A kind of preparation method of titanium-based composite structure material

A composite structure, titanium-based technology, applied in metal processing equipment, transportation and packaging, etc., can solve problems such as thermophysical differences increase the difficulty of compounding, difficulty in controlling casting precision, and limit large-scale applications, etc., and achieve good deformation processing performance , Simplified production process, and high interface connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present invention comprises the following steps:

[0027] S1. Select pure titanium with low oxygen content, the median particle size is 25 μm, and the oxygen content is 0.15%;

[0028] S2, mixing titanium powder with a binder with a foaming agent to prepare the feed; the binder is selected from polyoxymethylene, polyethylene, polypropylene; the foaming agent is selected from TiH2; wherein polyoxymethylene, polyethylene, polypropylene, The foaming agent accounts for 10%, 2%, 3%, and 2% of the weight of titanium powder respectively;

[0029] S3. Obtain the green body by injection molding; wherein the technical parameters are: mold temperature 120°C, material temperature 180°C, pressure 130MPa;

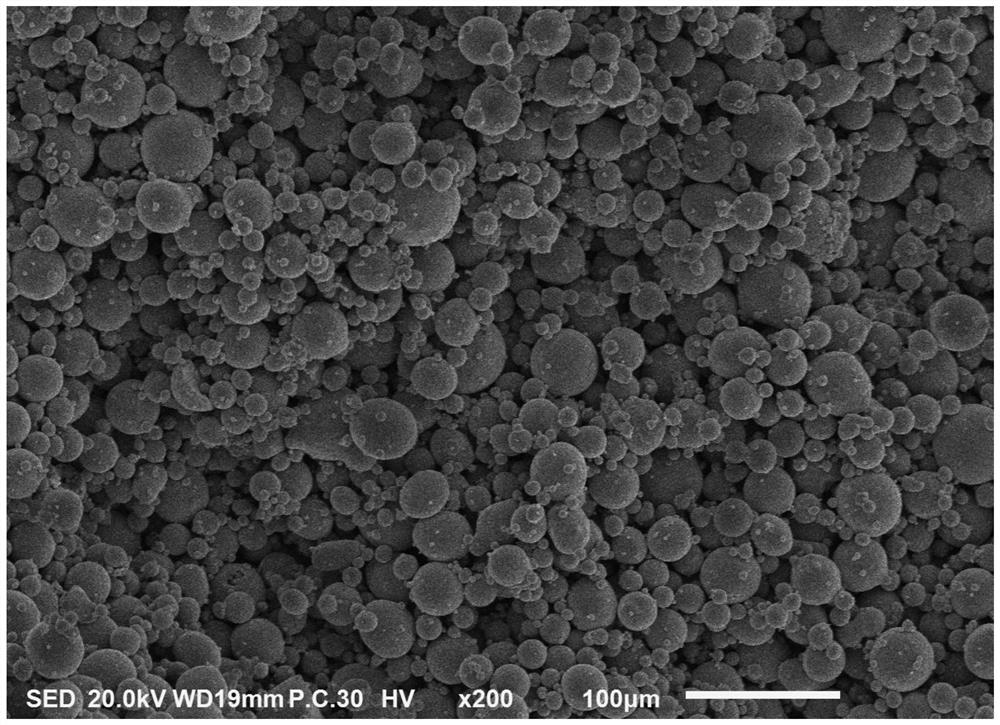

[0030] S4, carry out degreasing by atmosphere degreasing process, its technical parameter is: degreasing temperature is 600 ℃, and degreasing atmosphere is argon; figure 1 );

[0031] S5, sintering under a vacuum condition of 1100° C. to obtain a porous titanium body;

[0...

Embodiment 2

[0035] The present invention comprises the following steps:

[0036] S1. Select TC4 powder with low oxygen content, the median particle size is 50 μm, and the oxygen content is ≤0.2%;

[0037] S2, TC4 powder is mixed with the binding agent that has foaming agent to prepare granulated powder; Binding agent selects polyvinyl alcohol; Foaming agent selects ammonium chloride; Wherein polyvinyl alcohol and ammonium chloride account for TC4 powder weight respectively 3%, 2%;

[0038] S3. Obtain the green body by pressing and forming, wherein the technical parameters are: pressure 100MPa, room temperature, holding time 2s;

[0039] S4. Degreasing through the atmosphere degreasing process, the technical parameters are: the degreasing temperature is 200°C, and the degreasing atmosphere is argon; during the degreasing process, the binder is removed, and the foaming agent further fluffs the powder into a porous structure;

[0040] S5, sintering under a vacuum condition of 1250° C. to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com