Parametric machining method of air film cooling holes for precision casting turbine blades

A turbine blade and air film cooling technology, which is applied in the field of turbine blades, can solve the problems of low forming precision and unstable quality of air film holes, and achieve the effect of improving cooling efficiency and processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0043] This embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation methods and processes. But the scope of protection of the present invention is not limited to the following examples.

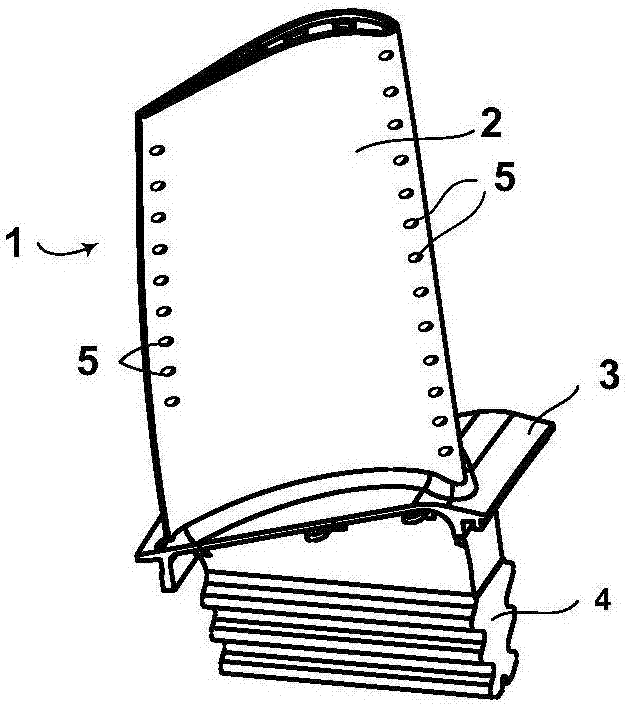

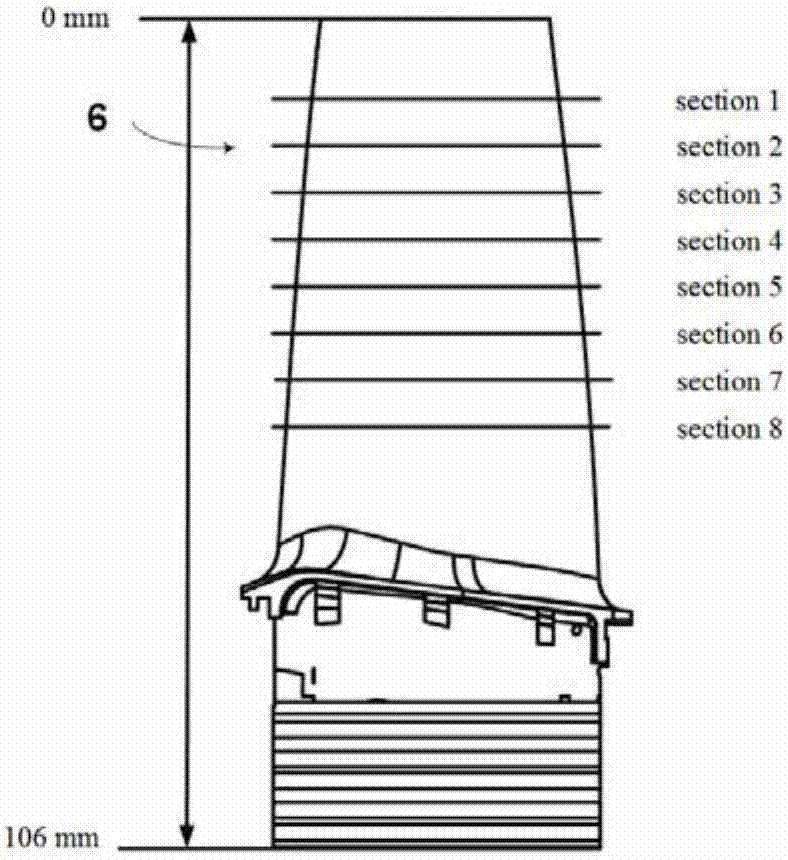

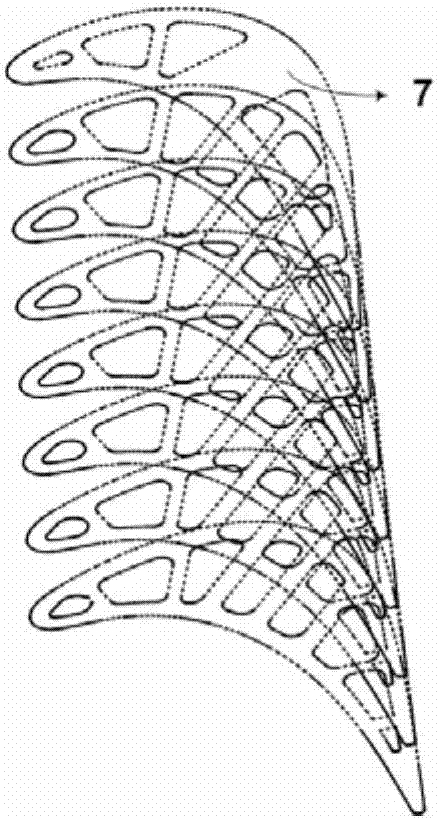

[0044] step 1

[0045] A film-cooled hollow turbine blade such as figure 1 shown. The main geometric parameters of the hollow turbine blade design model 1 are blade body length 101 mm, maximum chord length 59.21 mm, maximum inscribed circle radius 5.67 mm, and trailing edge radius 1.27 mm. Model 1 includes blade profile 2 , rafter plate 3 , tenon 4 , and air film hole 5 that meet aerodynamic requirements. The geometric information of the film hole 5 is obtained from the model 1 given by the design department, including: the hole diameter of the film hole, the hole depth, and the coordinates o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com