Anionic water-based non-curing rubber asphalt waterproof coating and preparation method thereof

A technology of asphalt waterproof coating and non-curing rubber, which is applied in the direction of asphalt coating, coating, etc., can solve the problems of unfavorable environmental protection requirements, poor storage performance, complicated process, etc., and achieve the effect of solving the problem of water channeling, stable storage, and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

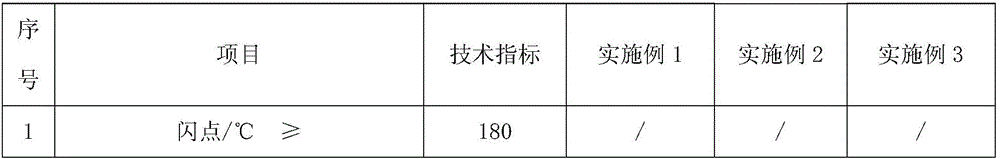

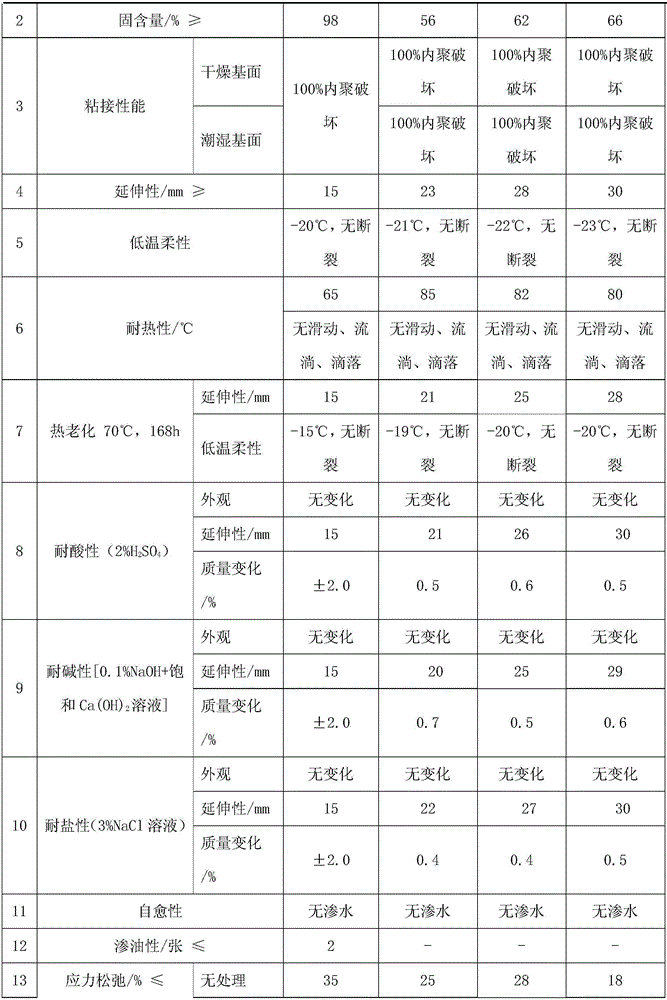

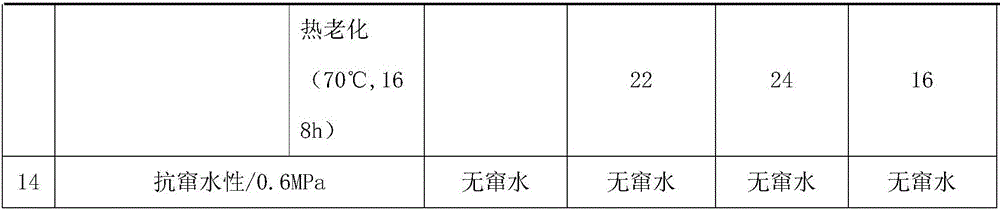

Examples

Embodiment 1

[0016] An anionic water-based non-curing rubber asphalt waterproof coating, which is composed of component A and component B, wherein component A is composed of 88 parts by mass of anionic rubber modified emulsified asphalt, 3 parts by mass of SBR latex, and 7 parts by mass of chlorine Butadiene latex, 0.5 mass parts of wax emulsion, 1.5 mass parts of graphene aqueous slurry; component B is composed of 10 mass parts of calcium chloride, 90 mass parts of water; the mass ratio of component A to component B is 6:1.

[0017] The anionic rubber-modified emulsified asphalt in component A consists of base asphalt, tackifier, rubber elastomer, anionic emulsifier, stabilizer, and pH regulator with a mass ratio of 30:15:4:5:0.1:0.3:45.6 It is emulsified with water through a colloid mill. The base asphalt is No. 70 petroleum asphalt, the tackifier is aromatic oil, the rubber elastomer is SBS, the stabilizer is polyacrylate, the anionic emulsifier is sulfate anionic emulsifier, and the p...

Embodiment 2

[0025] An anionic water-based non-curing rubber asphalt waterproof coating consists of component A and component B. Component A consists of 90 parts by mass of anionic rubber-modified emulsified asphalt, 4 parts by mass of SBR latex, 5 parts by mass of neoprene latex, 0.5 parts by mass of wax emulsion, and 0.5 parts by mass of graphene aqueous slurry; component B consists of 20 parts by mass of calcium chloride and 80 parts by mass of water; the mass ratio of component A to component B is 8:1.

[0026] The anionic rubber-modified emulsified asphalt in component A consists of base asphalt, tackifier, rubber elastomer, anionic emulsifier, stabilizer, NaOH and The base asphalt is No. 90 petroleum asphalt, the tackifier is aromatic oil, the rubber elastomer is SEBS, the stabilizer is polyacrylate, the anionic emulsifier is sulfate anionic emulsifier, and the pH regulator is NaOH.

[0027] A preparation method of anionic water-based non-curing rubber asphalt paint, comprising the fo...

Embodiment 3

[0034] An anionic water-based non-curing rubber asphalt waterproof coating, consisting of component A and component B;

[0035] Component A consists of 92 parts by mass of anionic rubber-modified emulsified asphalt, 2.5 parts by mass of SBR latex, 4 parts by mass of neoprene latex, 0.5 parts by mass of wax emulsion, and 1 part by mass of graphene aqueous slurry; component B is made up of the calcium chloride of 30 mass parts, the water of 70 mass parts; The mass ratio of component A and component B is 12:1;

[0036] The anionic rubber-modified emulsified asphalt in component A consists of base asphalt, tackifier, rubber elastomer, anionic emulsifier, stabilizer, NaOH and water with a mass ratio of 25:25:6.5:7.5:0.3:0.4:35.3 composition. The base asphalt is No. 90 petroleum asphalt, the tackifier is aromatic oil, the rubber elastomer is SIS, the stabilizer is polyacrylate, the anionic emulsifier is sulfate anionic emulsifier, and the pH regulator is NaOH.

[0037] A preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com