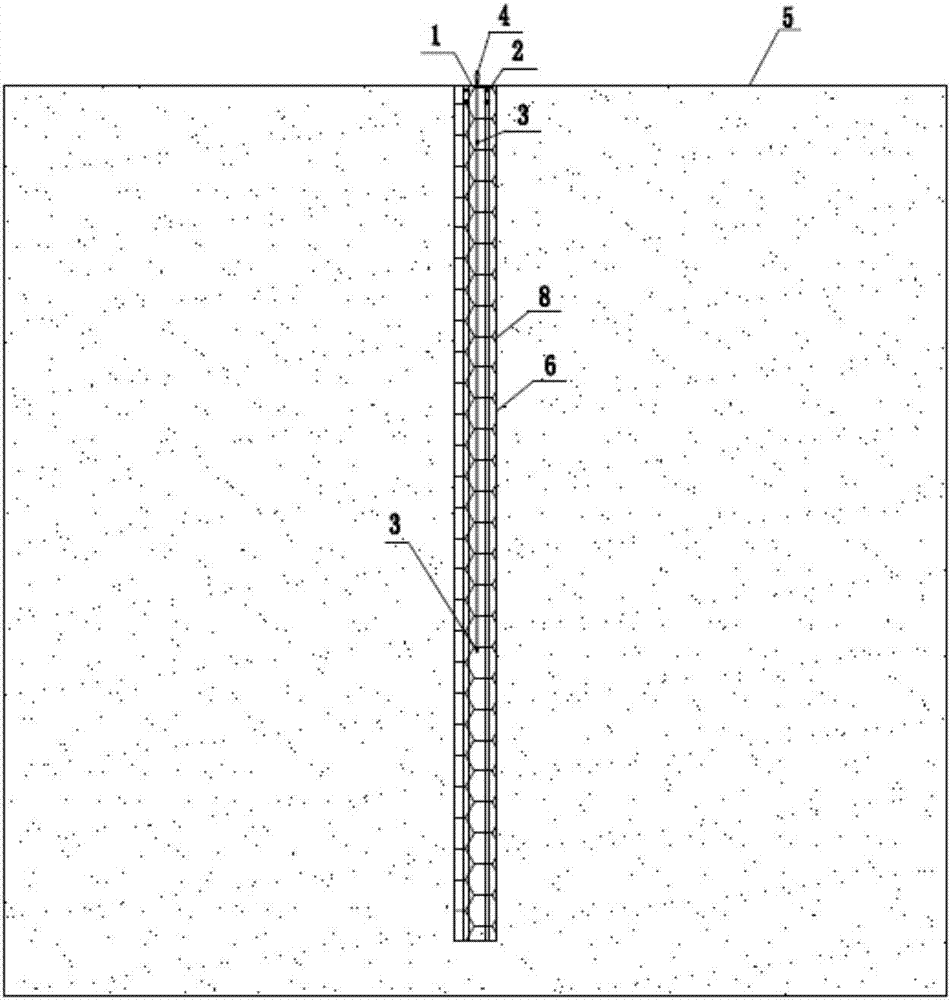

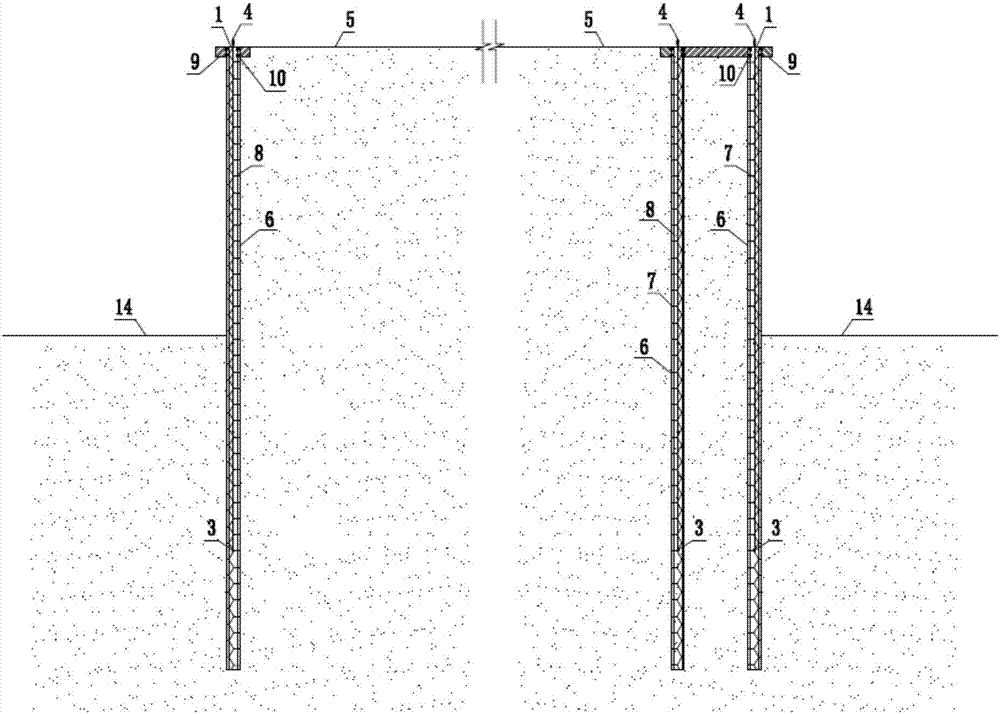

[0049] The present invention will be further described below in conjunction with accompanying drawing.

[0050] A method for the design and construction of a flexible composite anti-seepage assembled recyclable circular section row pile support structure, characterized in that, in the design of foundation pit support structure, starting from the essence of foundation pit engineering, the design of building flexible composite is proposed for the first time concept, and introduce the idea of mechanical precision manufacturing and on-site assembly standardized production. After completing the design work according to relevant materials, the factory prefabricated and processed the required support components, and then carried out the on-site assembly construction of the support structure and the backfilling of the foundation pit. The protective structure is dismantled and recycled simultaneously, and can be reused and standardized design and construction. The construction proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com