Production method of hollow turbine vane with shaped air film hole

A technology for turbine blades and manufacturing methods, which is applied in the field of manufacturing hollow turbine blades, and can solve problems affecting blade fatigue life, blade fatigue fracture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

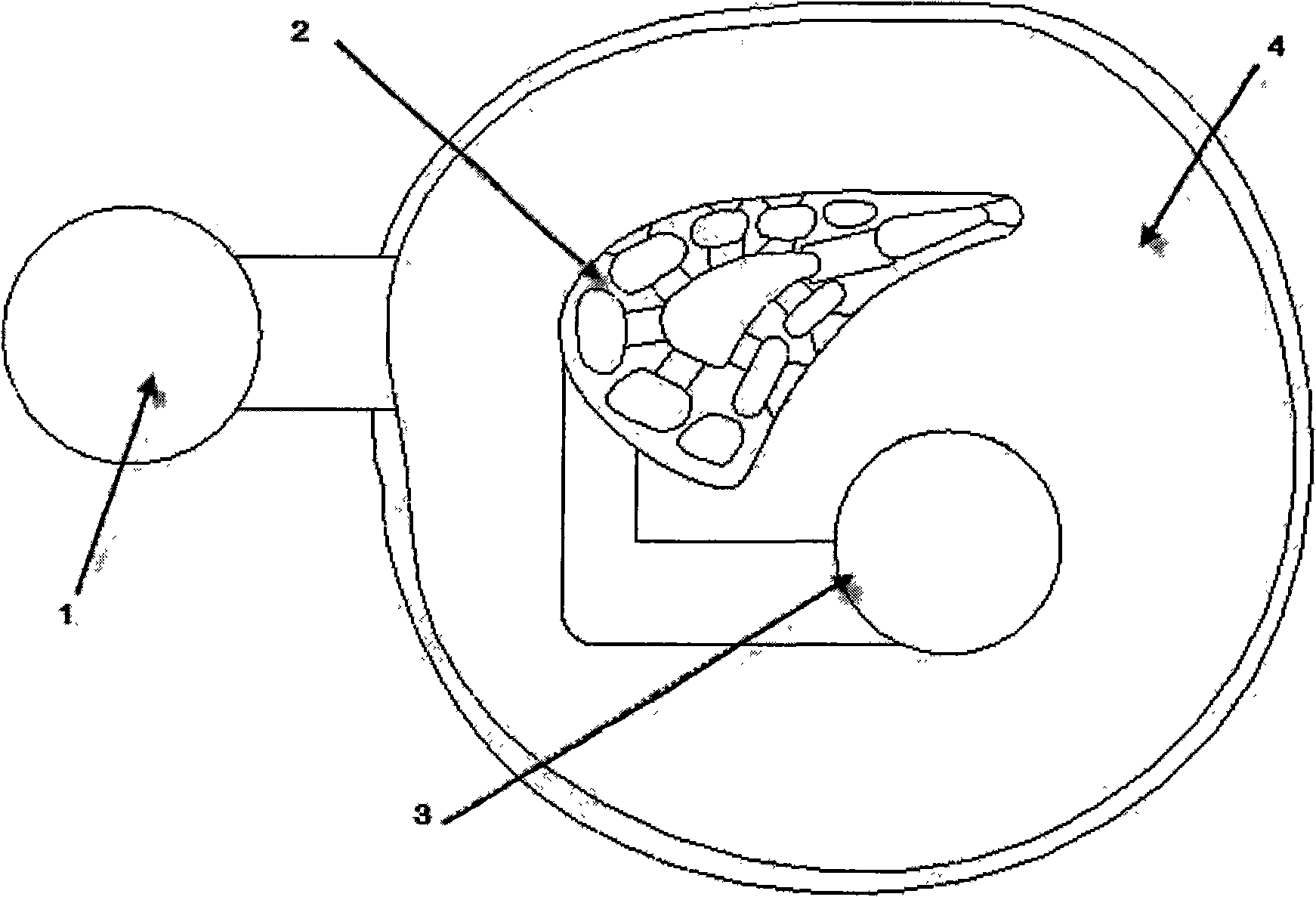

[0019] Example 1, see figure 1 , 1) Manufacture resin mold

[0020] The resin mold in this embodiment mainly consists of four parts, including ceramic slurry injection system prototype 1, hollow turbine blade prototype 2 with special-shaped air film holes, metal pouring system prototype 3 and mold cavity 4. The hollow turbine blade prototype 2 with special-shaped air film holes has a complex cooling structure inside, and there are many special-shaped air film holes on the outer surface. Through the ceramic slurry pouring system prototype 1, the ceramic slurry is smoothly filled into the mold cavity 4 and the internal cooling channel of the hollow turbine blade prototype 2 and the special-shaped air film holes on the outer surface. The mold cavity 4 is the mold shell of the ceramic casting mold, and its size is controlled between 6-8 mm, so as to avoid being too thick and affecting the metallurgical process performance of the ceramic casting mold and affecting the quality of t...

Embodiment 2

[0037] Example 2: Prepare ceramic slurry in this example: first dissolve organic matter in deionized water, add dispersant and uniformly mixed ceramic powder and mineralizer powder in turn to make ceramic slurry, add initiator and catalyst before pouring , mixed evenly and vacuumed to remove the air bubbles in the ceramic slurry to make a ceramic slurry with a viscosity of less than 1Pa S and a linear shrinkage rate of less than 0.5%; pour the ceramic slurry into the cavity of the hollow turbine blade prototype resin mold through the pouring system In the process, the hollow turbine blade prototype resin mold surface is filled with special-shaped air film holes and internal cooling channels, and the internal and external structures of the hollow turbine blade prototype are copied;

[0038] Among them, the ceramic powder adopts fused corundum powder with a particle size of 1-60 μm;

[0039] The mineralizer powder adopts magnesium oxide and yttrium oxide mixed in a mass ratio of...

Embodiment 3

[0045] Example 3: Preparation of ceramic slurry in this example: First, dissolve organic matter in deionized water, add dispersant and uniformly mixed ceramic powder and mineralizer powder in turn to make ceramic slurry, add initiator and catalyst before pouring , mixed evenly and vacuumed to remove the air bubbles in the ceramic slurry to make a ceramic slurry with a viscosity of less than 1Pa S and a linear shrinkage rate of less than 0.5%; pour the ceramic slurry into the cavity of the hollow turbine blade prototype resin mold through the pouring system In the process, the hollow turbine blade prototype resin mold surface is filled with special-shaped air film holes and internal cooling channels, and the internal and external structures of the hollow turbine blade prototype are copied;

[0046] Among them, the ceramic powder adopts fused corundum powder with a particle size of 1-60 μm;

[0047] The mineralizer powder adopts magnesium oxide and yttrium oxide mixed in a mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com