Preparation method of tial alloy bar

A technology of alloy rods and alloys, which is applied in the field of preparation of TiAl alloy rods, can solve problems such as hot extrusion difficulties, TiAl alloy rods are easy to introduce impurities, and low density, so as to achieve uniform and fine grains and avoid deformation coordination Poor performance, to avoid the effect of surface oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of Ti-48Al-2Cr-2Nb-3Ni alloy bar is as follows:

[0032] (1) Weigh the raw materials: the composition is 48% Al, 2% Nb, 2% Cr, 3% Ni, and the balance Ti and unavoidable impurities according to the atomic percentage of each element. Weigh 18,000 g of sponge titanium, pure aluminum, high-purity chromium, high-purity nickel, and aluminum-niobium alloy (54.56% Nb content) as raw materials.

[0033] (2) Melting and casting ingots: Put the sponge titanium, pure aluminum, high-purity chromium, high-purity nickel and aluminum-niobium alloy weighed in step 1 into a water-cooled copper crucible induction condensing shell melting furnace for smelting, and the vacuum degree is 1.0×10 -3 mbar; then poured into the preheated metal mold to obtain an ingot.

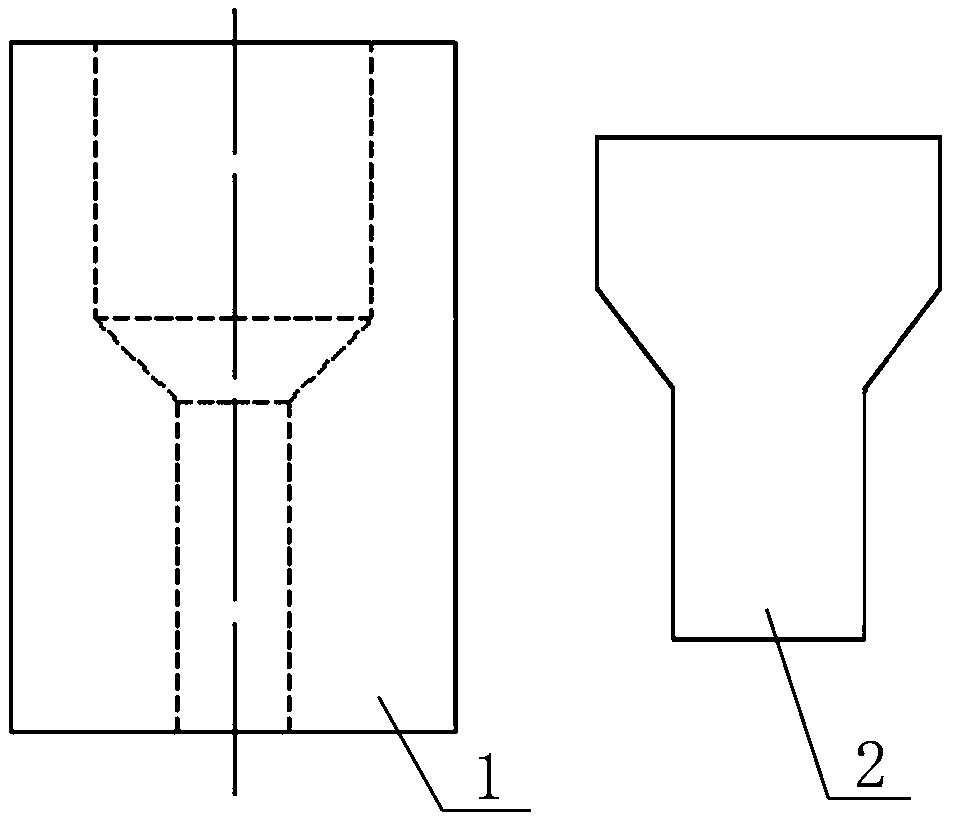

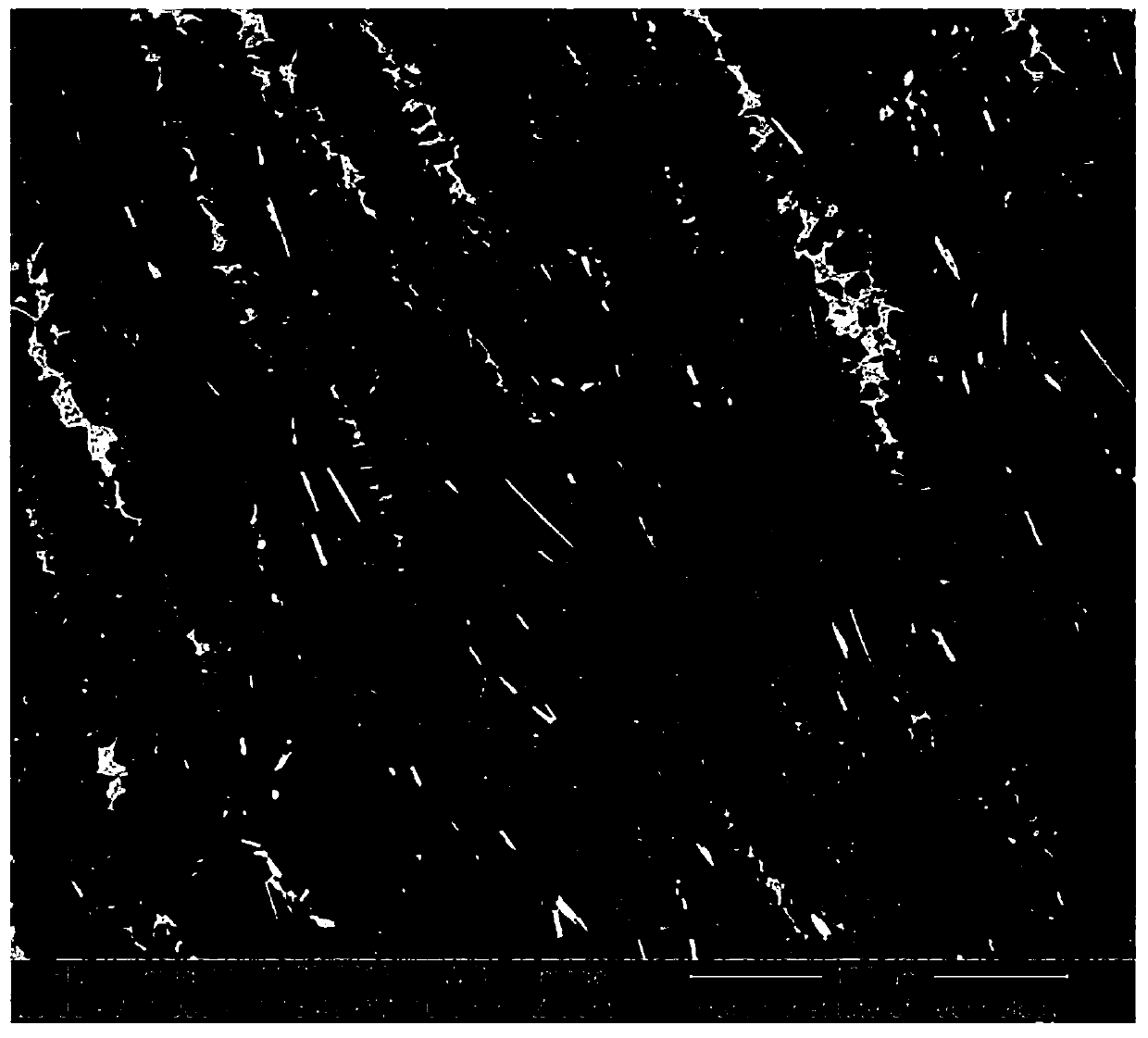

[0034] (3) Pretreatment of the extruded billet: a. The TiAl alloy ingot is processed by hot isostatic pressing. The hot isostatic pressing process parameters are 1250℃, 150MPa, argon atmosphere protection, heat pre...

Embodiment 2

[0037] The preparation method of Ti-45Al-5Nb alloy bar is as follows:

[0038] (1) Weigh the raw materials: according to the atomic percentage of each element, the composition is 45% Al, 5% Nb, the balance is Ti and inevitable impurities. Weigh respectively 18000g of sponge titanium, pure aluminum and aluminum-niobium alloy (with 54.56% Nb content) as raw materials.

