Preparation method of core-shell structural perovskite quantum dot

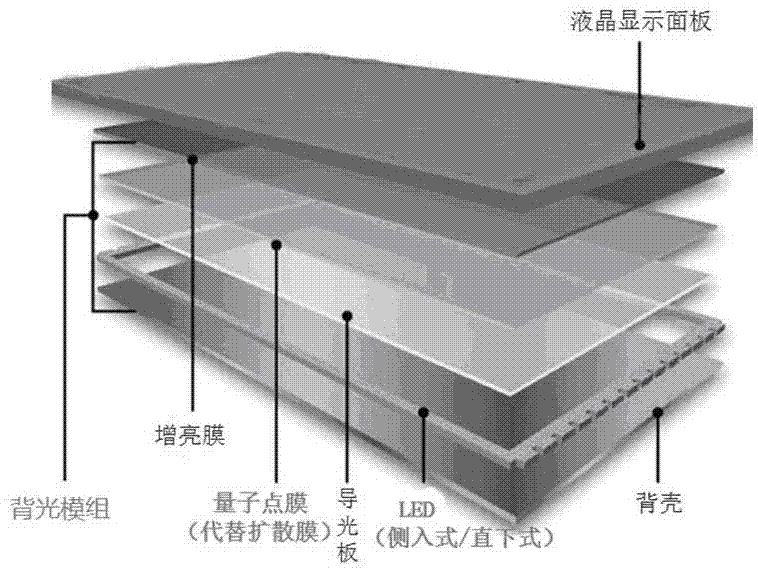

A core-shell structure, perovskite technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of polar solvent sensitivity, fluorescence quenching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

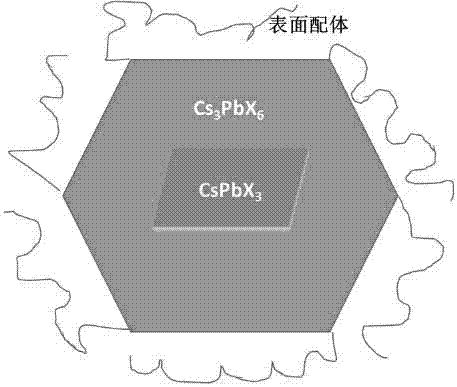

[0032] CsPbBr3 / Cs4PbBr6 core-shell structure perovskite quantum dot materials with surface ligands

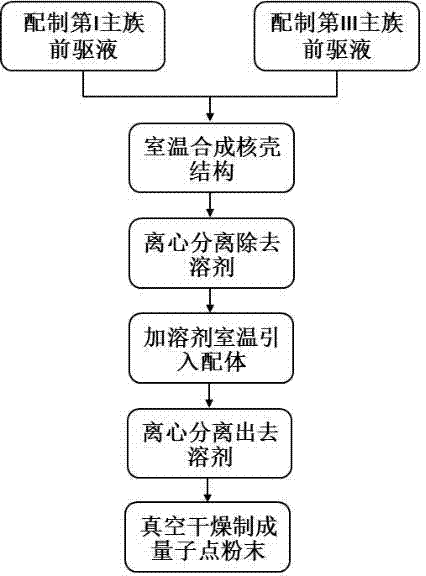

[0033] This example synthesizes a CsPbBr3 / Cs4PbBr6 core-shell perovskite material with a stimulated emission peak at 515 nm and surface ligands. The details are as follows: First, the preparation of the precursor of the main group I. Add 0.3 parts by mass of CsBr white powder to 0.5 parts by mass of distilled water, shake and mix to dissolve. Second, the preparation of the Group III precursor. Add 0.2 parts by mass of PbBr white powder to 2.0 parts by mass of N,N-dimethylformamide, shake and mix to dissolve. Then, add the precursor solution of the main group I to the precursor solution of the main group III dropwise, oscillate and mix evenly for each drop. At the end of the reaction, a precipitate was generated, and a fluorescent mixed solution was obtained, which was excited by a 455nm blue light source ( Figure 4 ) shows an emission wavelength of 515 nm and a half-maximu...

Embodiment 2

[0044] CsPbBr with surface ligands x I 3-x / Cs 4 PbBr x I 3-x Core-shell perovskite quantum dots

[0045] This example synthesizes CsPbBr with a surface ligand at 640 nm with a stimulated emission peak x I 3-x / Cs 4 PbBr x I 3-x Core-shell structure perovskite quantum dots. The details are as follows: First, the preparation of the precursor of the main group I. Add 0.5 parts by mass of CsBr white powder to 0.5 parts by mass of distilled water, shake and mix to dissolve. Second, the preparation of the Group III precursor. Add 0.25 parts by mass of PbI yellow powder to 2.0 parts by mass of dimethyl sulfoxide, shake and mix to dissolve. Then, add the Group I precursor solution dropwise to the Group III precursor solution, and shake and mix evenly for each drop until a red suspension is formed. Next, centrifuge the suspension at 8000 rpm, remove the supernatant, add 2 parts by mass of toluene, 0.1 part by mass of oleylamine, and 0.01 part by mass of oleic acid, and sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com