Fermentation tank

A fermenter and flexible wall technology, applied in the field of fermentation devices, can solve the problems of inability to complete the hollow fiber membrane, the need for regular cleaning and replacement, pollution, etc., to reduce the degree of concentration polarization and blockage, facilitate the colonization of microorganisms, improve The effect of reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

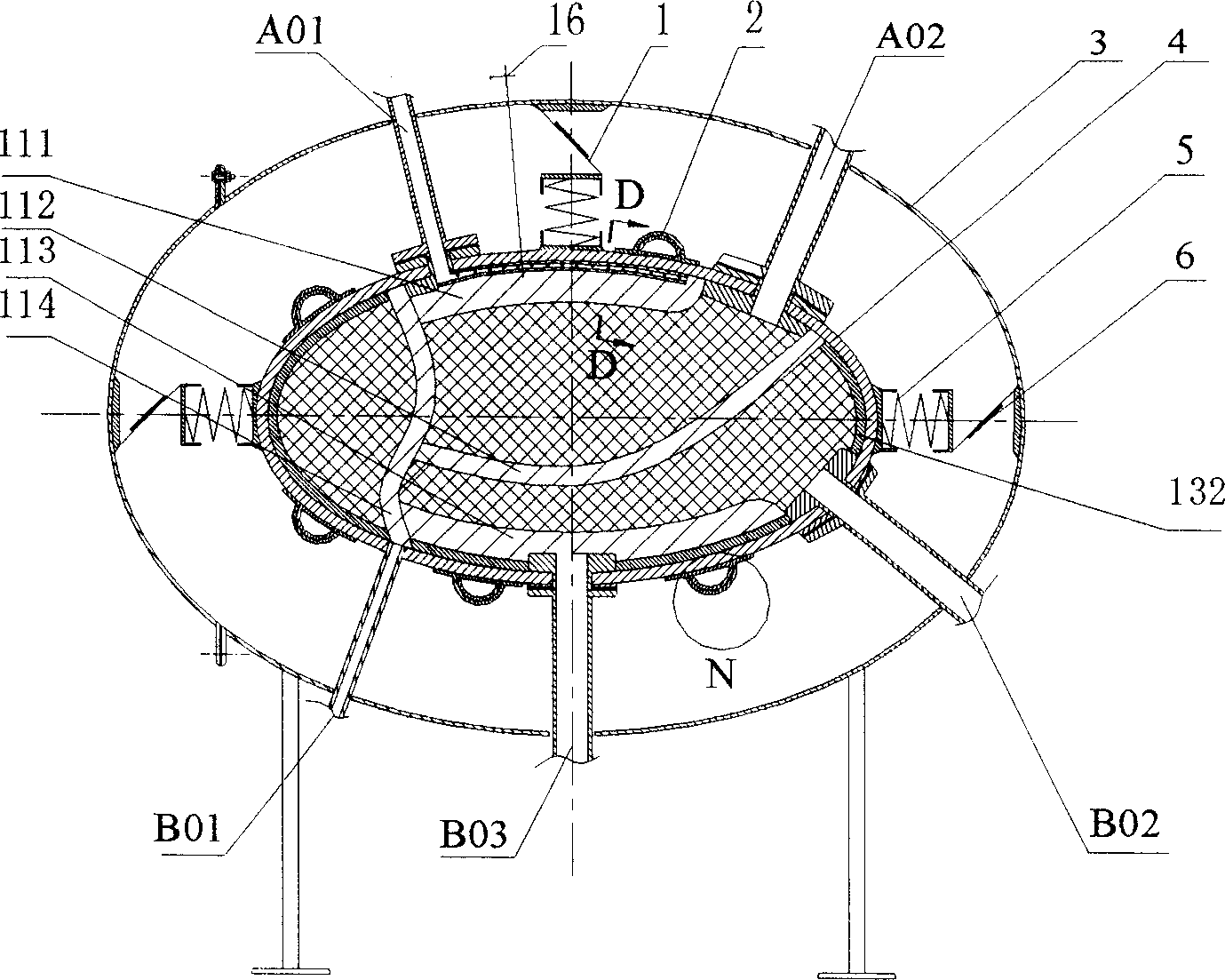

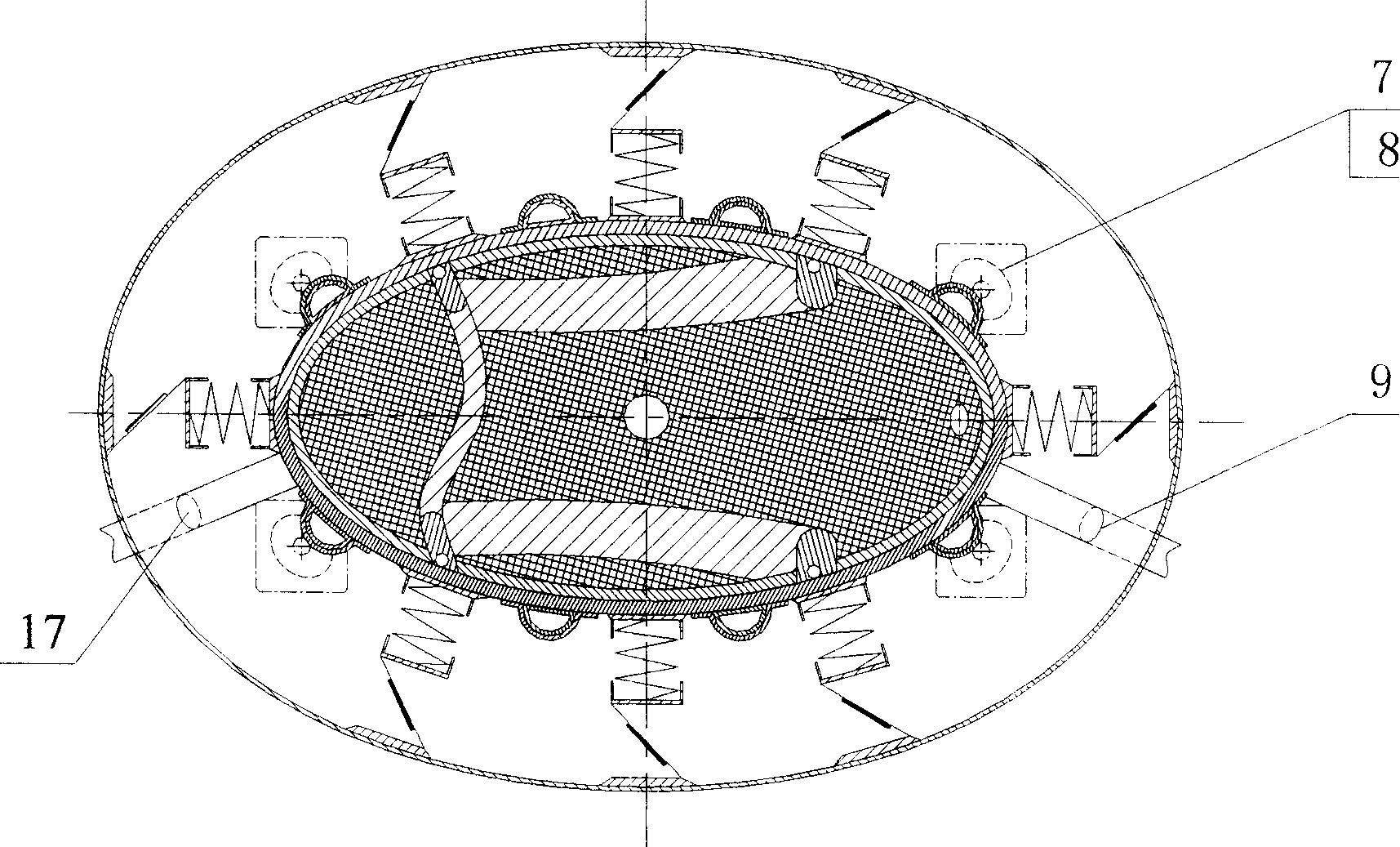