[0039] (2) Melting and casting: Add the sponge titanium, pure aluminum and aluminum-niobium alloy weighed in step 1 into a water-cooled copper crucible induction smelting furnace for smelting, and the vacuum degree is 3.0×10 -3 mbar; then poured into the preheated metal mold to obtain an ingot.

[0040] (3) Pretreatment of the extrusion billet: a. The TiAl alloy ingot is processed by hot isostatic pressing, the hot isostatic pressing process parameter is 1250℃, 155MPa, and argon atmosphere protection (the quality of argon is 99.99%) , Heat preservation for 5h, cool out with the furnace, then put the ingot in a box-type...

Embodiment 3

[0044] The preparation method of Ti-43Al alloy bar is as follows:

[0045] (1) Weigh the raw materials: the composition is 43% Al according to the atomic percentage of each element, and the balance is Ti and unavoidable impurities. Weigh 18,000 g of sponge titanium and pure aluminum as raw materials.

[0046] (2) Melting and casting: Add the sponge titanium, pure aluminum and aluminum-niobium alloy weighed in step 1 into a water-cooled copper crucible induction shell melting furnace for smelting, and the vacuum degree is 2.0×10 -3 mbar; then poured into the preheated metal mold to obtain an ingot.

[0047] (3) Pretreatment of the extrusion billet: a. The TiAl alloy ingot is processed by hot isostatic pressing, the hot isostatic pressing process parameters are 1280 ℃, 160 MPa, and argon atmosphere protection (the quality of argon is 99.99%) , Heat preservation for 4h, cool out with the furnace, then place the ingot in a box-type muffle furnace, keep it at 1000°C for 24h, air cooling;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com