Precision casting molding method for complex thin-walled member

A technology of precision casting and forming method, which is applied in the precision casting and forming of complex thin-walled castings, and can solve the problems of waste of metal materials, energy consumption and man-hours, and low production efficiency, so as to improve the cost performance of products and achieve huge economic Benefit, the effect of saving a lot of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

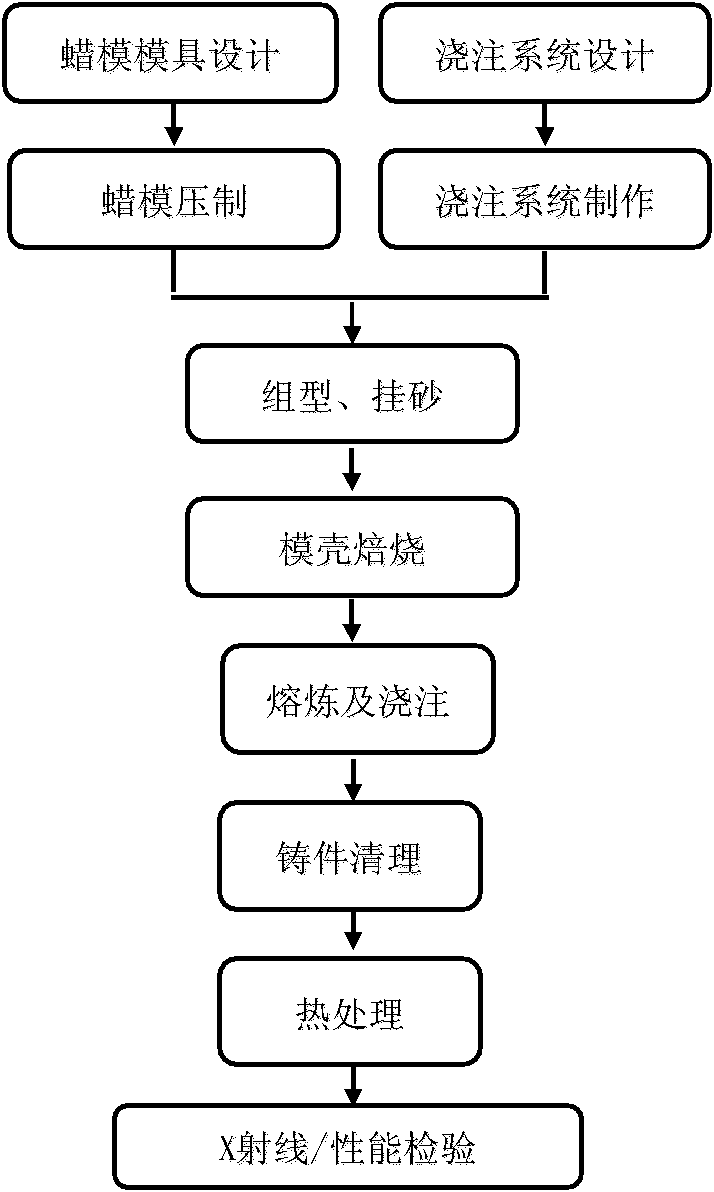

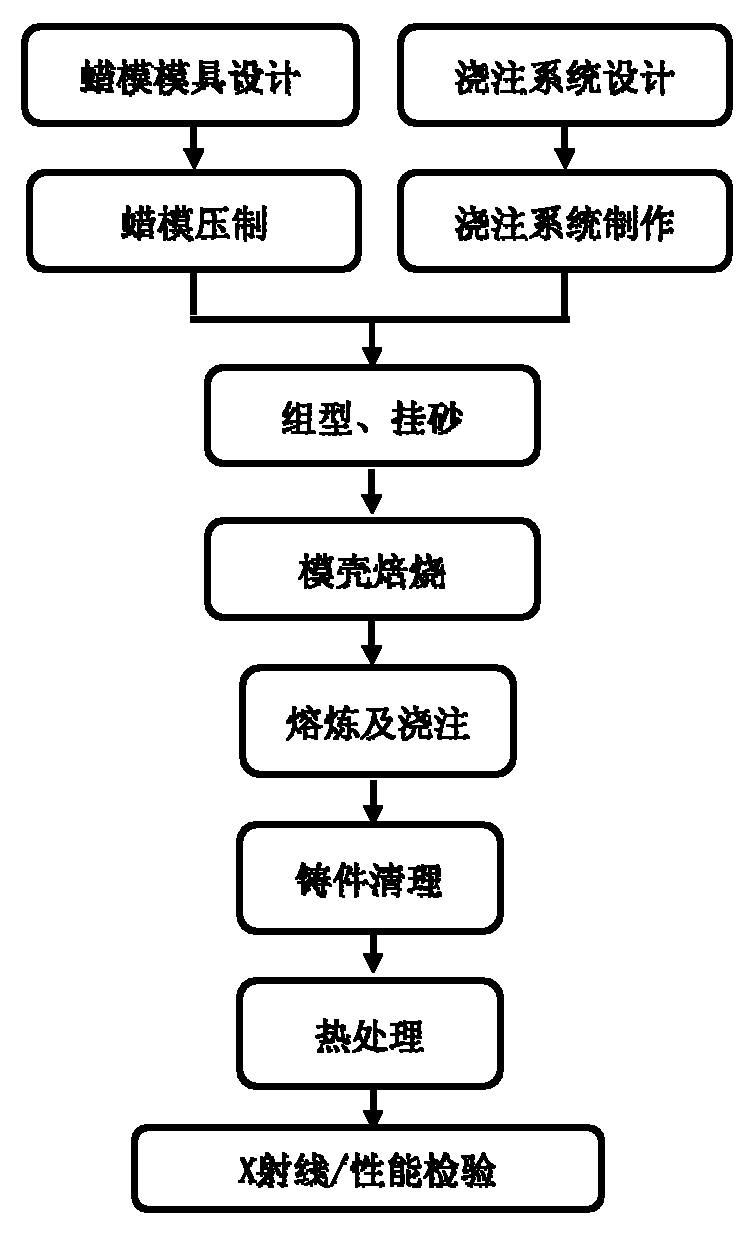

[0035] According to this embodiment figure 1 The process flow chart shown is carried out, the specific steps are as follows:

[0036] 1) Design and manufacture of wax molds: design and manufacture metal wax molds according to the upper tube socket of the nuclear reactor, specifically, the draft angle is determined to be 3', and the shrinkage of the casting is 1.5%;

[0037] 2) Press the wax mold: Use the wax mold mold made in the previous step and the wax press machine to press the wax mold of the upper tube seat of the nuclear reactor, the pressing temperature is 70 ° C, and the pressing pressure is 0.4 MPa;

