Waxless precision casting process

a precision casting and waxless technology, applied in the field of investment casting, can solve the problems of not being able to meet the design requirements of components, the cost of investment casting, and the inability to manufacture such blades economically with existing technology, so as to achieve the effect of improving the green body strength, facilitating the production of cores, and high failure ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Exemplary Casting Process

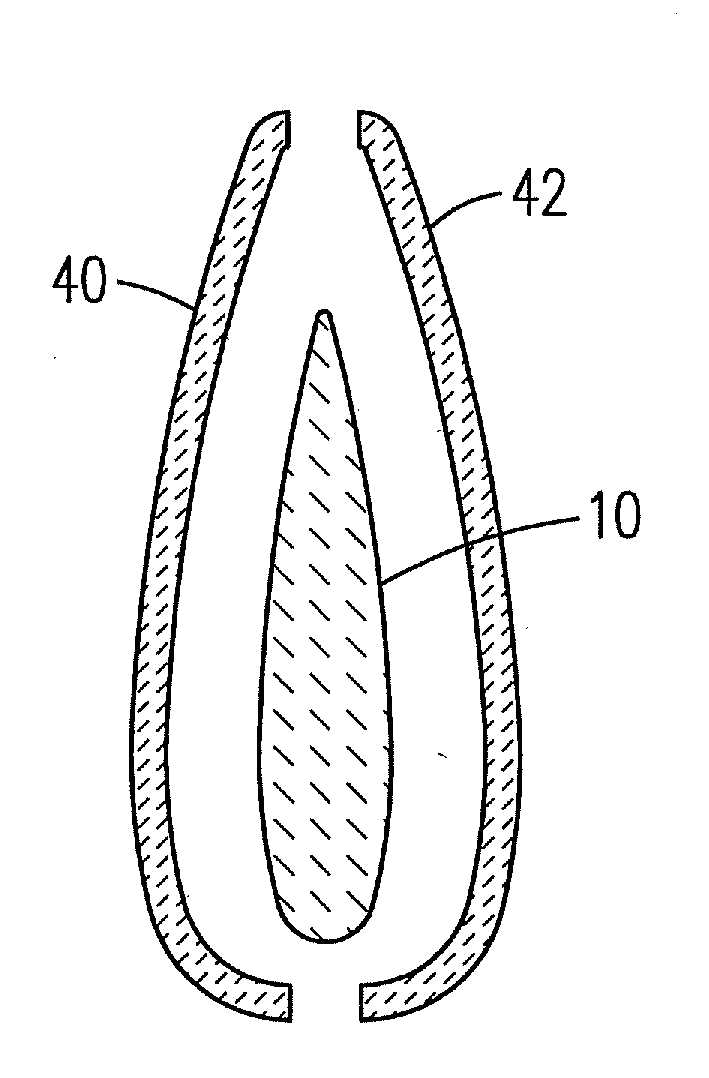

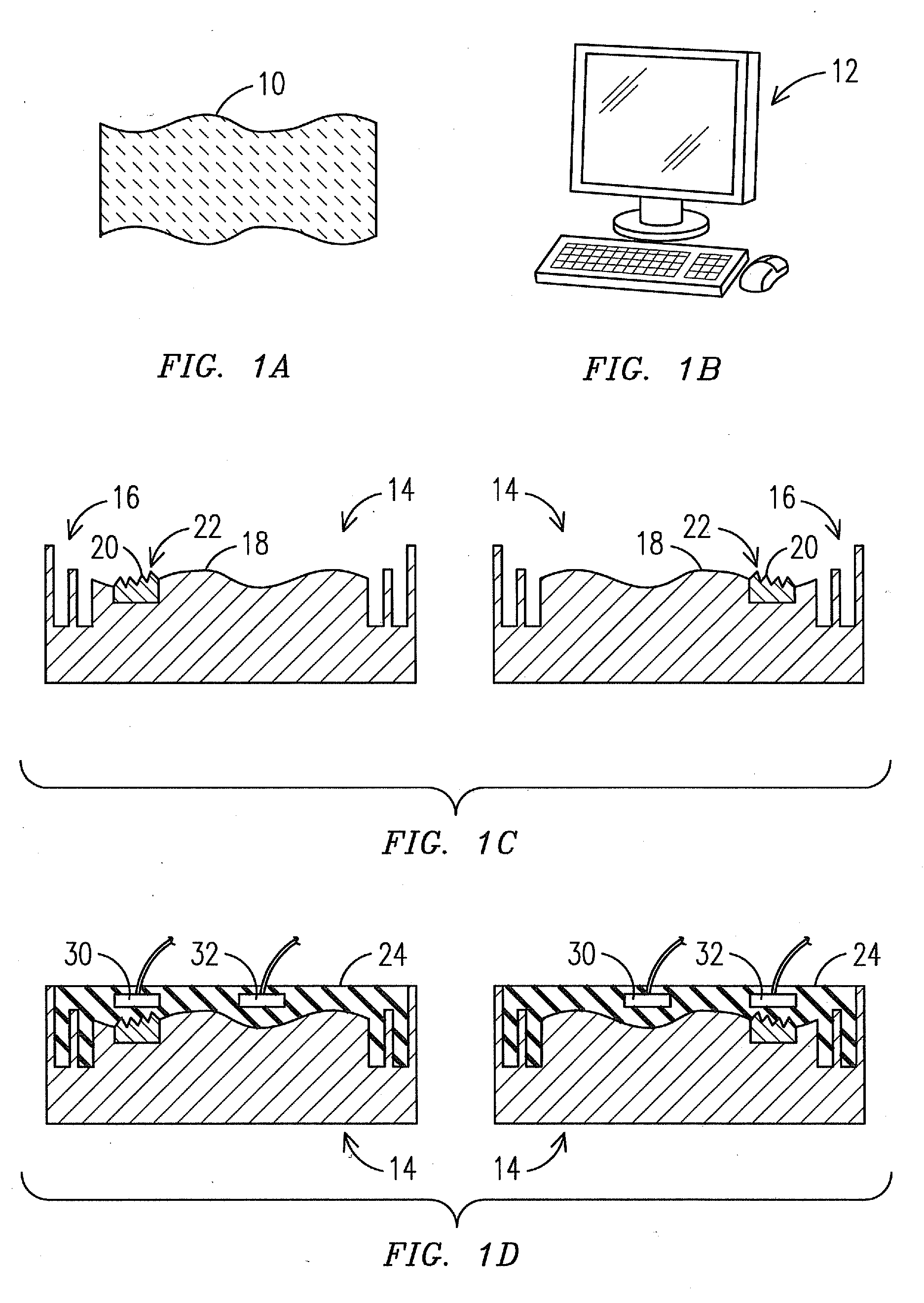

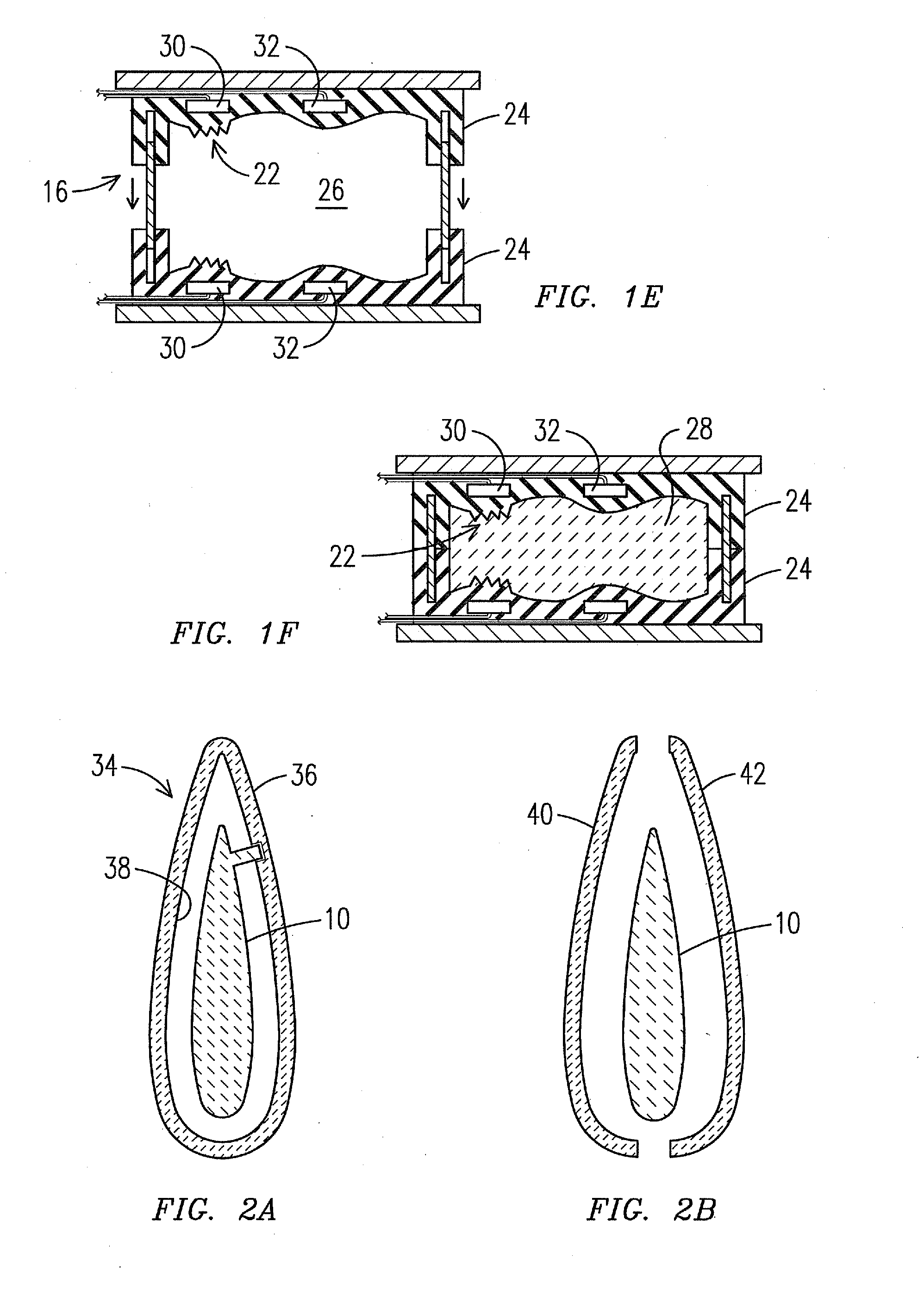

[0027]The waxless precision casting process disclosed herein includes the use of relatively inexpensive master tools made from easily machined soft alloy material, such as aluminum, with optional high precision feature inserts. The master tools are used to cast intermediate flexible molds, which in turn are used to cast respective sections of a ceramic casting vessel. The vessel sections are then assembled to form a complete ceramic casting vessel, with precise alignment of the sections facilitated by cooperating alignment features.

[0028]An exemplary embodiment of the invention discussed herein is the fabrication of a gas turbine blade, which is a hollow alloy component having interior cooling passages; however, one will appreciate that the invention is not so limited and may be used for the fabrication of various hollow and solid components. The present waxless casting process is first described in part under this subheading with reference made to the fabri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com