[0022] refer to Figure 1 to Figure 4 , what is described below is a preferred embodiment of a peristaltic fermenter that can be used for solid substrates for 5 liters. The flexible wall (4) built into the supporting outer wall (3) is a hollow ellipsoid, working under long pressure , its long axis is 322 mm, its short axis is 185 mm, and its volume is 5.77 liters, which can ensure the volume of fermentation liquid to reach 5 liters except for the space required for part of the metabolic gas.

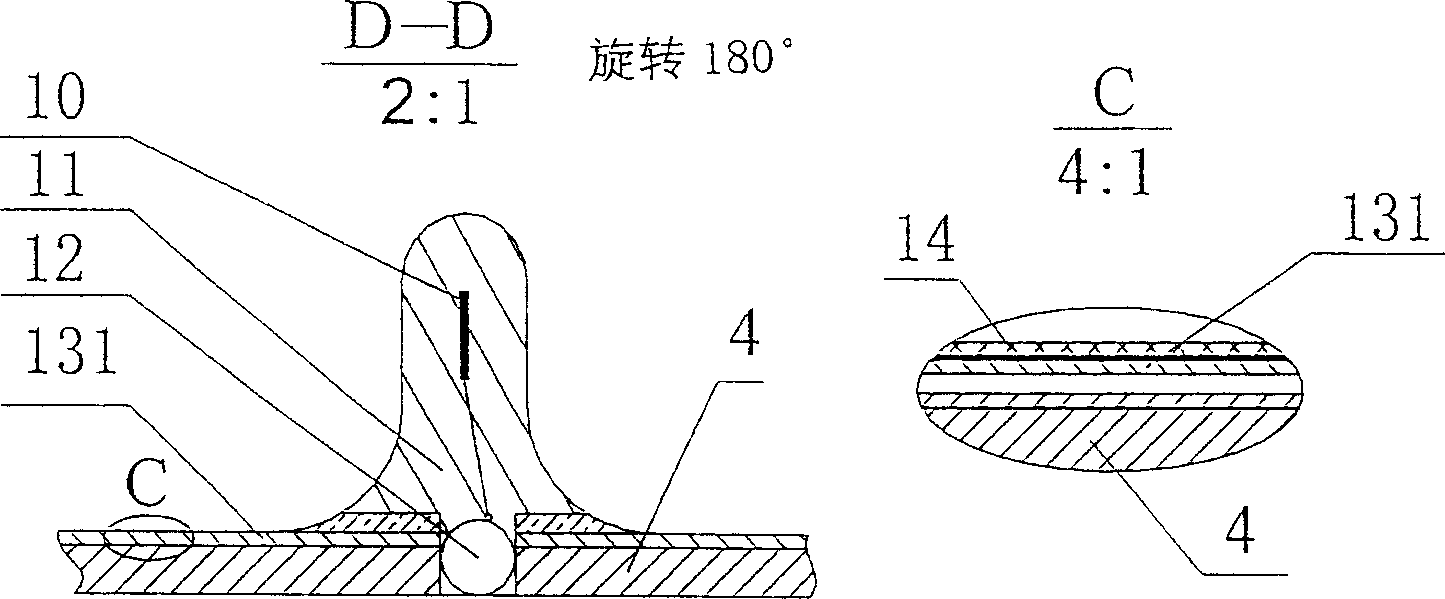

[0023] The flexible wall (4) is made of precision casting mold silicone rubber. It is divided into upper and lower parts when making it, that is, the semi-ellipsoid body in the upper half and the semi-ellipsoid body in the lower part. The wall thickness is 3mm. It can be hand-made for cost saving, and it can be die-casted in mass production. What is first made of silicon rubber with a precision casting mold is the blank of the flexible wall (4). On the inner surface of the blank part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com