Damping type steel structure node component

A technology of steel structure and joints, which is applied in the direction of building components, earthquake resistance, building construction, etc., can solve problems such as bolt breakage and poor shock absorption, and achieve the effect of preventing direct collision and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

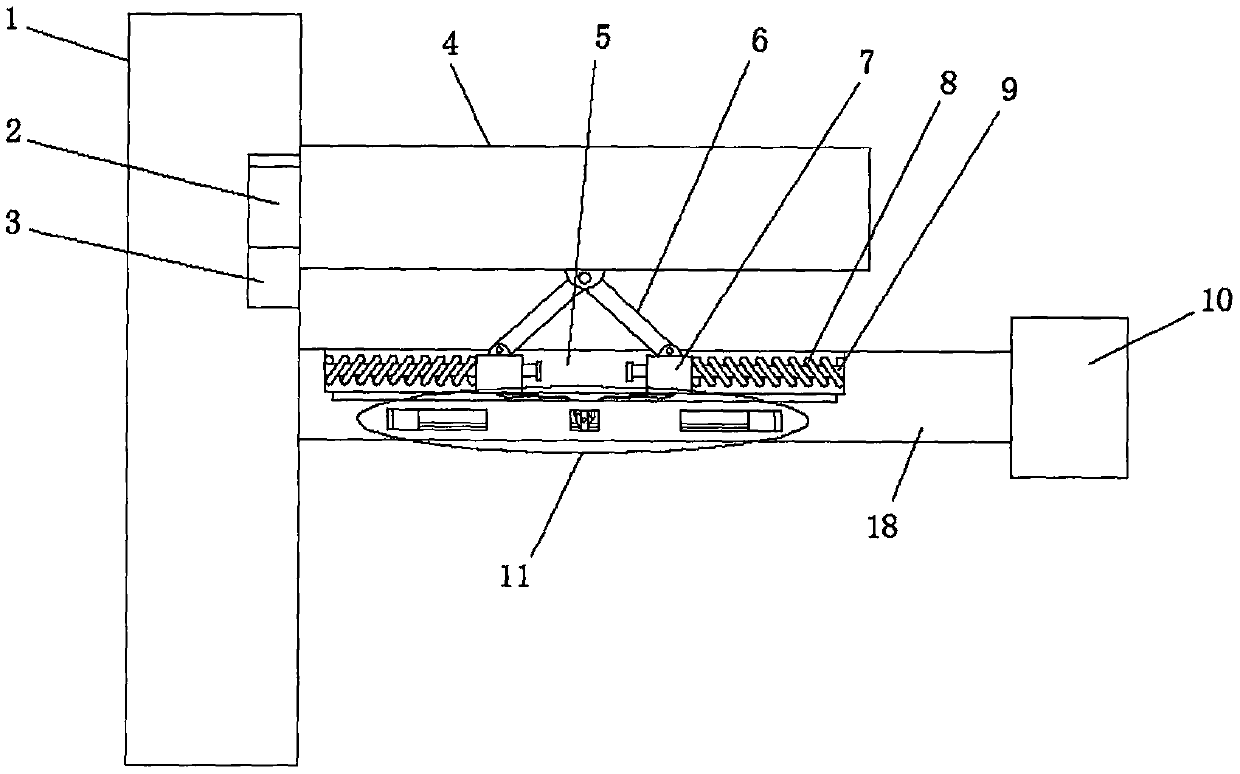

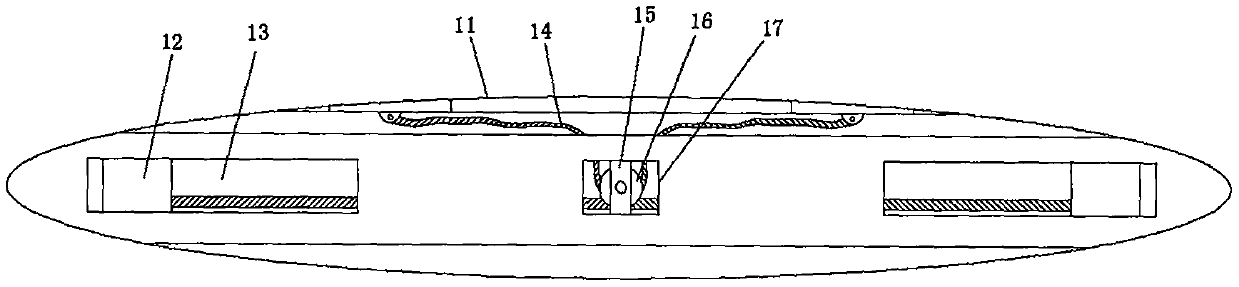

[0020] Embodiment: When in use, when the steel structure is subjected to shear force, the shock-absorbing steel plate 4 will drive the limit block 2 to slide in the limit groove 3, and will squeeze the hinge rod 6, and the hinge rod 6 will push the movable block 7 Slide in the movable groove 5, and the movable block 7 will slide on the guide rod 9, so that the movable block 7 squeezes the spring 8 sleeved on the guide rod 9, and the elastic force of the spring 8 provides a buffer for the steel structure node. Shock protection, and in the process that the movable block 7 continues to move, the movable block 7 will drive the stay cord 14, so that the stay cord 14 slides on the circumferential side wall of the guide wheel 16, and the stay cord 14 will pull the slide block 12 in the chute 13, when the slider 12 is in contact with the side wall of the chute 13, the shock-absorbing steel plate 4 of the shock-absorbing buffer protection device of the steel structure node will stop mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com