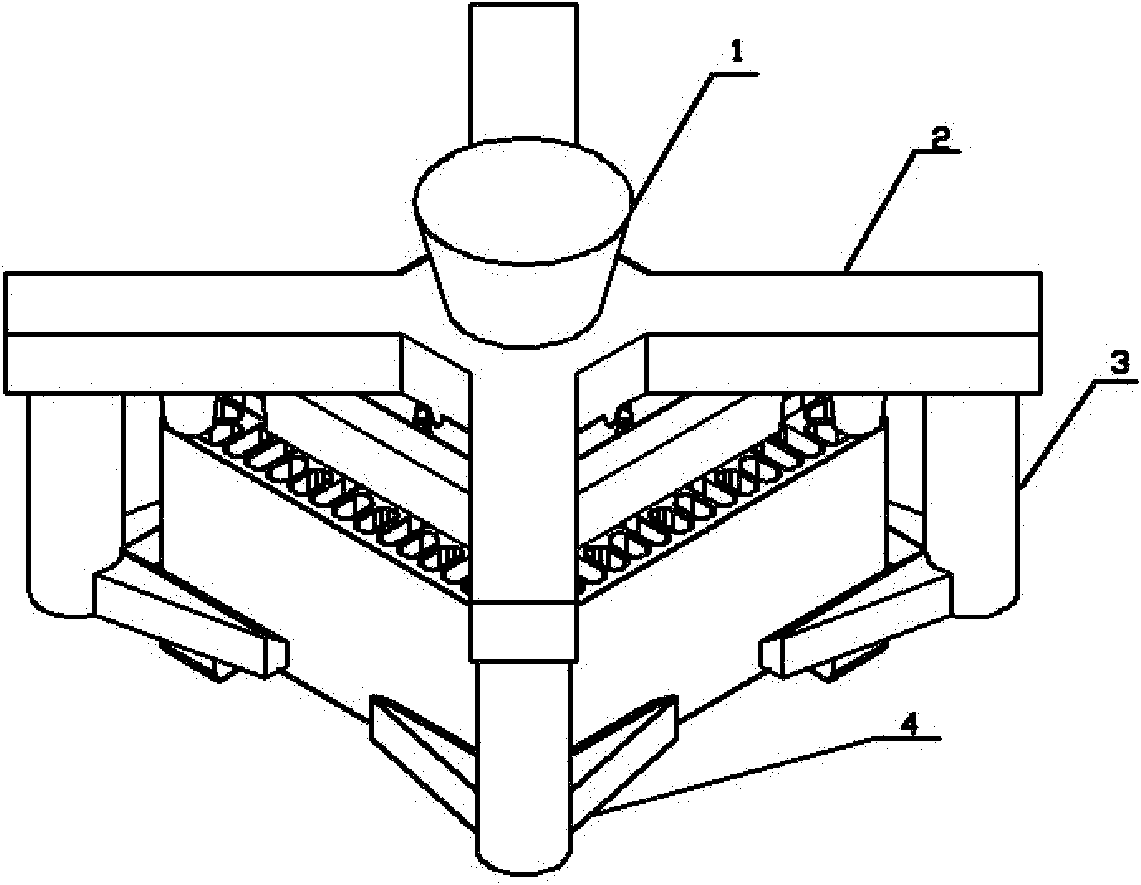

[0038] 3) Design and production of pouring system: the structure of pouring system is as follows: figure 2 As shown, a wax press machine is used to press the above-mentioned sprue cup 1, cross runner 2, sprue 3 and ingate 4 respectively;

[0039] 4) Group type: Use liquid wax to make the wax mold pressed in step 2) and the sprue cup 1, cross runner 2, sprue 3 and ing...

Embodiment 2

[0048] 1) Design and manufacture of wax molds: design and manufacture metal wax molds based on the sockets of nuclear reactors. Specifically, the draft angle is determined to be 1.5°, and the casting shrinkage is 2.3%;

[0049] 2) Press the wax mold: use the wax mold mold made in the previous step and the wax press machine to press the wax mold of the upper tube seat of the nuclear reactor, the pressing temperature is 75 ° C, and the pressing pressure is 0.55 MPa;

[0050] 3) Design and production of pouring system: the structure of pouring system is as attached figure 2 As shown, a wax press machine is used to press the above-mentioned sprue cup 1, cross runner 2, sprue 3 and ingate 4 respectively;

[0051] 4) Group type: Use liquid wax to make the wax mold pressed in step 2) and the sprue cup 1, cross runner 2, sprue 3 and ingate 4 pressed in the third step according to the attached figure 2 The structure shown is bonded to form a whole;

[0052] 5) Sand hanging: use 70 ...

Embodiment 3

[0060] 1) Design and manufacture of wax molds: Design and manufacture metal wax molds according to the upper tube socket of the nuclear reactor. Specifically, the draft angle is determined to be 3°, and the shrinkage of the casting is 3%;

[0061] 2) Wax mold pressing: Use the wax mold mold and wax press machine made in the previous step to press the wax mold of the upper tube seat of the nuclear reactor, the pressing temperature is 80°C, and the pressing pressure is 0.7MPa;

[0062] 3) Design and production of pouring system: the structure of pouring system is as attached figure 2 As shown, a wax press machine is used to press the above-mentioned sprue cup 1, cross runner 2, sprue 3 and ingate 4 respectively;

[0063] 4) Group type: Use liquid wax to make the wax mold pressed in step 2) and the sprue cup 1, cross runner 2, sprue 3 and ingate 4 pressed in the third step according to the attached figure 2 The structure shown is bonded to form a whole;

[0064] 5) Sand hangi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com